Over the past two decades, flexographic printing has skyrocketed in popularity and now accounts for approximately 60% of the total packaging industry. Flexography has come a long way since its invention some 130 years ago. This two-part series explores the origins of flexography and its rise from the invention of the first rubber-plate rotary press to the commercialisation of UV pigments in the 1990s.

In this first instalment, we’ll journey through the early days of flexo printing, from its inception through the 1950s, the stage of its early developments. We’ll cover the major developments and challenges that shaped the industry. The second instalment will examine innovations from the 1960s to the present, highlighting the key role of the Flexographic Technical Association (FTA) in modernising the industry.

Early Developments (1853-1920s)

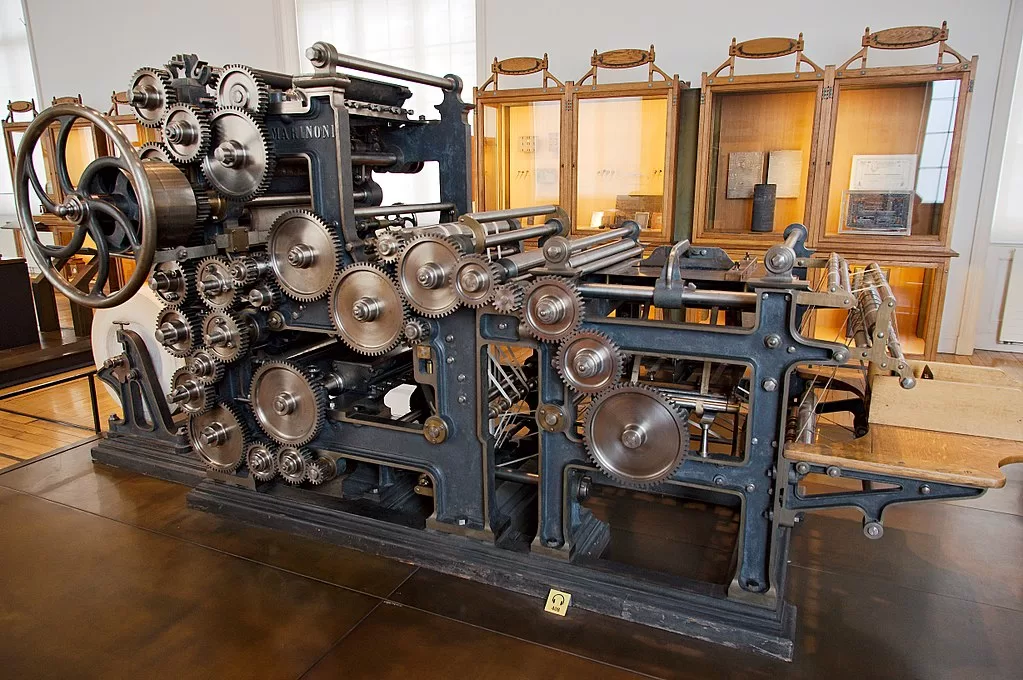

The roots of flexographic printing can date back to some 170 years ago. An English paper bag printer developed a unique rotary press in 1853. The growing demand for individually packaged products required a more efficient printing process. Enter Charles Holweg, a French businessman who, along with his brother August, founded a manufacturing company to capitalise on the booming paper bag market.

By 1903, Holweg had developed a press that used synthetic aniline dye ink, chosen for its fast-drying properties. The shift to corrugated cardboard as the official packaging material finally received the approval in 1914. The Interstate Commerce Commission’s preference for corrugated over wood was due to wartime shortages. Corrugated box manufacturers soon took the lead, building their presses, formulating inks, and developing the rubber plates essential to printing. However, these efforts often met with limited success due to improper ink formulations and primitive ink metering systems.

Ink Innovations (1920s-1930s)

The 1920s and 1930s saw considerable efforts in optimising flexographic inks. Early aniline dye inks were of poor quality, which discouraged many from using them. However, a breakthrough came in 1927 with the development of an ink that used tri-methyl methane dye dissolved in cellosolve, which was chemically fixed to prevent bleeding when wet. Soon after, companies such as National Aniline, Calco Chemical Co. and DuPont developed the first dry inks, which were eminent for their long shelf life, high melting points, solubility in alcohol, rapid solvent release, good colour properties and compatibility with aniline dyes.

In 1931, the introduction of pigmented white aniline ink containing titanium dioxide made it possible to produce opaque colours, improving the quality of flexographic printing. Despite these advances, the Great Depression stifled many potential innovations. However, synthetic rubber, introduced in 1932, provided superior resistance to harsh chemicals, improving plate durability and print quality.

Technological Advances (1940s-1950s)

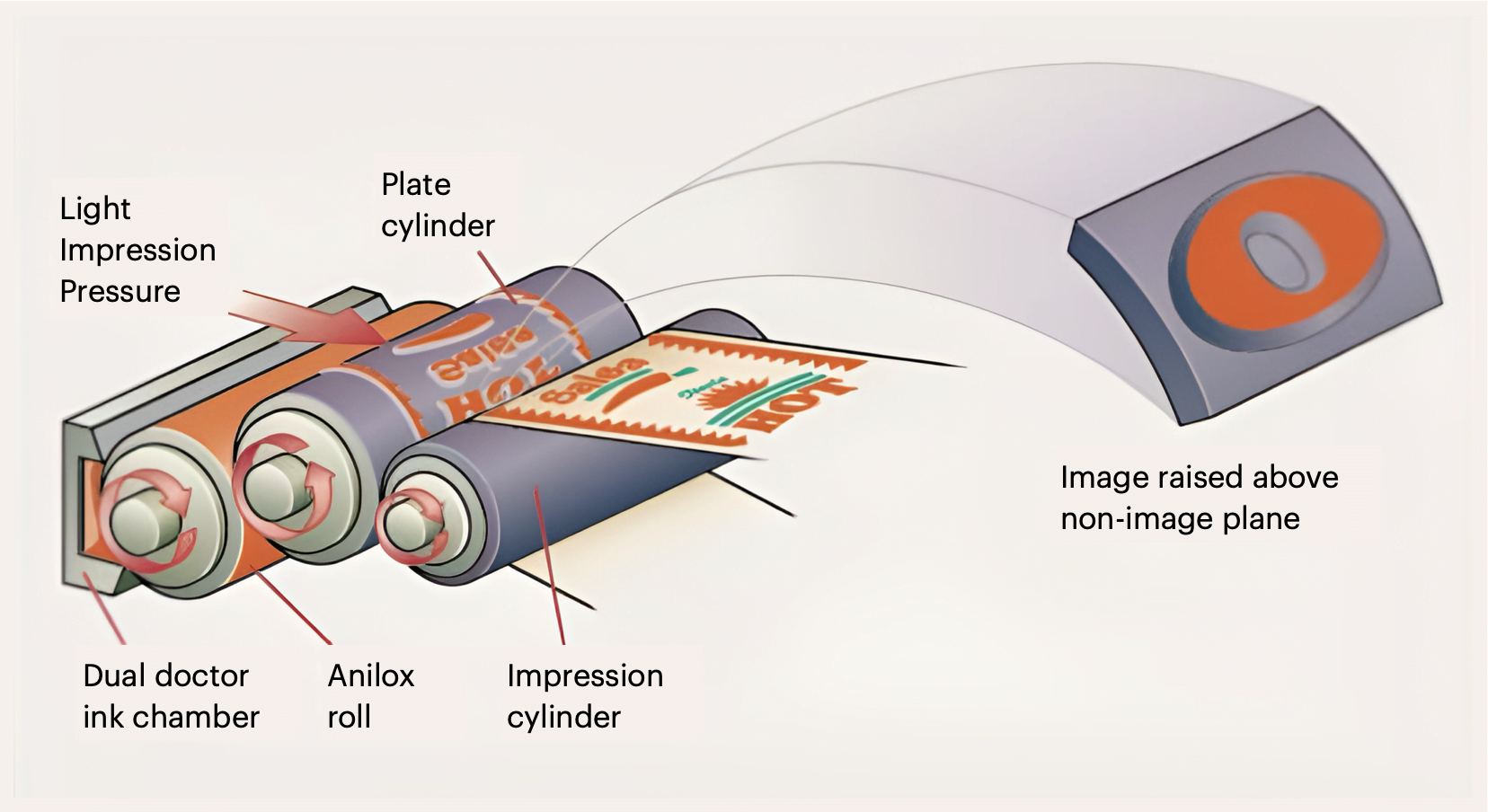

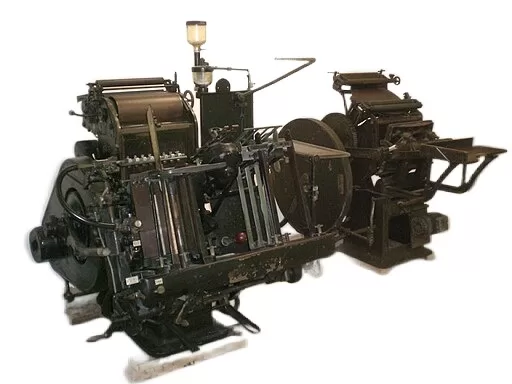

The 1940s and 1950s marked a period of significant technological advances in flexography. In 1941, Interchemical Corporation introduced the first mechanically engraved metering roll, known as the anilox roll, which revolutionised ink transfer and consistency. Despite the economic challenges of the Great Depression, innovation continued. Among these advances were the Kidder Press, designed to print on film, and the Mosstype Corporation’s “Mounter-Proofer” in the late 1940s, which addressed registration issues.

The term aniline, burdened with connotations of toxicity, was reconsidered in the early 1950s. Franklin Moss suggested renaming the process, and in October 1952, at the 14th Packaging Institute Forum in New York City, “flexography” was adopted after a ballot campaign in trade magazines.

Establishment of FTA and Modern Developments since the 1950s

By the 1950s, flexographic printing had found its niche in a wide variety of packaging, from grocery bags and counter rolls to packaging tapes and corrugated paper. The first Flexographic Forum took place in 1957, and the year after witnessed the foundation of the Flexographic Technical Association (FTA). The first Technology Forum in New York City and the publication of “Flexography Principles and Practices” in 1962 were important milestones that helped standardise and advance the industry.

Flexography has evolved from rudimentary rubber plates to sophisticated printing systems, transforming the packaging industry. While the inception and early developments of flexo printing laid the groundwork, its story is far from complete. In part two of this series, we will explore the advancements since the 1960s, including the introduction of digital technologies and environmentally friendly practices. Stay tuned to discover how modern flexography continues to evolve, driving efficiency and sustainability in packaging solutions.