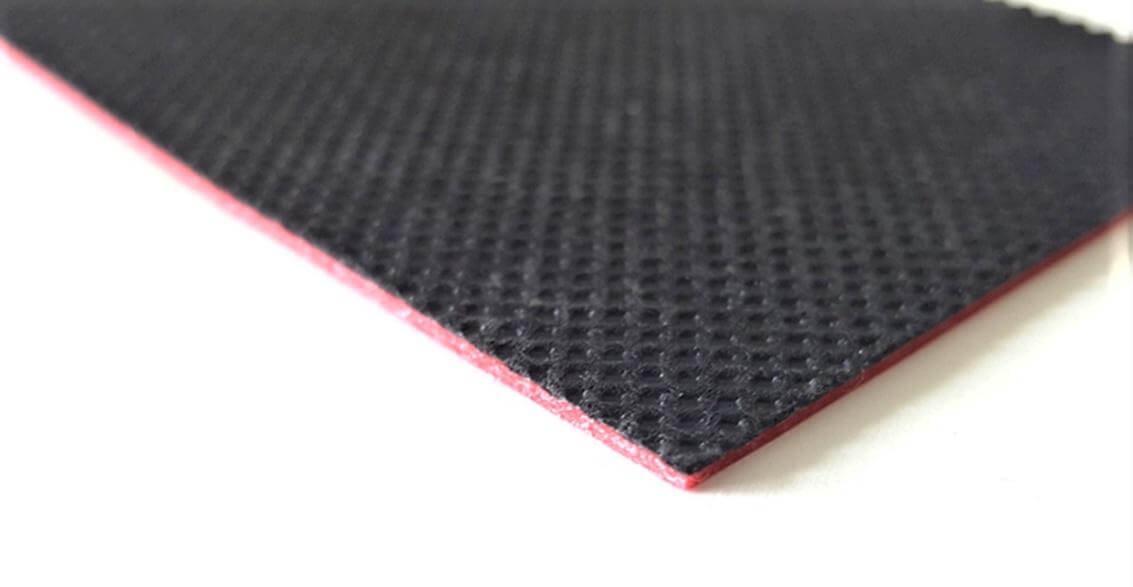

Cushion backing foam helps in better handling of the flexo printing plate in corrugated board printing.

Ground-breaking for the still young company IMC Materials was the customer’s request to further improve a proven product in corrugated post-printing. Based on many years of expertise and a brilliant idea, the development of a substructure with simple positioning behaviour on the printing cylinder succeeded.

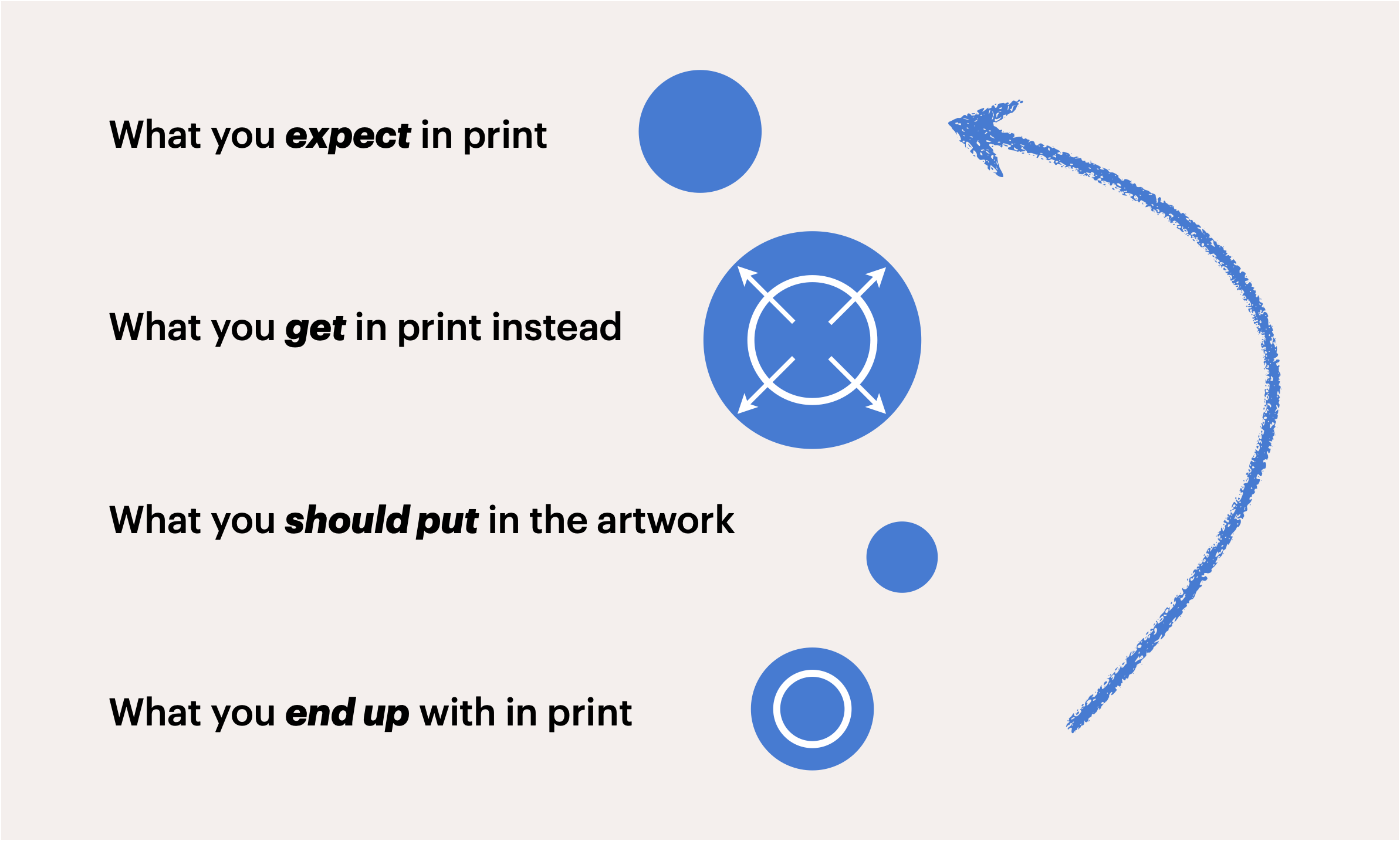

Pressure-absorbing flexo cushion backing foams have long proven themselves in direct printing on corrugated board. As a compressible base, they allow the use of thinner, harder photopolymer plates. In the printing press, they reduce the contact pressure on the printing plate in the printing nip and thus enable a lower dot gain, finer screen images and higher print quality. At the same time, they reduce the washboard effect in direct corrugated post-printing. For users, it is not only the pressure properties of the foam material that are important, but also good assembly or mounting properties.

PE foam substructure

In the European market, there are mainly flexo cushion backing foams made from closed-cell polyethylene foam, or more precisely from HDPE, a high-density polyethylene. These are characterised by good printing durability, high resilience after leaving the printing gap and controlled thickness tolerance in production. They are resistant to printing inks as well as solvents such as isopropanol, ethyl acetate and other chemicals. Compared to foams made of polyurethane, they have a lower weight and are therefore easier to handle.

Cooperation between users and manufacturers

D. & W. Flexo-Manufaktur GmbH & Co. KG as a prepress service provider used a product with an embossed surface structure that it obtained from England. However, delivery stability in lights of the upcoming Brexit and the uncertain situation of a regulated exit from the EU became more critical. Good reasons for Heiko Döring, managing director of the repro house, to look for an alternative. He found the willingness to work together with Florian von Heesen from IMC Materials, with whom they started a development project.

Non-woven material as a solution

Several approaches that were developed at IMC Materials in the course of the project were tested by D. & W. Flexo Manufaktur directly with customers in the market. From those customers everyone quickly got a concrete picture how well the new product performed.

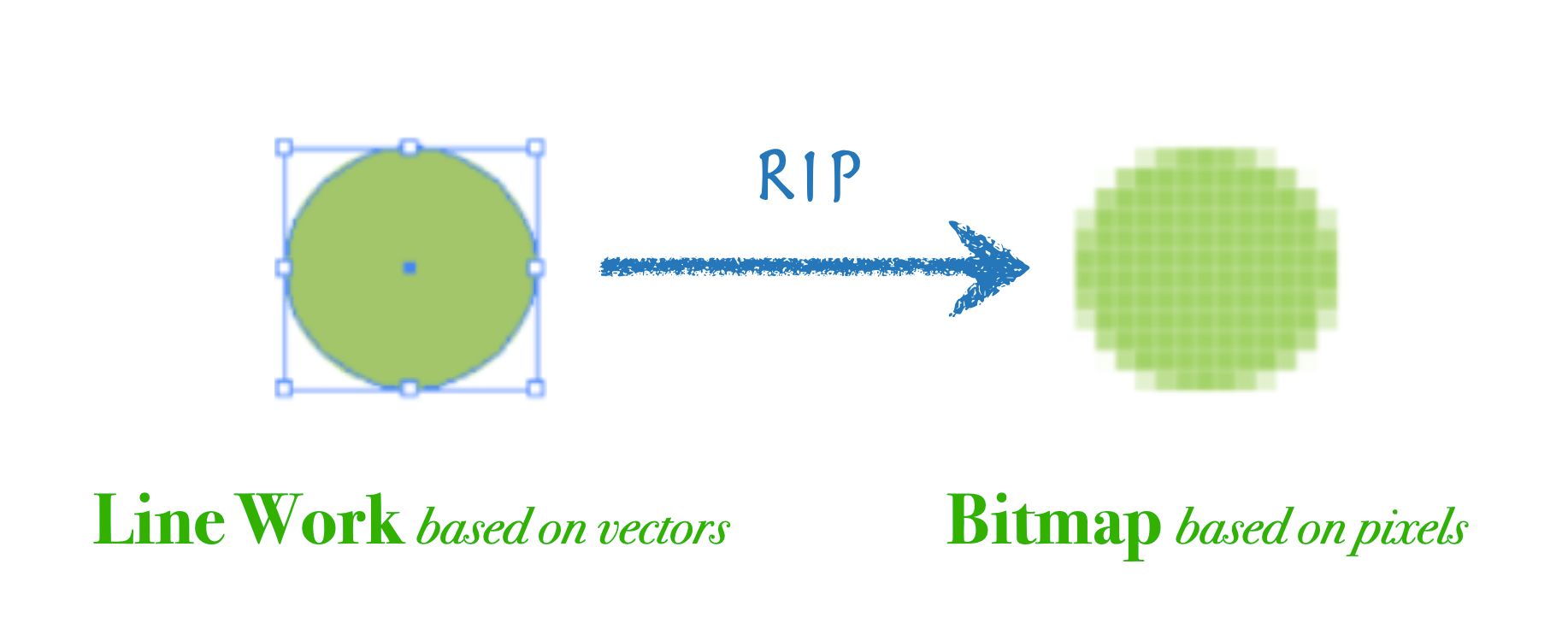

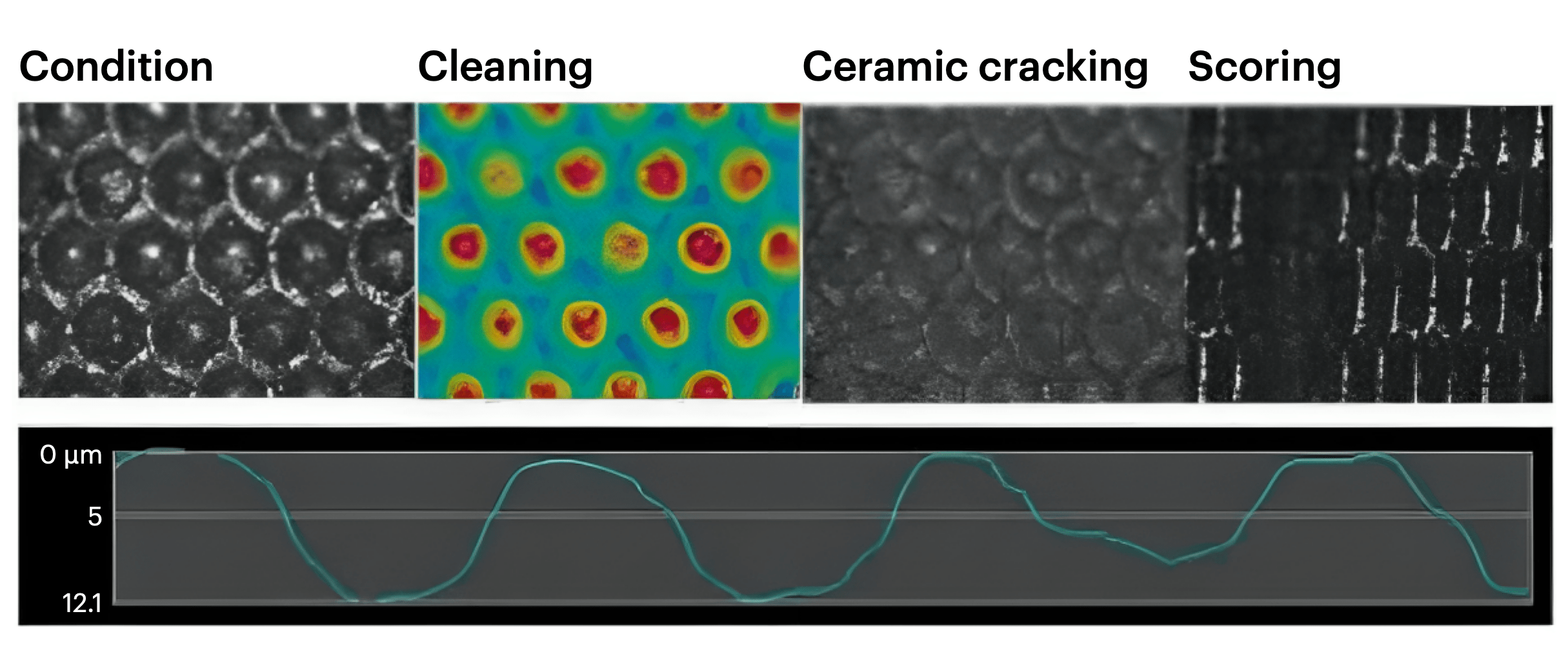

In the case of embossed flexo cushion backing foams, which IMC focused on in the first development phase, it turned out that the embossing process results in a deformed cell structure of the HDPE foam, which affects the material properties when printed. As a result, the embossed structure can become visible in the case of demanding printing images and the longevity of the product also decreases. Despite gradual improvements with embossed structures, the solution was a completely new approach, detached from the previous production method.

With the inspiration of the idea that a suitable surface structure can best take shape from a fabric-like material, IMC began looking for an appropriate fabric material and its suitable processing parameters. Materials made of fabrics are particularly adequate because they have a relatively smooth surface, are elastic and can withstand the various stresses on the flexible substructures. In addition, fabrics are available in different widths, thicknesses and colours and also match the task in terms of the cost structure. Florian von Heesen found what he was looking for in experiments with a non-woven that was laminated onto the foam sheet. The non-woven fabric makes it a little more dimensionally stable and can easily be positioned on the printing cylinder.

Production and assembly in Siegburg, Germany

“In the meantime, all of our customers have switched to this substructure,” says Heiko Döring, commenting on the successful market launch. By now, the product, whose manufacturing is under the name InnovaLux in Siegburg, has become a main product for IMC Materials.

“It was a stroke of luck for us, together with D. & W. to develop this product ”, Florian von Heesen describes the situation today. “We got direct feedback and were able to gradually improve the prototype. At the time, however, we had not yet suspected that the product would be popular with so many customers.” InnovaLux is available in standard thicknesses of 1.25 mm to 2.0 mm and in widths of up to 1,380 mm. The product has a unique selling point on the market thanks to its unique surface.

Experts for cushion backing foam for corrugated flexo printing

IMC Materials

IMC Materials is a young company starting in 2020, whose founders Florian von Heesen and Mario Busshoff have been active in flexographic printing for many years. Both owners bring decades of experience with adhesive tapes, substructures and sleeves to the new company. The company’s aim is to offer consumer products in flexographic printing with improved product properties at competitive prices.

D. & W. Flexo-Manufaktur

D. & W. Flexo-Manufaktur was founded in 2006 by Heiko Döring and Thomas Wambach in Osterwieck (Harz). The provider of prepress and creative services for packaging printing has grown dynamically since then and now has 50 employees. Corrugated cardboard post-print and flexible packaging each make up around 40% of the production of flexographic printing plates. The company relies on the very latest technologies on the market for both printing plates and consumables and supplies well-known packaging groups.

All European customers can directly place an order for InnovaLux cushion backing foam at Anyflexo Marketplace.