Category: Flexo Basics

Wash-out solvents for flexo plates

by Info Anyflexo | Aug 1, 2024 | Flexo Basics, Flexo Tech, Flexography, Plate Making, Printing Plates | 0

What is the need of solvents for flexographic printing plates? Flexography uses „standing“...

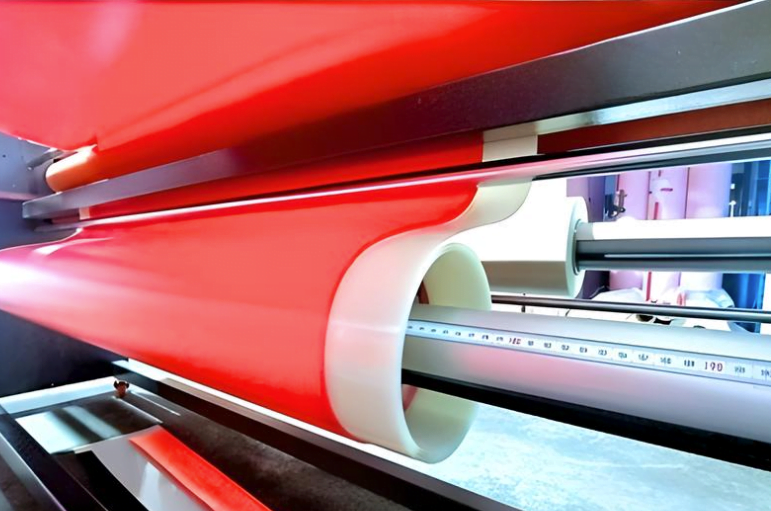

Read MoreDouble Adhesive Tapes for Flexo Printing

by Mario Busshoff | Apr 10, 2024 | Flexo Basics, Mounting Tapes | 0

What is the function of the adhesive layer? In flexo printing, the cross section up of double...

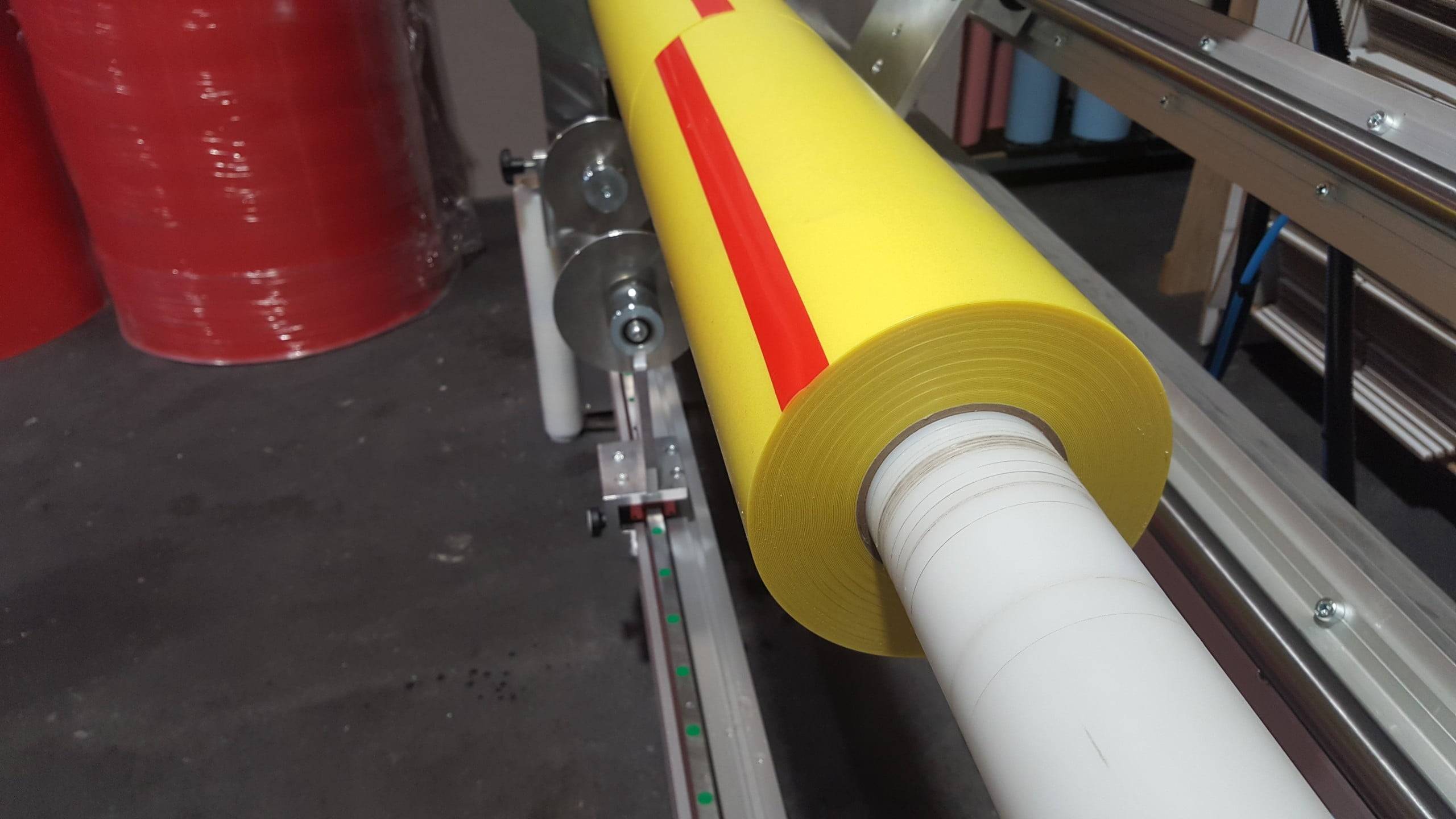

Read MoreMounting Tapes for Flexo Printing

by Mario Busshoff | Feb 28, 2024 | Flexo Basics, Mounting Tapes | 0

What is the general purpose of mounting tapes for flexo printing? Well – it needs to stick!...

Read MoreSecret to Better Printing: Ink Surface Tension

by Any flexo | Mar 27, 2023 | Flexo Basics, Printing | 0

If you work in flexo printing, you understand the intricate details involved in achieving flawless...

Read MoreUnderstanding Surface Tension and Surface Energy Related to Wettability

by Any flexo | Mar 22, 2023 | Flexo Basics, Printing | 0

Achieving good adhesion and print quality is essential for any print job. It starts with ensuring...

Read MoreHow to Choose the Right Flexo Printing Press

by Any flexo | Mar 20, 2023 | Flexo Basics, Printing Presses | 0

Buying a flexo press is a lot like buying a car. Finding the right balance between safety,...

Read MoreFix Common Challenges in Foil Embossing

by Any flexo | Feb 21, 2023 | Flexo Basics, Printing | 0

In today’s competitive market, smart packaging and effective branding have become essential...

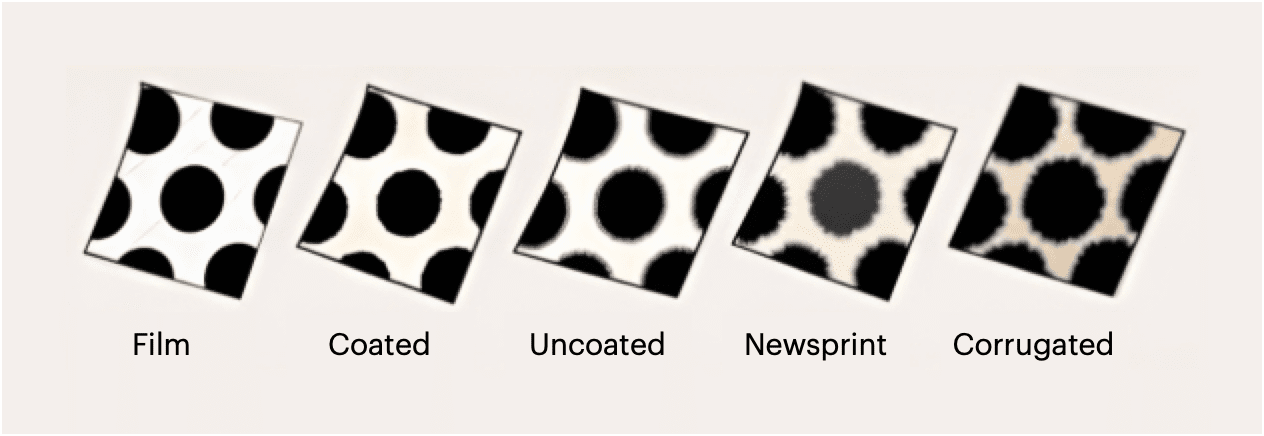

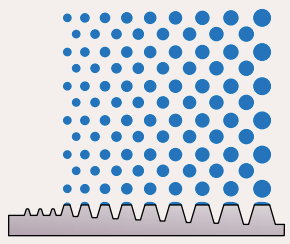

Read MoreMastering Flat Top Dots in Flexo Printing

by Any flexo | Feb 16, 2023 | Flexo Basics, Printing Plates | 0

In the realm of flexo printing, meticulous attention to detail can yield significant outcomes. One...

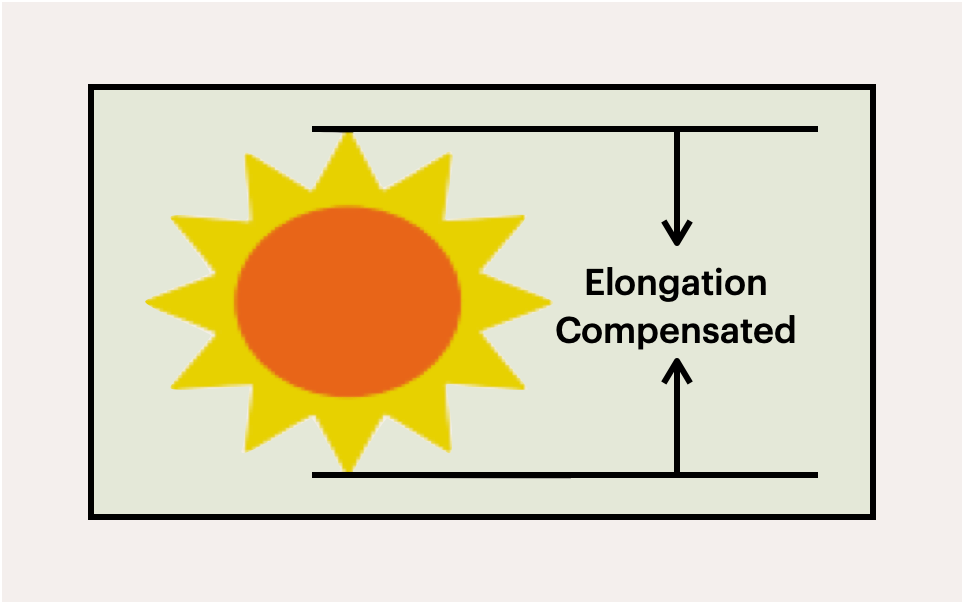

Read MoreElongation and Distortion in Flexo Printing

by Any flexo | Feb 10, 2023 | Flexo Basics, Plate Making | 0

Flexo printing, commonly used for packaging and labels, requires precision. Accurate platemaking...

Read MoreExploring the Superior Benefits of Elastomer Blends Compared to Photopolymers

by Any flexo | Feb 1, 2023 | Flexo Basics, Printing Plates | 0

It’s no secret that large-scale printing operations have long been popular. But would it...

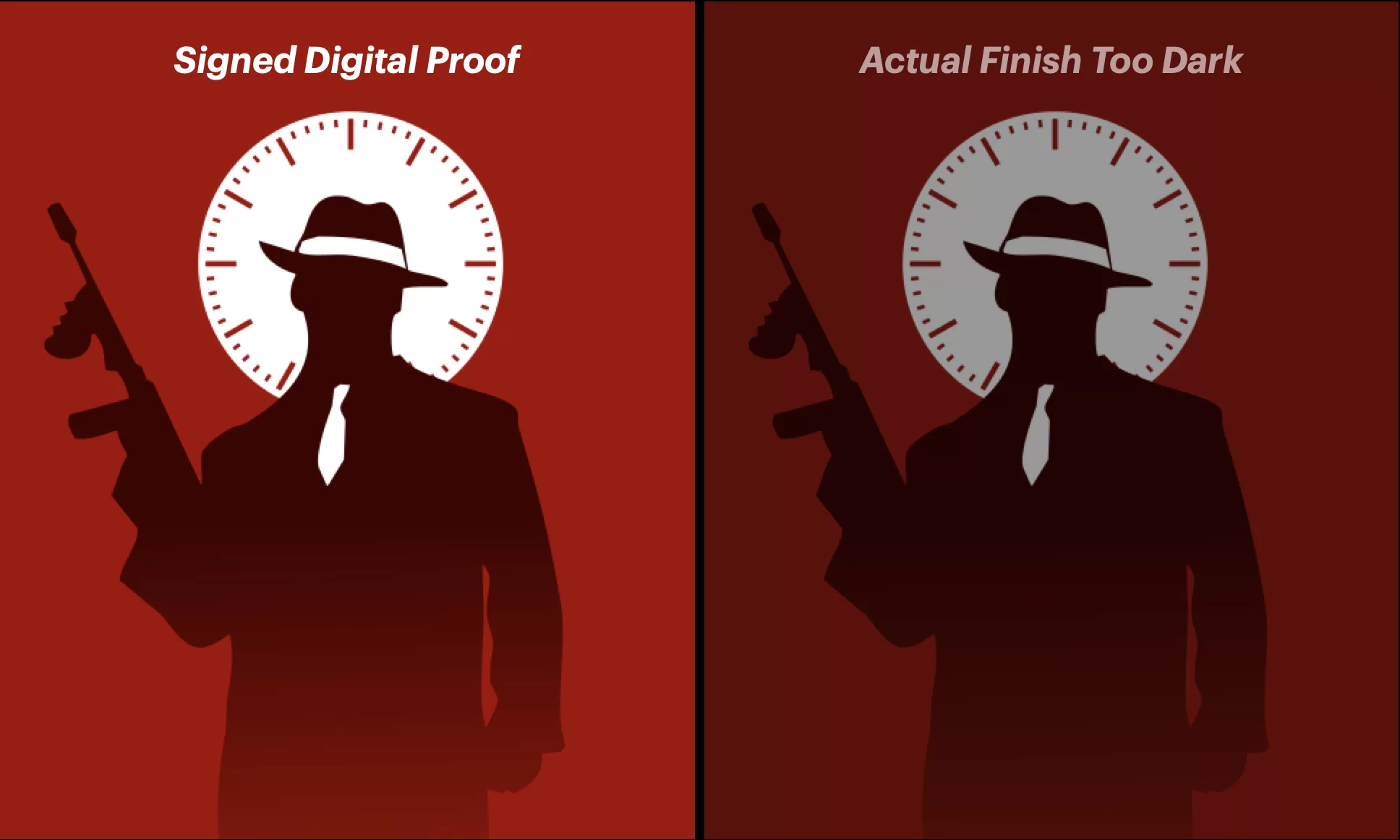

Read MoreFingerPrint and Proofing Flexography

by Any flexo | Jan 6, 2023 | Flexo Basics, Prepress | 0

What is Flexo print colour management? Flexo print colour management manages every step in...

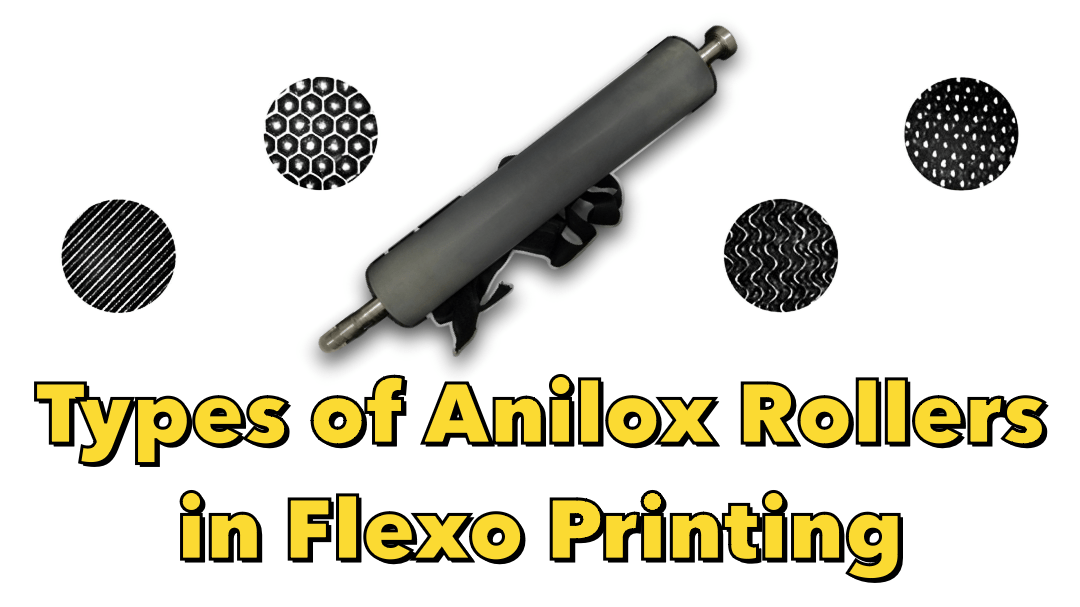

Read MoreAnilox Rollers in Flexo Printing

by Any flexo | Jan 3, 2023 | Cylinders, Featured Articles, Flexo Basics | 0

What Constitutes an Anilox Roller in Flexo? An anilox roller, a critical component in flexographic...

Read More

Recent Blogs

- Densitometers in Flexographic Printing: Your Ultimate Guide to Ink Density Control

- Multi-Deck Designs in Flexographic Printing: Unlocking High-Efficiency Print Power

- Space-Saving Layouts in Flexographic Printing: Smart Design for Leaner, Smarter Pressrooms

- Multiple Color Units in Flexographic Printing: The Key to Vibrant, Complex, and Consistent Packaging

- Satellite Printing Stations in Flexographic Printing: A Central Impression Solution for Speed, Precision, and Performance

Categories

- All Blogs (171)

- Flexo Basics (53)

- Flexo in Use (24)

- Flexo Tech (26)

- Hands-on Time (19)

- Printing Flaws (32)

- Component-based (45)

- Cleaning Supplies (1)

- Cylinders (13)

- Inking Units (3)

- Inks & Varnishes (8)

- Mounting Tapes (4)

- Printing Plates (9)

- Printing Presses (7)

- Equipment & Machinery (36)

- Fact-based (36)

- Contrasting Views (9)

- Flexography (11)

- Market Application (11)

- Sustainability (5)

- Featured Articles (4)

- Process-based (42)

- Plate Making (10)

- Plate Mounting (3)

- Postpress (4)

- Prepress (14)

- Printing (11)

- Video (3)