What is varnish coating in flexo printing?

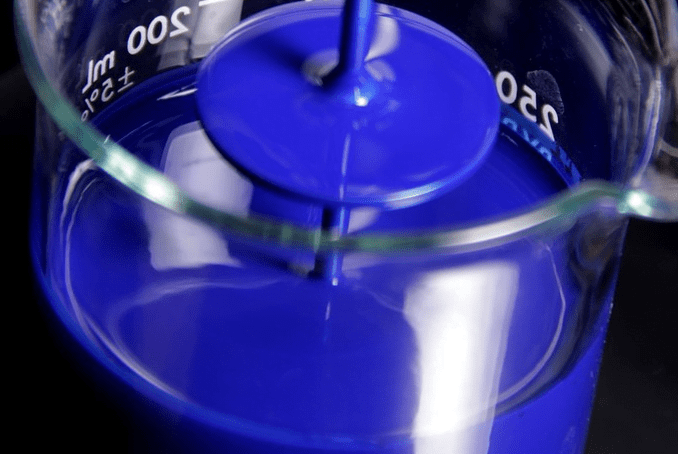

The process of varnish coating in flexo printing involves applying a transparent layer of silicon over a printed area. In order to highlight a specific area of a design – such as a logo – it is applied to the entire surface of the printed item. It gives the appearance of a glossy or matte luxurious finish.

Varnish is made from a silicone polymer that is highly resistant to solvents and water.

A flexo coating system is most commonly used to apply a clear topcoat. Flexo coating systems consist of sprayable or roll-on paints that are flexible as well as formulated for the specific application. It has been coated onto a substrate and cured to make it impervious to moisture and abrasion. There are two types of coating systems: one is a water-based varnish, and the other is an oil-based varnish.

Applying Method

A varnish is a coating that can be printed on a press like ink is. You can print the varnish either as a flood, which covers the entire print, or a spot varnish, which allows you to varnish only specific text, images or graphics on your printed piece. If you choose a spot varnish, a plate will be required to print, and artwork designating the areas you want the spot varnish to cover needs to be provided to your service provider.

Types of Varnish

Varnishes can be either gloss, satin or matte and they all provide extra protection for your printed piece. If you have a print project that will be heavily handled then using a varnish will keep the piece looking nice and not get scratched as easily. An added bonus to using a varnish, is the ability to tint the varnish with a PMS color.

Varnishes can possibly yellow over time on areas that are not printed. If a varnish is covering the print, the yellowing will not be noticeable, only when it is directly on unprinted paper will it show.

Gloss Varnish

Gloss varnish works well on glossy surfaces and ads shine where it’s applied.

Highlight areas of your print media piece with a spot gloss varnish to give it a pop. Adding it to your piece gives your images and colors more depth and its reflective qualities give it a glare, enticing people to look at the areas where it was applied. To create a good contrast between your glosses varnished areas and the unvarnished areas, apply a satin or matte varnish. It will prevent scuffing and rubbing off of surfaces with heavy coverage if the piece is given an overall gloss varnish.

Matte Varnish

It gives your printed piece a less glossy appearance. The matte varnish will also protect your project from fingerprints, but will scuff more easily than the gloss varnish. A matte varnish will soften colors and images, but there won’t be any glare, so text will be easier to read. Matte varnish can also be applied to coated papers to create a nice contrast. Uncoated papers will only get extra protection from scratches and scuffs if you print matte or gloss varnish on them. When printed on gloss paper, they will have more shine.

Satin Varnish

Stain varnish is created by mixing gloss and matte varnishes together. Providing a little shine and protecting your project, this varnish is excellent.

Read next about what is a turn bar press on a web press