This blog was written and submitted to us by Torben Wendland

In flexo platemaking, Photopolymer printing forms (different from direct engraved printing forms) are generated through UV light exposure. The UV light is starting a chemical reaction which leads to cross-linking of plate components. The polymerisation process is only happening in areas which were exposed to UV light. This way, a latent image is created which is transformed into a relief during the washout step. Depending on the washout technology, a drying step is required, before plate finishing finalises the platemaking. The whole process can be separated into following parts:

Back Exposure (also Pre-Exposure)

A full area UV-A exposure through the transparent PET carrier film is creating the plate floor. The floor thickness is determining the final relief depth. Usually, the back exposure represents the first step in platemaking, but depending on the equipment in use, it can also be done after Laser Imaging.

© Torben Wendland

© Torben WendlandLaser Imaging

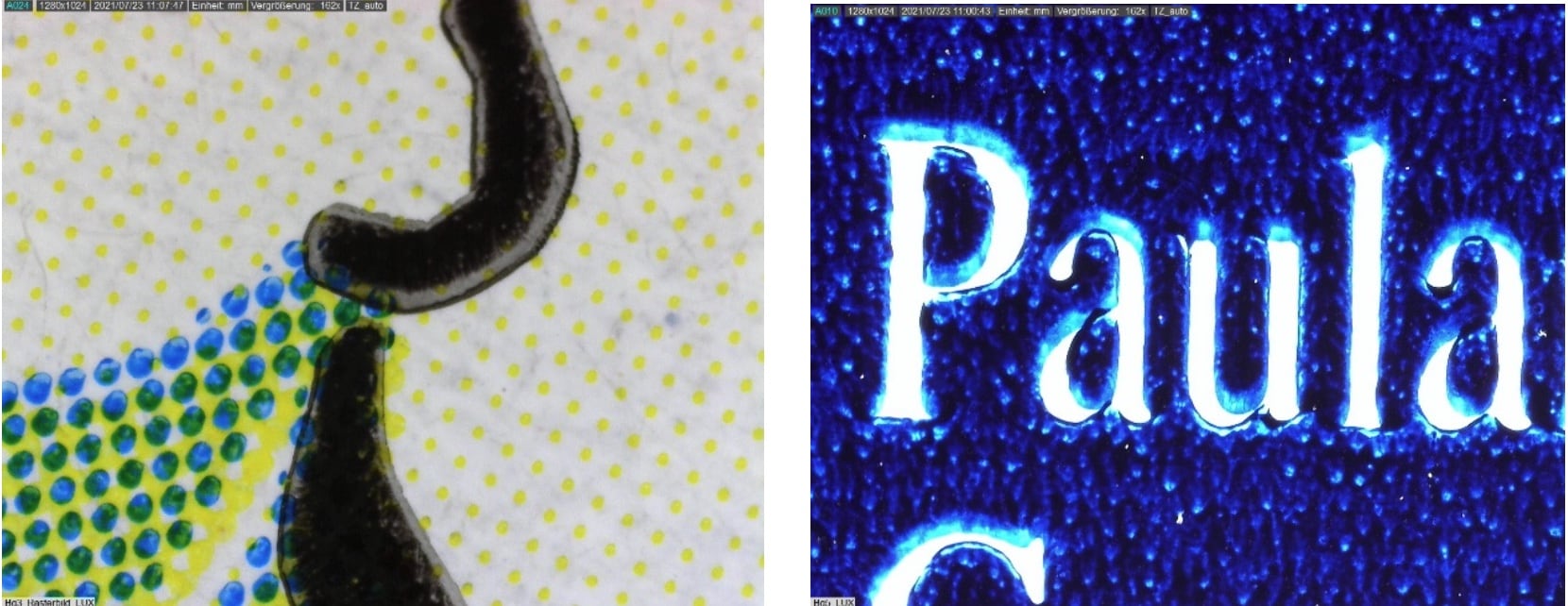

While in the past, a film was used to transfer the image onto the plate, nowadays typically a laser imager is used. For laser imaging, a certain type of plate, often referred to as “digital” plate is required (as opposed to “conventional” plates for the film process).

The laser is partly removing the black layer which is present on top of the digital plate. This layer serves as a mask in the following platemaking step. After plate imaging, an inverted image is visible on the plate.

© Torben Wendland

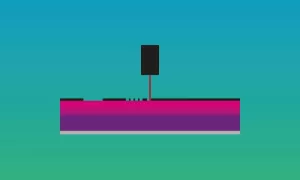

© Torben WendlandMain Exposure

The plate is then completely exposed to UV-A light from the top. This UV-A exposure, typically taking 5-15 minutes, is starting the polymerisation process in the plate and creates the latent image between polymerised and unpolymerised areas.

Washout

Depending on the plate technology, washout is done with solvent or heat. In thermal washout, the unpolymerised material is liquified by heat and removed with a developer material. In the solvent washout, the material is dissolved and removed with mechanical help. The remaining polymerised areas are forming the plate relief.

Drying

In case of solvent washout, plate drying is required until the solvent is fully evaporated from the plate. For thermal washout this step is not needed.

Plate Finishing (UV-A Post-Exposure & UV-C Detacking)

In the last step, the plate is once again exposed to UV-A light, to fully cross-link the whole plate and achieve the final plate hardness. UV-C light is used to remove the surface tackiness of the plate.