Flexographic printing on blister packaging can achieve high-resolution printing results, but care must be taken not to damage the seal’s integrity so that the contents are not compromised by outside elements. Consider the following troubleshooting tips for resolving blister packaging printing issues in flexo printing.

4 Common Difficulties Manufacturers Encounter When Printing on Blister Packaging in flexo printing?

Products must contain the necessary printing and labeling information by the legislation mandated by the relevant governing bodies, but manufacturers may face difficulties when printing onto blister packaging. Let’s look at some of the four common issues:

- Print quality: All prints must be machine-readable regardless of their size or substrate. Because foil is commonly used in blister packaging, the technology must be able to print at a high resolution to meet industry standards. Prints that are not crisp, clean, or clear will fail quality control checks, resulting in costly downtime, product waste, and increased ink consumption.

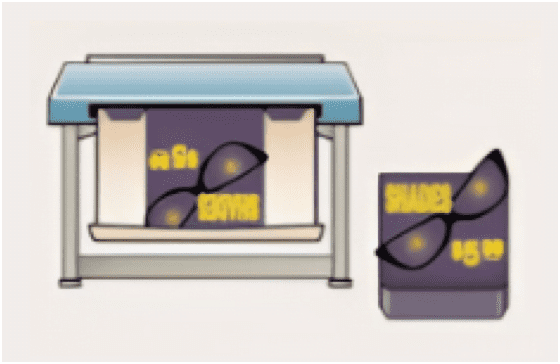

- Product handling: Products must be presented to the printhead in a consistent and controlled format for printing onto the correct areas.

- Packaging material types: Blister packaging is used for a wide range of applications that may necessitate the use of specific packaging materials such as foil or Tyvek®. Manufacturers must choose an appropriate ink that is suitable for fast adhesion based on the material. Fast drying times are required for products that come into contact with other materials and must not smudge after printing.

- Production line speed: The volume of throughput is high in the pharmaceutical, electronic, and toy industries. Manufacturers may face difficulties maintaining accuracy, efficiency, quality control, and avoiding downtime in the absence of a dependable solution. Manual processes can take a long time when switching to a different product, and thus different coding messaging.

Can the Flexographic Printing Process Be Used to Produce Blister Packs?

The blister pack industry benefits greatly from flexographic printing. Flexo printing is effective on a wide range of substrates, which accommodate the various materials used in blister packs. One thing to keep in mind is that printing inks should be free of ingredients that could interfere with the adhesion process and may need to be heat-tolerant.

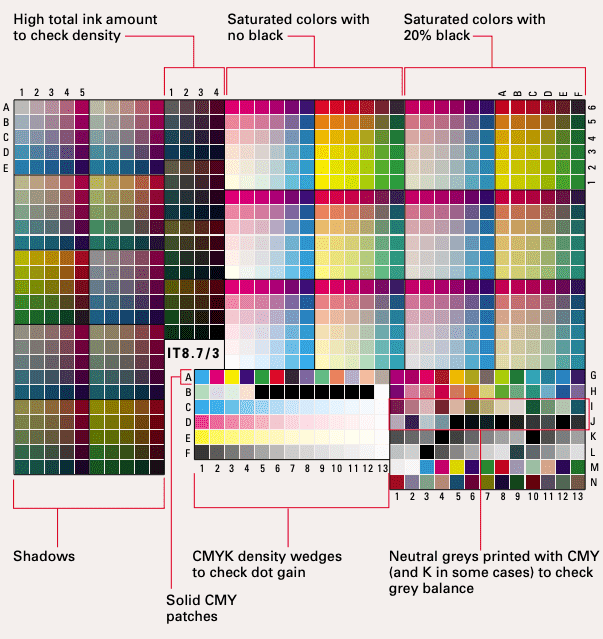

Troubleshooting Flexo Printing on Blister Packaging’s Top 4 Culprits

Here are a few of the most likely suspects for blister packaging defects.

- Ink

- Image carrier

- Ink PH

- Viscosity

Each element has its own set of considerations for how it can cause a print defect.

1. Ink:

Inks used for printing on blister packaging must be compatible with the backing material and free of ingredients that could interfere with the adhesion process. Depending on the adhesive used, they may need to be heat resistant. Furthermore, contaminated ink can cause hickeys or foreign particles on your finished product.

2. Image Carrier:

Before each print run, inspect the image carrier and ensure that it is properly maintained. Dirty prints, uneven ink transfer, spotty printing, streaking, washboard effects, and image bleeding can result from dirty, soft, worn, or lose sleeves, cylinders, or plates.

3. Ink PH:

If the image carriers are in good condition but you are still experiencing issues, the pH of the ink could be the cause. Cardboard, foil, or plastic could be used as the backing. Different materials may necessitate inks with pH levels that dry slower or faster, allowing them to adhere to the substrate.

4. Viscosity:

Your blister packaging print runs may experience foaming, abrasion, spotty ink deposits, or uneven appearance if your viscosity is too low. If you set it too high, you may get smeared ink, uneven color, darker colors than expected, halos, and fisheyes.

How to Resolve Common Blister Packaging Printing Issues in flexo printing

The adhesive build-up, thermal expansion, clean-up issues, and other mishaps can all be problems in blister packaging. Here are some suggestions for how to improve the process:

- Press maintenance: Always keep presses in good working order, monitor printing pressure, and reduce wobbling.

- Pressure: Make a kissing motion and adjust the pressure accordingly.

- Gears: Check the condition, lubrication, and cleaning of gears regularly.

- Contamination: Keep image carriers in good condition and look for dried ink on the anilox.

- Ink: Use the appropriate ink for the plastic, backing, and adhesive.

- Image carrier: Avoid using harsh solvents or cleaning agents on the image carrier.

- Distribution: When using adhesives, the silicone elastomer is likely the best material option, regardless of whether the image carrier is a sleeve, cylinder, or plate.

- Anilox: Select an anilox with cells that can hold and transfer ink at the appropriate rate.

- Drying: Don’t be so focused on productivity that you neglect to allow adequate drying time.

Is the Flexo Issue Still Unresolved?

Flexo printing on blister packaging necessitates a careful balance of several factors. All components must be exactly correct for a print run to turn out exactly as expected.

Image credit: iStock

Read next about Flexo printing on film substrates troubleshooting