This blog was written by Sandra Kaiser from Flexo Consulting

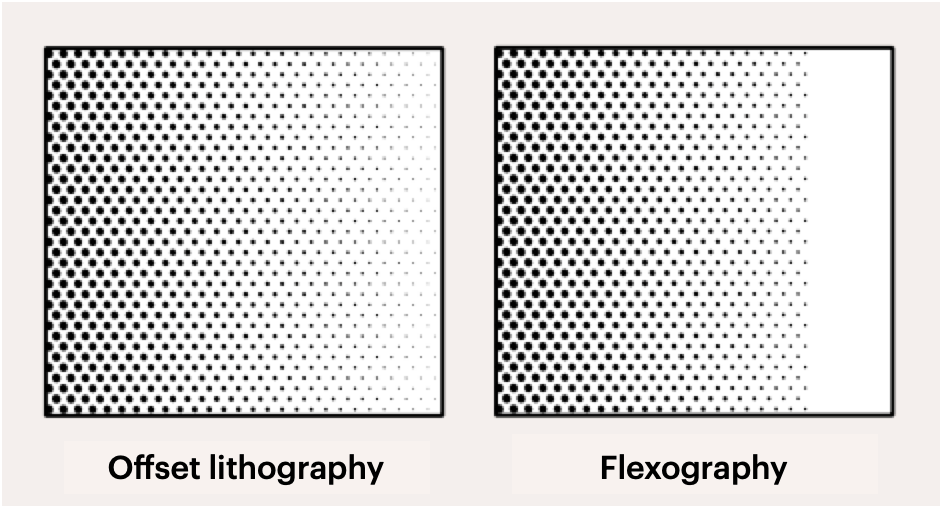

A wide range of materials can be printed using flexographic printing; technically speaking, anything could be printed using the letterpress process. The variety of materials ranges from paper to a wide variety of plastic films, aluminum foil and tissue materials for the hygiene sector, and even corrugated cardboard sheets. For reasons of economy, however, a wide variety of printing processes are used depending on the size of the run. This depends on the size of the printed product, the ink used, the printing plates and the type of machine. Differences between the printing unit variants lies in central cylinder presses, presses with a row design and stand design.

Flexible substrates are usually printed from the roll, dried and then rolled up again; this process is known as the roll-2-roll process. Rigid materials such as corrugated board sheets, on the other hand, can only be printed in a press with inline design. A feeder supplies the press with the separated sheets from a pallet, which are transported through the press via conveyor belts, with grippers or via vacuum suction knobs.

An exception is label printing, for which narrow-web presses are used that print in a row and combine different printing processes, such as flexographic and screen printing, for finishing.

What about the printing unit superstructure?

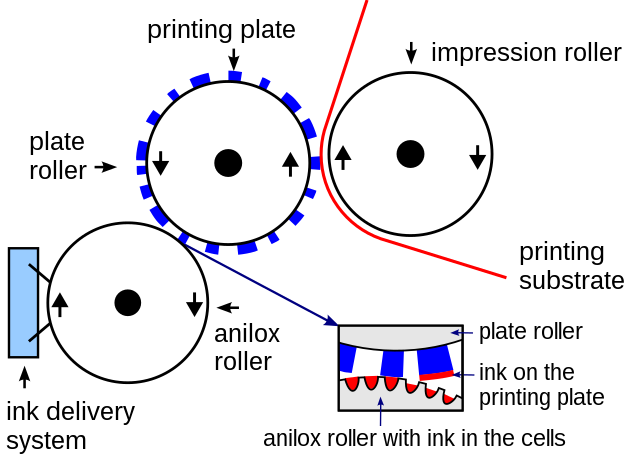

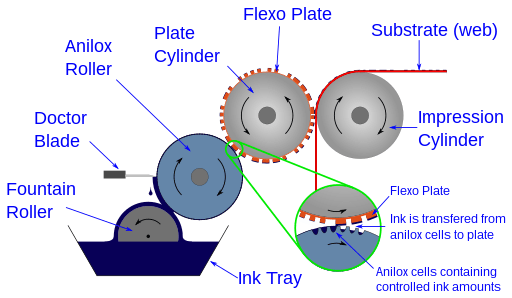

Today, only two superstructures are of general interest, the 3-roll or inking-roll printing unit as a squeegee system or with an open doctor blade system, and the 2-roll printing unit or doctor blade printing unit. In quality printing, however, the 2-roller doctor blade printing unit has clearly prevailed.

The dip roller printing unit is relatively easy to operate and adjust, and is mostly used for simple print jobs. The ink application is adjusted via the gap between the inking roller and the anilox roller. The printing form cylinder is driven by gear wheels. If a press of this type comes to a standstill, the plate cylinder must be lifted off the impression cylinder to prevent it from sticking together. This is usually done by spring force or hydraulics. In such a setup, it is important, among other things, that the anilox roller and the plate cylinder have the same circumferential speed, otherwise the plate (printing plate) would be destroyed.

In modern chamber doctor printing units with ink chamber squeegees, the doctor blade is usually adjusted pneumatically, and the contact pressure can be finely regulated. The doctor blade angle also plays an important role. The doctor blades are usually made of steel, with ceramic anilox rollers, doctor blades made of plastic are also used. In a chambered doctor blade system, doctor blades with a ground phase have become established. When installing new doctor blades, cut-resistant gloves must be worn. The doctor blades must be handled with care, as damage can lead to destruction of the anilox roll.