Achieving high-quality prints in flexo printing relies heavily on the quality of the flexo plates used. Technicians must possess a thorough understanding of the common technical issues that can arise with flexo printing plates and the appropriate solutions. This article is part 3 of flexo plate troubleshooting series that explores some of the most frequently encountered problems, their causes, and the technical solutions to overcome them.

Blocking

- Problem: Ink transfer from one print to the next.

- Causes: Ink drying problems, web tension issues, or substrate humidity problems.

- Solutions: Optimise ink, substrate, and dryer parameters.

© Mary Anne Enriquez

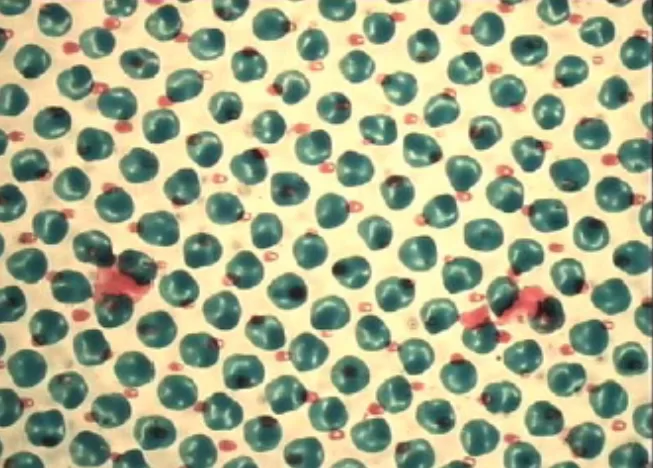

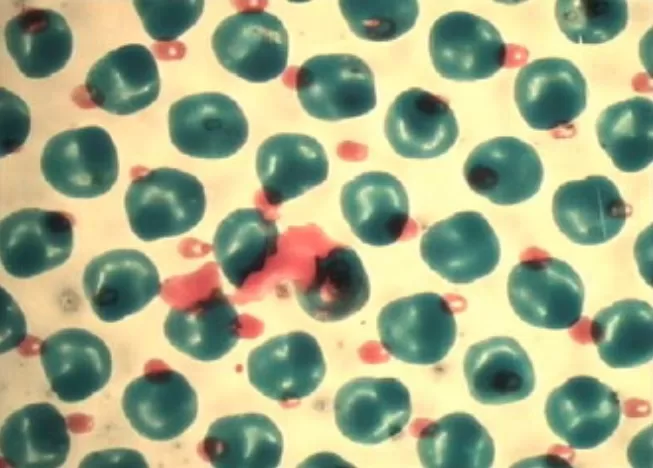

© Mary Anne EnriquezInk Splashing

- Problem: Ink splashing.

- Causes: Low ink viscosity or incorrect anilox specification (high volume or low line count).

- Solutions: Adjust ink viscosity; optimise anilox specification.

© Anyflexo

© Anyflexo © Anyflexo

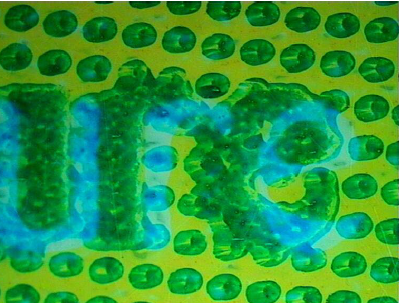

© AnyflexoMisregistration

- Problem: Misalignment in print registration.

- Causes: Plate mounting issues, equipment problems during plate making, plate orientation on imaging system, or separations from different raw material batches.

- Solutions: Ensure plate making equipment functions correctly; image separations consistently; use plates from the same batch.

© Anyflexo

© AnyflexoElement Edges Start to Print Early

- Problem: Element edges print prematurely.

- Causes: Cupping issue or high impressions between anilox and plate or plate and substrate.

- Solutions: Optimise plate making parameters (e.g., dry times); adjust impression settings on press.

© Anyflexo

© AnyflexoUnsharp Printing

- Problem: Blurred printing with high dot gain.

- Causes: Plate swelling from unsuitable solvents/cleaners causing softening during printing, high impression settings, cupping issue, or ink issues.

- Solutions: Use appropriate solvents; reduce impression settings if necessary.

© Anyflexo

© AnyflexoInk Transfer Issues

- Problem: Poor ink transfer.

- Causes: General ink issues, ink drying on anilox roller, or plate surface contamination.

- Solutions: Check ink condition; clean plate surface and anilox roller.

© Anyflexo

© Anyflexo © Anyflexo

© AnyflexoFilling-In of Fine Elements

- Problem: Fine elements filled with ink.

- Causes: High anilox to plate impression or incorrect ink viscosity.

- Solutions: Confirm anilox settings; adjust ink viscosity as needed.

© Anyflexo

© AnyflexoInk Bleeding

- Problem: Ink bleeds, obscuring screen structures.

- Causes: Improper pigments in ink or pH imbalance in water-based ink.

- Solutions: Consult with your ink manufacturer.

© Anyflexo

© AnyflexoDirty Print in Transitions of Flexo Plates

- Problem: Dirty printing in screen transitions.

- Causes: High anilox to plate impression, low ink viscosity, high anilox volume, or shallow intermediate depths or plate relief.

- Solutions: Optimise press and ink parameters; correct plate making issues.

© Anyflexo

© AnyflexoBy familiarising themselves with these common issues and their respective solutions from part 3 of flexo plate troubleshooting series, technicians can effectively fix flexo printing plate and maintain high-quality print results. Stay tuned for Parts 1 and 2 of this series, which will delve into additional problems and their remedies.

![[Flexo Flaw Fixing] Feathering](https://flexopedia.net/wp-content/uploads/2022/07/069_Feathering-jpg.webp)

![[Flexo Flaw Fixing] Low Ink Adhesion](https://flexopedia.net/wp-content/uploads/2022/07/Adhesion_Tape_Test.png)

![[Flexo Flaw Fixing] Dirty Print](https://flexopedia.net/wp-content/uploads/2022/08/dirty_print.jpeg)

![[Flexo Flaw Fixing] Ink Spitting](https://flexopedia.net/wp-content/uploads/2022/11/068_Dirty_Print-jpeg.webp)