Maintaining your flexo equipment through regular cleaning with proper cleaning products is essential for the longevity and efficiency of your printing operation. Keeping your equipment in pristine condition will save you time and money, prevent costly downtime and ensure consistent print quality. Let’s explore the basic types of cleaning products that are key to flexo maintenance and their role in keeping your equipment in tip-top shape.

Types of Cleaning Products

Anilox Roller Cleaners

Anilox rollers are critical to the flexo printing process as they transfer ink to the printing plate. To prevent the ink from drying and building up in the cells, it’s important to clean the rolls daily. After each use, the roll should be wiped down with a clean, lint-free cloth and a suitable liquid cleaning agent. This routine should be carried out immediately after the roll is removed from the press to avoid stubborn ink residues. Depending on the type of ink you use – whether water-based, UV or solvent-based – cleaners of specific formulations effectively combat the different ink chemistries.

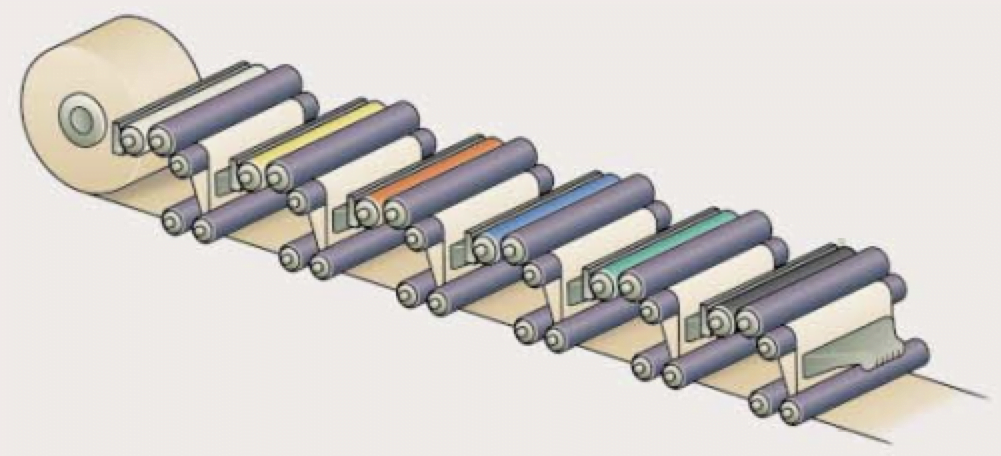

Press Cleaners

Cleaning the various components of a flexo press is essential to maintain efficiency. Ink trays, anilox rollers, ink pumps and other flexo press parts accumulate ink and other residues. A flexo press wash solution aims at thoroughly cleaning these elements and ensure that they remain free of contaminants. Regular use of such solutions will ensure the smooth operation of press components and reduce the risk of unexpected breakdowns.

Solvent Substitutes

The printing industry uses a variety of solvent substitutes, many of which are organic in nature, for cleaning purposes. These solvents include petroleum distillates such as white spirit and chemicals such as toluene, methyl ethyl ketone, cyclohexanone and chlorinated hydrocarbons. These substitutes are essential for dissolving and removing ink residues from various printing components to keep equipment clean and operational.

Adhesive Removers

Adhesives used in the printing process can leave troublesome residues. Adhesive removers are formulated to tackle these residues and ensure that surfaces remain clean and ready for use. These types of cleaners are essential for maintaining the adhesion quality of print materials and preventing contamination of subsequent print jobs.

Plate Cleaners

Flexo plates require delicate handling and cleaning to ensure their longevity and performance. Plate cleaners are specifically designed to clean these plates without damaging them, thereby improving their durability and print quality. Regular cleaning of flexo plates minimises wear and tear, resulting in consistent, high quality prints.

Degreasers

Degreasers play a vital role in removing dirt and grease from flexo parts. These products often contain high pH corrosive ingredients that break down and dissolve stubborn contaminants. The use of degreasers ensures that components are clean and free from substances that could affect their function or print quality.

Hand Cleaners

Working with flexo presses means that operators’ hands are often exposed to ink and other chemical residues. Effective hand cleaners designed specifically for the printing industry are essential. These products help to quickly remove stubborn ink stains from the skin, allowing operators to maintain hygiene and comfort throughout their shifts.

Benefits of Regular Cleaning

There are many benefits to regular cleaning and maintenance of flexo equipment. Firstly, it prevents mechanical breakdowns that can stop production and cause significant delays. Secondly, it extends the life of the equipment, making it a cost-effective practice by reducing the frequency of replacement. Thirdly, regular maintenance helps to maintain consistent print quality, which is critical to meeting customer standards and achieving optimal results.

In Conclusion

Using the right cleaning products and establishing a regular cleaning schedule are fundamental and essential to the efficient operation of flexo printing equipment. These practices not only ensure the longevity and reliability of the equipment, but also contribute to consistent and high quality print output. By investing time in proper maintenance, you can protect your business from potential downtime and improve overall productivity.