In the vibrant world of flexographic printing, color isn’t just visual—it’s critical. It defines a brand’s identity, evokes emotion, and ultimately shapes the consumer’s perception. And yet, among all the variables on a flexo press, color remains one of the most complex to manage.

From ink formulation to press speed, every factor can influence color output. That’s why color measurement—not just color “matching” by eye—is the cornerstone of quality assurance in modern flexo environments.

This article takes you deep into the practical science of color measurement in flexographic printing, offering expert techniques and insights that ensure accuracy, consistency, and confidence from job start to finish.

Why Color Measurement Matters in Flexography

Let’s face it: eyeballing color isn’t enough anymore. While the human eye is excellent at identifying major mismatches, subtle inconsistencies can still slip through unnoticed. For brand owners, even a ΔE (Delta E) difference of 2 can be unacceptable.

In flexo, color consistency is a contract. Whether you’re printing for food packaging, labels, or pharmaceutical boxes, clients expect precision. Failing to measure color accurately can lead to:

- Costly reprints

- Rejected shipments

- Damage to brand reputation

- Longer approval cycles

Color measurement isn’t just a QA step—it’s a competitive edge.

Understanding the Fundamentals: What Is Color Measurement?

Color measurement is the process of quantifying color using scientific methods. It involves using instruments to measure how light interacts with an object (in our case, printed substrate), and calculating numeric values that represent the color.

The two most common metrics used in flexo printing are:

- Density: How much light is absorbed by the ink. Ideal for process control.

- ΔE (Delta E): A numerical value that describes the difference between two colors. Ideal for color matching.

Most color control systems in flexography utilize spectrophotometers, densitometers, or color scanners to capture and analyze these values.

Device Types for Measuring Color in Flexo

Handheld Densitometers

Used for spot-checking solid ink densities, dot gain, and trapping on pull sheets. Simple and fast, but not ideal for detailed colorimetric analysis.

Spectrophotometers

The gold standard in color measurement. They can measure Lab* values and compute ΔE. Available in handheld and inline versions, they’re essential for verifying brand colors and calibrating profiles.

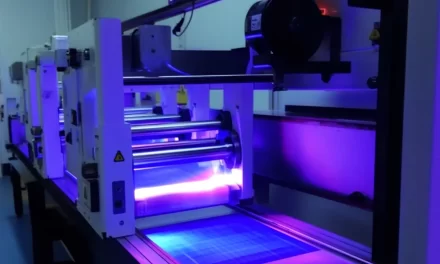

Inline Color Measurement Systems

Mounted on the press, these systems continuously monitor color throughout the print run. They eliminate guesswork, reduce operator fatigue, and trigger alerts when deviations occur.

Popular Tools: X-Rite eXact, Techkon SpectroDens, AVT Spectralinks, KBA QualiTronic.

7 Smart Techniques for Accurate Color Measurement in Flexography

Calibrate Before Every Shift

Before any color measurement is taken, your devices must be calibrated to a known white reference tile. Dirty or uncalibrated devices will yield misleading results, giving you false positives or negatives.

Tip: Set a daily or shift-based calibration schedule. Use automatic reminders to avoid skipping.

Use Target Profiles and Color Standards

Every job should begin with a target profile or color specification. This could be a brand Pantone value, a LAB coordinate, or a custom swatch provided by the client.

Convert all color targets into measurable formats using ICC profiles. Input them into your spectro system for accurate comparison.

Measure on the Correct Substrate

The same ink behaves differently on different substrates. That’s why measuring color on the actual production material is critical.

Tip: Always perform color measurement on live substrate (not on generic paper or film). Optical brighteners, opacity, and coating affect final appearance.

Account for Dry-Back Effects

Water- and solvent-based inks in flexo dry quickly. But here’s the kicker—wet ink often appears more saturated than its dry version.

What looks perfect during the press check might dry to a duller hue. To avoid surprises:

- Wait for prints to fully dry before measuring.

- Use test sheets or proofers that simulate final dryback.

Track ΔE Consistently

ΔE is the industry-standard metric for color difference. Lower values indicate better matches.

| ΔE Value | Color Match Quality |

|---|---|

| 0 – 1 | Perfect match |

| 1 – 2 | Barely perceptible |

| 2 – 3 | Acceptable (most jobs) |

| 3 – 5 | Noticeable difference |

| >5 | Unacceptable |

Best practice: Keep ΔE under 2 for brand colors, and under 3 for CMYK builds.

Measure Multiple Points Across the Web

Ink can behave inconsistently across the width of the substrate. That’s why measuring only one spot isn’t enough.

Instead:

- Sample across the web (left, center, right)

- Average the values or identify trends

- Adjust ink flow or doctor blade pressure based on results

Some inline spectro systems automate this completely, saving time and increasing accuracy.

Train Operators to Interpret Readings

Measuring is one thing—understanding what those numbers mean is another. Your team needs to know:

- What LAB and ΔE values represent

- How ink viscosity or anilox volume affects density

- When to adjust press settings vs. stopping the job

Provide regular training and create cheat sheets with acceptable values for common jobs.

Color Measurement in Digital vs Flexo

While digital printing often boasts tighter color control due to its software-driven nature, flexographic printing can match or even exceed those standards—with the right equipment and protocols.

Color measurement levels the playing field. Hybrid workflows that combine flexo with digital tools (like digital proofs and RIP profiles) further enhance consistency.

Avoid These Common Color Measurement Mistakes

- Measuring while ink is still wet

- Skipping calibration routines

- Using damaged or smudged target patches

- Not compensating for press warm-up color drift

- Comparing against the wrong target (e.g., on matte vs gloss stock)

A little discipline goes a long way. Build these checks into your SOPs (Standard Operating Procedures) to ensure compliance.

Why Color Management = Profitability

Let’s not sugarcoat it—every color issue costs money.

A rejected run due to off-color packaging could result in:

- Wasted ink and substrate

- Press downtime

- Expedited reprints

- Lost client trust

Color measurement is one of the few investments that pays for itself almost immediately. It’s the bridge between what your clients expect and what your press delivers.

Tools and Software to Help

| Tool | Purpose |

|---|---|

| X-Rite ColorCert | Job setup and color scoring |

| Esko Equinox | Extended gamut color separation |

| Techkon SpectroConnect | Cloud-connected device tracking |

| PantoneLIVE | Digital brand color libraries |

| GMG OpenColor | Proofing and color conversion |

Pair these with your MIS/ERP systems for full-color reporting from proof to press.

Conclusion: Color Measurement Is a Mindset, Not a Machine

In flexographic printing, success doesn’t come from luck—it comes from control. And color control starts with measurement.

By investing in reliable tools, training your staff, and building workflows around precise color data, you can deliver brilliant, consistent color every time—on every job, for every customer.

Because in flexo, color is currency. And with the right measurement strategy, you can print money every single day.