Advancements in corrugated package printing have brought about remarkable transformations in the packaging industry. Traditionally, corrugated packing materials, while durable during transit, were difficult to print on due to their absorbent nature and susceptibility to damage from rough printing processes. As a result, businesses often used shipping and display boxes with uninspiring, low-resolution imagery. However, innovations in technology and enhanced printing techniques have enabled a leap in the quality of flexo printing in corrugated packaging, allowing brands to improve product visibility and strengthen brand recognition.

Prominences of Flexo Printing in Corrugated Packaging

Flexography stands out as particularly suited for high-volume production in the corrugated packaging sector. This method involves using flexible photopolymer printing plates mounted on rotating cylinders within a web press. With plates featuring a slightly raised image, they can rotate at high speeds to directly transfer ink onto the corrugated cardboard substrate. Flexo is eminent for its flexibility in handling diverse ink types – such as water-based, solvent-based, and UV-curable inks – and its capacity to produce robust prints that can withstand various environmental conditions during transit.

Unlike in the past, where flexo struggled to match the quality of other printing techniques, technological progress has now enabled it to achieve high-resolution and detailed graphic outputs. This closure of the quality gap is particularly significant in a market where both visual appeal and production efficiency are paramount.

Moreover, the speed at which flexographic presses operate makes this a cost-effective option for producing large quantities of packaging. It translates to lower per-unit costs without compromising on the final print’s durability. As brands increasingly seek environmentally friendly packaging solutions, flexo’s compatibility with water-based inks presents an attractive characteristic, further consolidating its position as a preferred printing method for corrugated packaging.

Comparison with Other Common Techniques

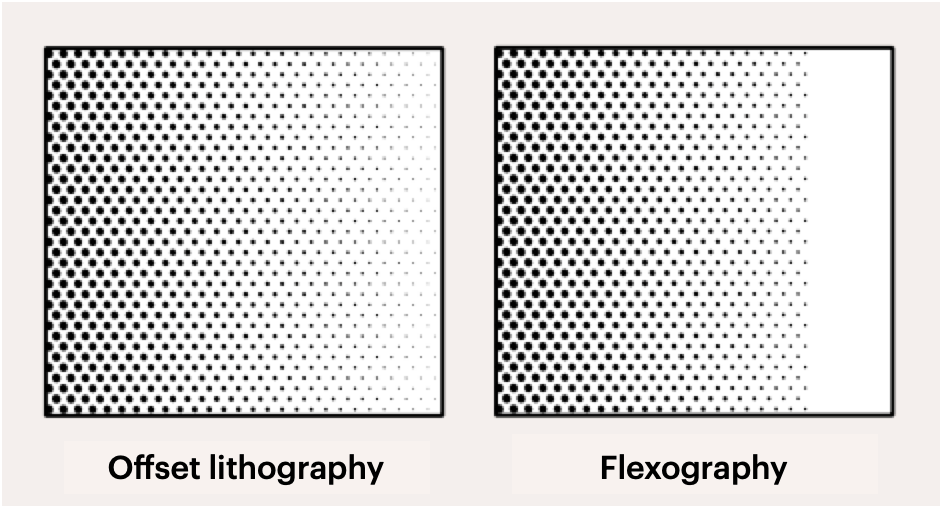

However, when comparing different printing practices for corrugated packaging – namely, flexographic, lithographic, screen, and digital printing – several distinctions arise. Each method has its advantages and trade-offs depending on the project requirements.

Lithographic Printing

also known as offset printing, is known for its high-quality image reproduction and is suitable for detailed graphic work on corrugated materials. While it delivers superior print clarity and resolution compared to flexography, it can be more costly and less adaptable for printing directly onto corrugated substrates, often requiring the litho-laminating process, wherein a printed paper is mounted onto the corrugated board.

Screen Printing

on corrugated materials is another option that offers high ink coverage and the ability to print on various textures and substrates. Its applications to corrugated materials are typically for small runs with specific, often tactile, quality demands. Although it provides a rich, dense colour and allows for unique effects, it is less efficient for large-scale production due to slower speeds and higher costs per unit.

Digital Printing

meanwhile, is the newest entrant into the corrugated packaging printing scene. It shines in providing on-demand, customisable printing options with low setup times, making it ideal for short runs and high personalisation. The quality is comparable to litho in many cases, but the speed and cost-effectiveness fall behind when it comes to long production runs, where flexography still holds an advantage.

Whereas all these printing methods serve their purpose in the production of corrugated packages, flexography remains a robust, versatile choice, particularly for high volume, cost-effective production runs with a reasonable quality expectation. Its ability to adapt to fast-paced manufacturing requirements while producing durable, high-quality prints makes flexo an enduring and popular choice in the packaging industry.

Summary

When choosing a printing technology for corrugated packaging, manufacturers weigh aspects such as production speed, print quality, versatility, cost, and the quantity needed. Flexography often emerges as the best option for most high-volume needs, while lithography is preferred for high-quality image demands, screen for special applications, and digital for small runs requiring customisation.