This article is part of the FLEXO FLAW FIXING series

If you are looking for information about bleeding and smudging in flexo printing, you have come to the right place. This article explains what this process does and how it works.

It is also discussed why it can be problematic if not done correctly, as well as some possible solutions to avoid prolonged bleeding.

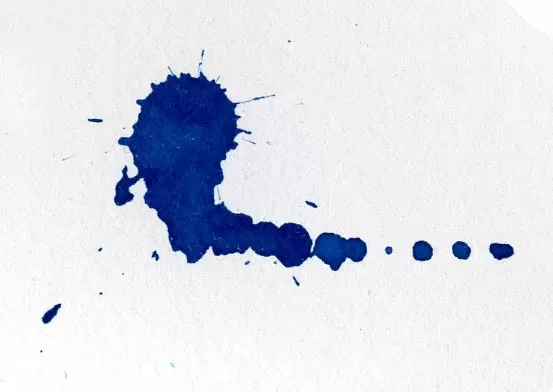

What is bleeding / smudging in flexo printing?

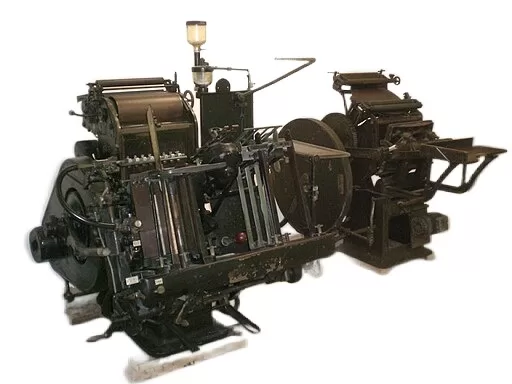

It is common for prints to bleed or smudge during the printing process, which can adversely affect the quality of the print. An ink roller is responsible for depositing large amounts of ink evenly and quickly onto the paper in flexo printing.

Smudging occurs when too small or too large ink droplets bleed together.

How does bleeding and smudging occur in flexo printing?

In printing, bleeding is the liquid that comes out of the print heads. Smudging occurs when the ink moves and accumulates powder on the print heads and on the material.

Smudging and bleeding can occur in any flexo printing process, but most commonly on rotary and cylinder presses.

One common cause of bleeding and smudging in flexo printing is poor ink or material quality.

It is possible for the material to leak and bleed if it does not have enough strength or flexibility to hold up to repeated printing pressure changes.

Additionally, if the ink does not wet the material evenly, clumps of ink will form along the seams, which will result in smudging.

Use high-quality material and match your press settings to the type of ink used on your material to reduce bleeding and smudging.

How to avoid bleeding and smudging issues?

Here are some tips for preventing bleeding and smudging:

1) Preheat your printer before starting the print job. This will help to reduce run-off and improve print quality.

2) Use quality material that is suited for flexo printing. Cheaper materials are often less durable and will cause more bleeding and smudging.

3) Verify your settings before starting the print job. Too much or too little Courier or other typeface used in your plate can cause excessive bleeding or smudging.

4) Be careful with text placement and avoid placing large areas of text close to the edge of the media, as this can lead to extensive bleeding and smudging.

5) Make sure your print heads are clean – accumulated dirt and dust can cause excessive bleeding and smudging. Clean your printer heads using a mild solution such as cleaning fluid or soap and water.

Is bleeding and smudging a serious issue in flexo printing?

Bleeding and smudging are serious issues in the flexo printing process. When bleeding occurs, the ink wand slips and bleeds through the material.

This causes spaces between the ink deposits on the material and can lead to smudging.

Achieving a high degree of accuracy and clarity is critical in flexo printing, so any mistakes can have a significant impact on the finished product.

Is bleeding / smudging in flexo printing just a print defect?

Bleeding / smudging is a common print defect that can occur during the printing process. This occurs when small droplets of ink escape from the print head and run across the print substrate, resulting in a blurry image. Bleeding / smudging is most commonly seen on photographic prints, but it can also affect text prints.

There are several things that you can do to minimise the chances of bleeding / smudging:

By use high-quality material, eliminate needless edges around your images, and use the correct printer settings.

FAQs:

What is pixel bleeding risk in flexo printing?

Pixel Bleeding is a risk that occurs when the image printed on a flexo-printing press is not perfectly aligned with the press mask.

When this happens, light and dark areas of the image mix, causing what’s called pixel bleeding, or RGB bleeding. Pixel bleeding can create unsightly distortions in your print.

To avoid this problem, always verify the alignment of your print before printing.