This article is part of the FLEXO FLAW FIXING series

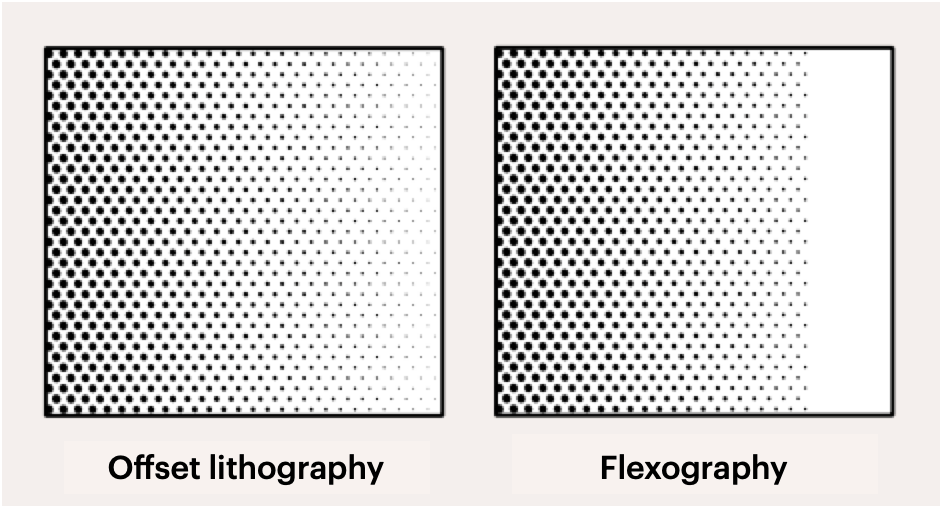

In the world of flexo printing, a clean and flawless print is not just an expectation, it is the standard to aim for. Dirty print in flexo printing has emerged as a notorious scourge that plagues printers, marring their output with isolated dots, unwanted bridged details and a general loss of the sharpness that defines high quality print work. In this article, we take an in-depth look at what dirty print is, how to identify it, and most importantly, how to effectively prevent and mitigate it.

Identifying Dirty Print in Flexo Printing

At its core, dirty print refers to the failure of vignette highlights to fade smoothly, resulting in a print that appears dirty or soiled. This print defect can be identified by visual cues such as excessive highlight gain or loss of fine type detail. It’s particularly problematic in areas where sharp images and clear typography are essential.

Root Causes and Solutions for Dirty Prints

Detecting dirty printing often requires a keen eye to spot the slightest inconsistencies, enabling early intervention and minimising waste.

Selection of Anilox Roll against Dot Dipping

Cause: An anilox roll selected without regard to LPI can introduce defects and facilitate dirty print through a phenomenon known as ‘dot dipping’.

Remedy: Select anilox rolls with an LPI of at least 5 times the print LPI to prevent dot dipping. In addition, banded anilox testing can help refine the perfect setup for cleanliness and clarity.

Adjustment of Doctor Blade for Accurate Inking

Cause: Incorrect adjustment of the doctor blade can lead to excessive ink transfer, resulting in a dirty print.

Remedy: Consistent evaluation and calibration of the doctor blade for precise pressure and angle ensures that only the required amount of ink is transferred to the plate, thus preventing dirty prints.

Choice of Ink Properties for Smooth Ink Transfer

Cause: Incorrectly adjusted ink viscosity and pH can wreak havoc, resulting in unclean prints.

Remedy: Carefully monitor and adjust ink properties, checking viscosity and pH levels frequently to maintain the stability and distribution required for perfect printing.

Precision in Platemaking for Graphic Fidelity

Cause: Platemaking errors, such as inappropriate relief depths, can compromise plate stability, resulting in a dirty print.

Remedy: Maintaining optimal back exposure times and thorough drying processes are critical to maintaining plate accuracy, especially for finer details and highlight areas.

Maintenance of Pressroom Conditions for Quality Control

Cause: Poorly maintained dryers and sub-optimal pressroom conditions can lead to ink drying defects, contributing to the problem of dirty print.

Remedy: Regular dryer maintenance and calibration, coupled with strict pressroom climate control, can prevent the environmental factors that lead to dirty print.

In Conclusion

In the quest for clean and accurate flexo printing, it is imperative to focus on detail-oriented process control. From choosing the right anilox rolls to maintaining a balanced pressroom environment, each factor plays a vital role in eliminating dirty prints. With technological advances and evolving methodologies continuing to push the boundaries, the future of flexo printing is resilient against the stubborn problem of dirty print, promising an era where every print is as flawless as it is impressive.