Category: Flexo Tech

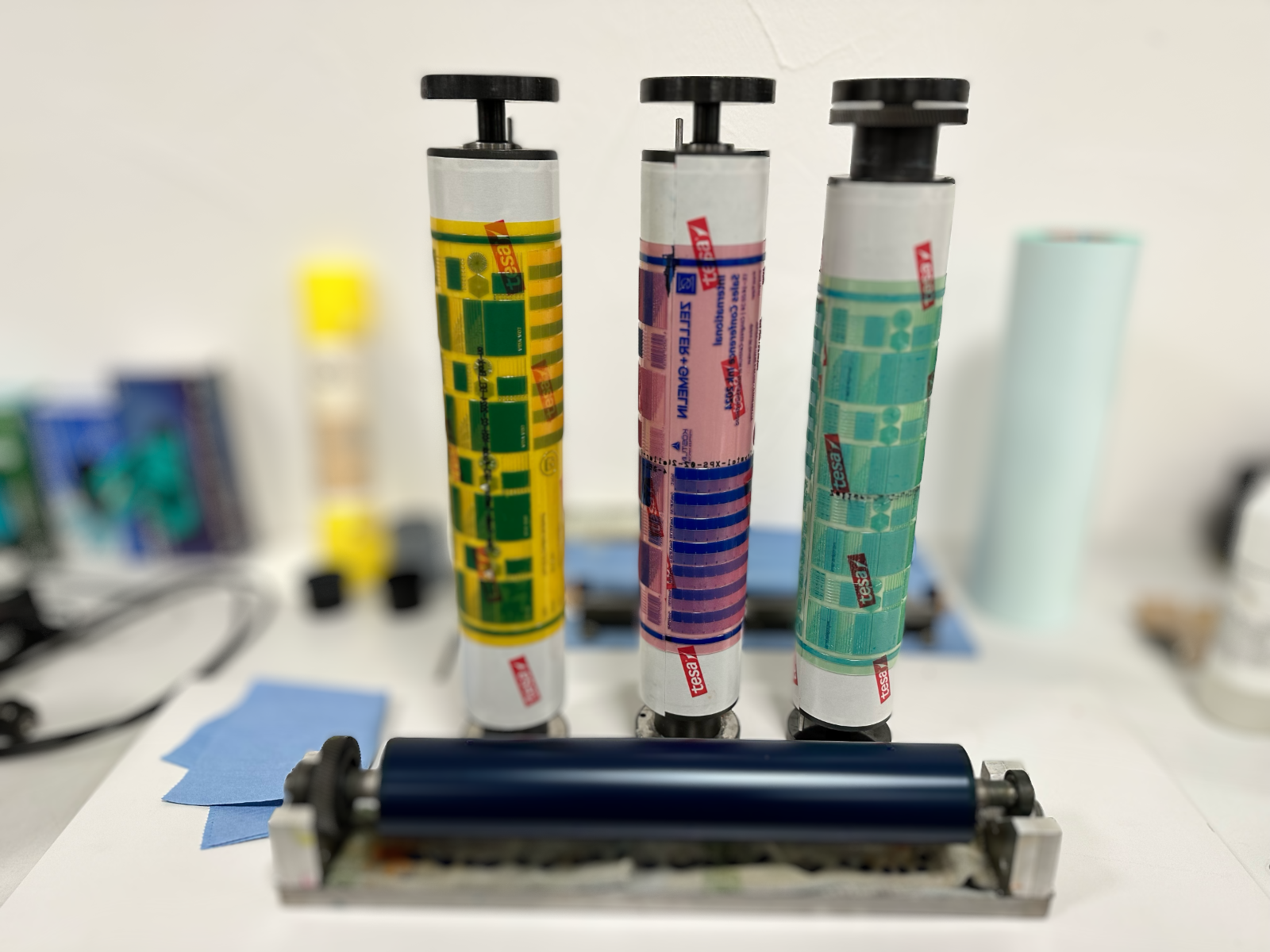

Compressible Backing in Corrugated Post-Print

Posted by Any flexo | Jun 25, 2024 | Flexo Tech, Mounting Tapes | 0

Flat Top Dot Plates with Surface Screening in Flex...

Posted by Info Anyflexo | May 8, 2024 | Flexo Tech, Printing Plates | 0

Electric Heating Roller, Not Just For The Laminati...

Posted by Info Anyflexo | Apr 15, 2024 | Cylinders, Flexo Tech | 0

Wash-out solvents for flexo plates

by Info Anyflexo | Aug 1, 2024 | Flexo Basics, Flexo Tech, Flexography, Plate Making, Printing Plates | 0

What is the need of solvents for flexographic printing plates? Flexography uses „standing“...

Read MoreCompressible Backing in Corrugated Post-Print

by Any flexo | Jun 25, 2024 | Flexo Tech, Mounting Tapes | 0

Why use cushioning materials in flexo? Corrugated box printing mainly adopts flexo printing as it...

Read MoreFlat Top Dot Plates with Surface Screening in Flexo Printing

by Info Anyflexo | May 8, 2024 | Flexo Tech, Printing Plates | 0

Recent trends and challenges in the flexo printing industry have led to a shift from digital round...

Read MoreElectric Heating Roller, Not Just For The Lamination Process

by Info Anyflexo | Apr 15, 2024 | Cylinders, Flexo Tech | 0

What are heating rollers used for? Why do you need heating rollers and what are they? A heating...

Read MoreWinding Cores in Foil Processing: Aluminium vs. Cardboard Tubes

by Fiete | Feb 5, 2024 | Cylinders, Flexo Tech | 0

What does the choice of an optimal winding core contribute to the result of a print job? First of...

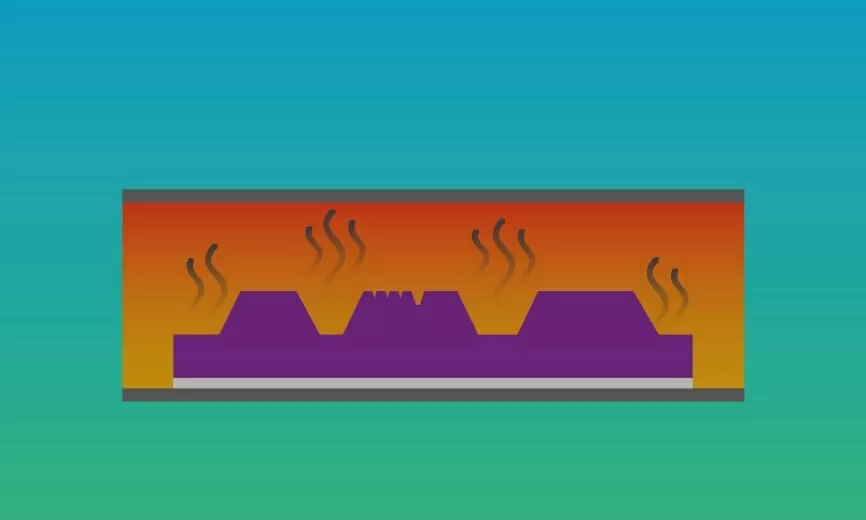

Read MoreDrying in Flexo Platemaking

by Any flexo | Jan 24, 2023 | Flexo Tech, Plate Making | 0

This blog was written and submitted to us by Torben Wendland The drying step in flexo...

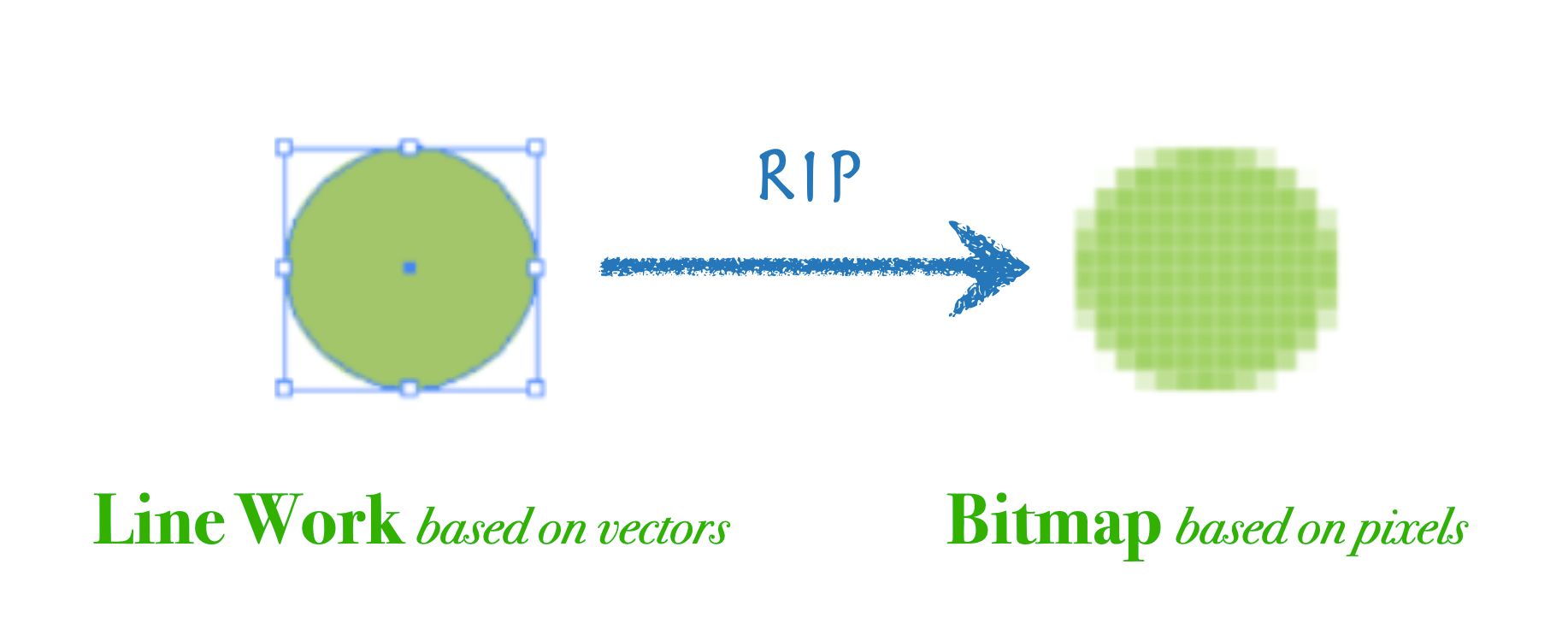

Read MoreRIP and Software Solutions in Flexo Printing – Part 2

by Any flexo | Jan 13, 2023 | Flexo Tech, Prepress | 0

As we enter the digital age, the printing industry has undergone a remarkable transformation. The...

Read MoreRIP and Software Solutions in Flexo Printing – Part 1

by Any flexo | Jan 11, 2023 | Flexo Tech, Prepress | 0

Printing has evolved into a complex interplay of technology and craftsmanship, with the Raster...

Read MoreFlexoPrint Mobile Application

by Any flexo | Jan 10, 2023 | Flexo Tech, Prepress | 0

FlexoPrint is a special, useful and free mobile application. Excellent for prepress personnel...

Read MoreWashout Processing in Flexo Platemaking

by Any flexo | Aug 5, 2022 | Flexo Tech, Plate Making | 0

This blog was written and submitted to us by Torben Wendland During photopolymer washout...

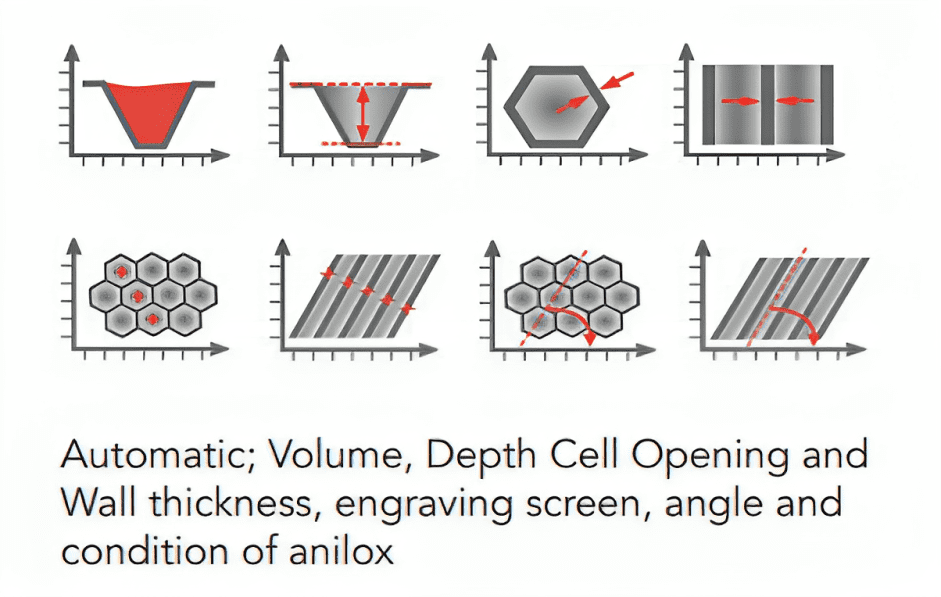

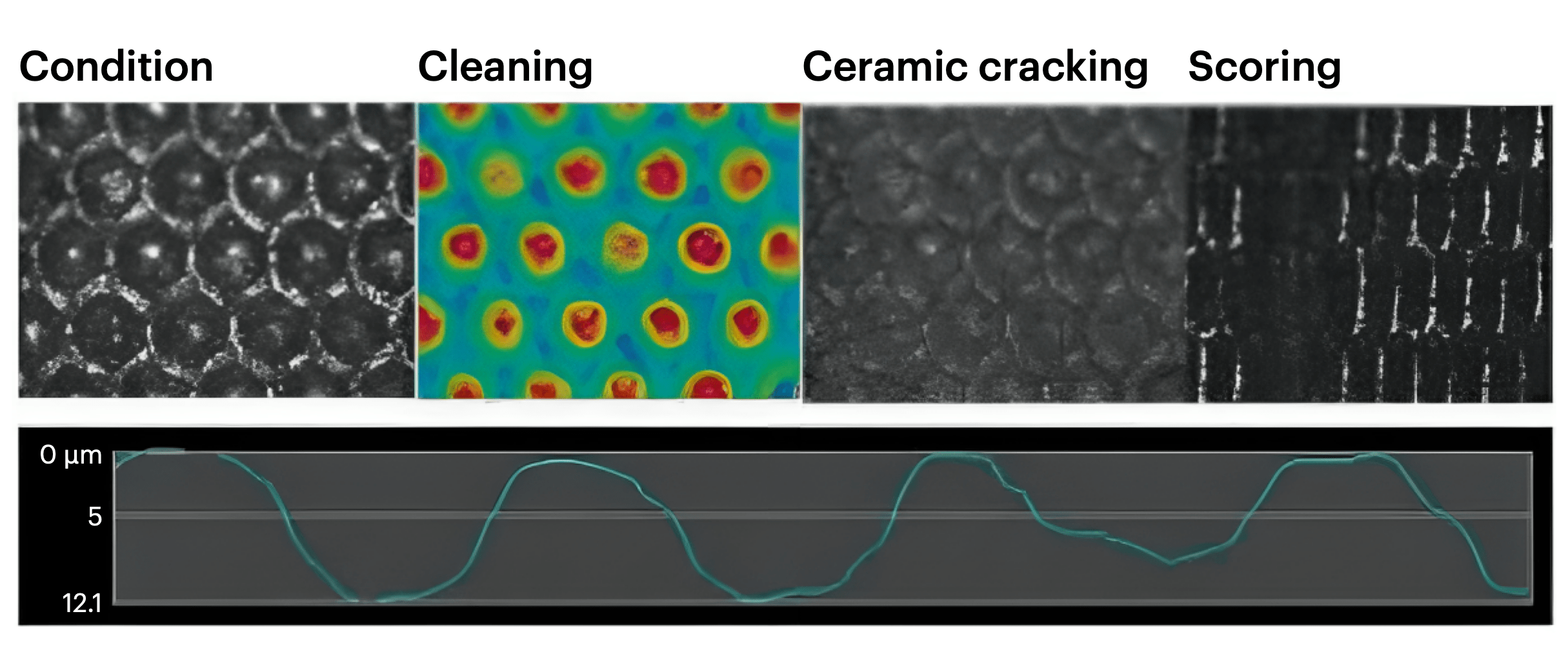

Read MoreHow to Inspect Anilox Rollers Part 3 – Best Practice

by Any flexo | Jul 4, 2022 | Cylinders, Flexo Tech | 0

The article was prepared and submitted to us by Troika Systems Ltd. In the previous part, we...

Read MoreHow to Inspect Anilox Rollers Part 2 – Device & Programme

by Any flexo | Jul 4, 2022 | Cylinders, Flexo Tech | 0

The article was prepared and submitted to us by Troika Systems Ltd. In the previous part, we...

Read More

Recent Blogs

- Densitometers in Flexographic Printing: Your Ultimate Guide to Ink Density Control

- Multi-Deck Designs in Flexographic Printing: Unlocking High-Efficiency Print Power

- Space-Saving Layouts in Flexographic Printing: Smart Design for Leaner, Smarter Pressrooms

- Multiple Color Units in Flexographic Printing: The Key to Vibrant, Complex, and Consistent Packaging

- Satellite Printing Stations in Flexographic Printing: A Central Impression Solution for Speed, Precision, and Performance

Categories

- All Blogs (171)

- Flexo Basics (53)

- Flexo in Use (24)

- Flexo Tech (26)

- Hands-on Time (19)

- Printing Flaws (32)

- Component-based (45)

- Cleaning Supplies (1)

- Cylinders (13)

- Inking Units (3)

- Inks & Varnishes (8)

- Mounting Tapes (4)

- Printing Plates (9)

- Printing Presses (7)

- Equipment & Machinery (36)

- Fact-based (36)

- Contrasting Views (9)

- Flexography (11)

- Market Application (11)

- Sustainability (5)

- Featured Articles (4)

- Process-based (42)

- Plate Making (10)

- Plate Mounting (3)

- Postpress (4)

- Prepress (14)

- Printing (11)

- Video (3)