In the ever-evolving landscape of the printing industry, the debate between traditional and innovative techniques remains a poignant subject for industry professionals. Two of the front-runners in this debate are flexo vs digital printing. Both methods come with their unique strengths and applications, and understanding the basic principles behind each is crucial for determining the more suitable choice for specific projects.

Comparison on How They Function: Flexo vs Digital Printing

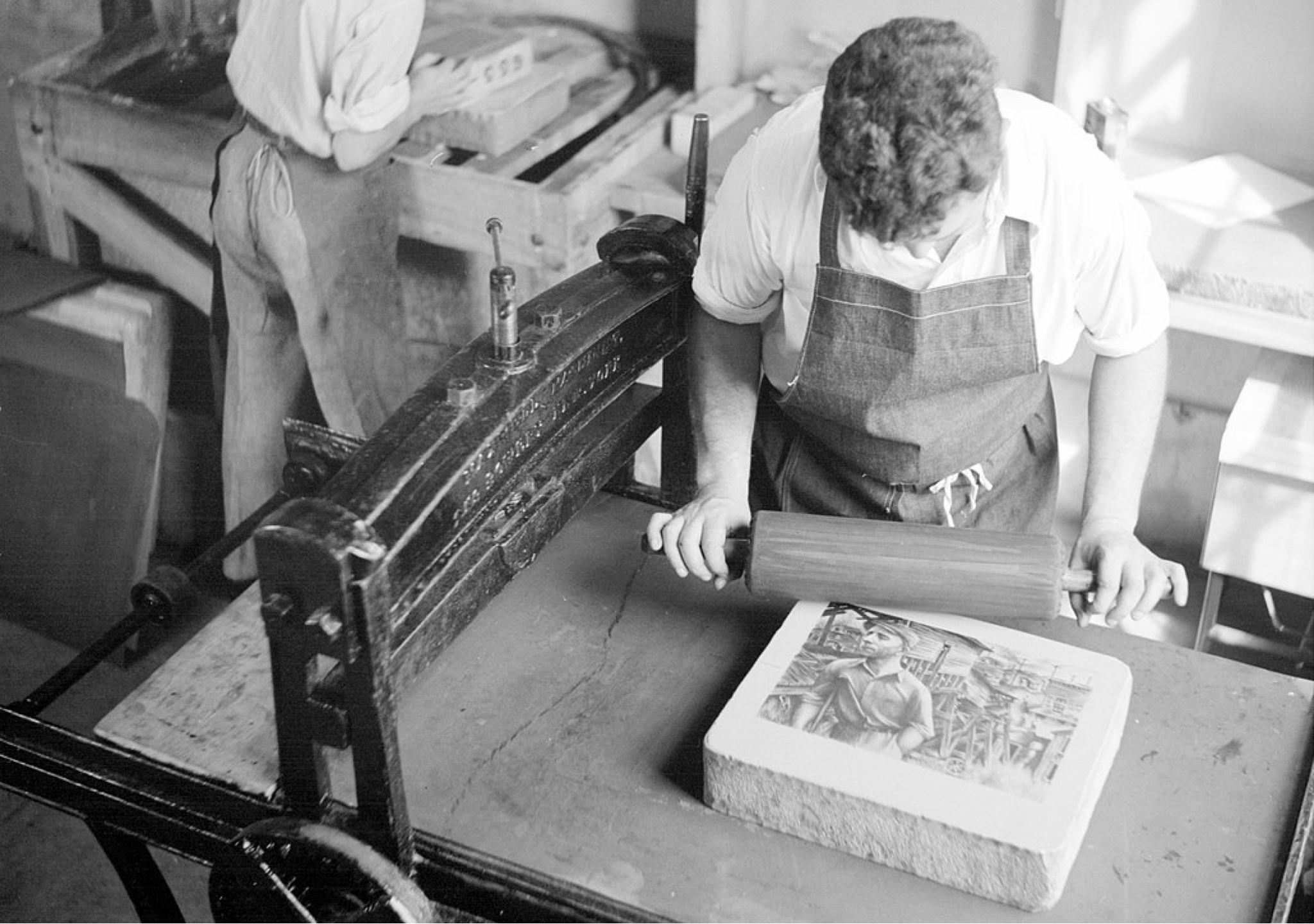

Flexo Printing – Traditional Innovator

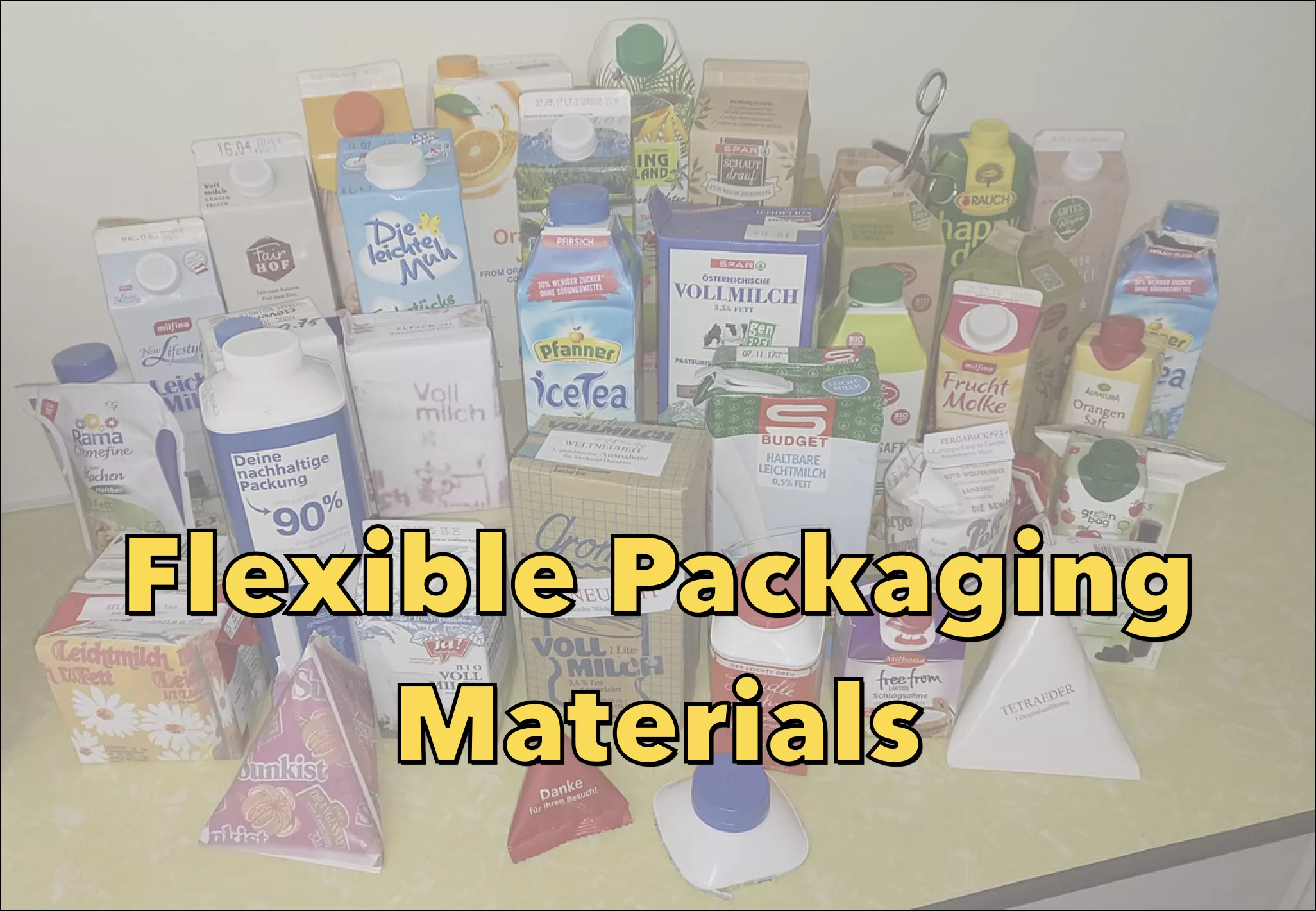

Flexo printing operates in a fashion that harks back to traditional printing techniques, utilising flexible relief plates to transfer ink onto a variety of substrates. This method involves an engraved anilox roller transferring fast-drying inks from ink fountain to the print material, making it extremely versatile for a wide range of packaging materials, including plastics, metals, paper, and cardboard. The process is known for its efficiency in high-volume runs, owing to the rapid production speeds and minimal downtime between jobs due to the fast-drying nature of the inks used.

Digital Printing – Table Turner

In contrast, digital printing eliminates the use of plates entirely and instead relies on digital files to print directly onto the substrate. This method uses electrographic, inkjet or laser printing techniques to apply ink or toner. The key advantage here is the elimination of the plate-making process, enabling much shorter turnaround times and cost-effectiveness for short to medium print runs. Digital printing shines in its ability to manage variable data printing (VDP), where each printed piece is customisable individually, such as personalised marketing materials.

The advent of digital printing has indeed turned the table in several aspects of the printing industry. Its capability for quick setup and lower costs on short runs meets the growing demand for customisation and small-volume printing. This aspect is particularly appealing in an era dominated by targeted marketing and the need for a rapid response to market trends.

Competition: Flexo vs Digital Printing

Flexo and digital printing applications overlap in packaging and label production. However, each method brings its own set of advantages that can make it more suitable depending on the project requirements. When it comes to choosing one over the other, the decision often boils down to the scope and specifics of the project.

For high-quality printing, where consistency and durability are paramount, flexo printing is typically the preferred choice, bringing lower per-unit costs at large-volume runs. Its ability to use a wide range of inks, including UV and water-based options, affords greater flexibility in the types of substrates it can print on, from delicate films to robust cardboard.

It is critical to understand that the decision-making process is inherently project-specific. Flexo printing generally involves higher initial setup costs due to the creation of custom printing plates and the setup of the printing press. However, these costs are amortised over long print runs, making the unit cost much lower in large-volume projects. The vast array of substrates and inks available for flexo printing makes it incredibly versatile, and advancements in plate and ink technology have significantly improved the quality of images in the production, rivalling that of digital printing in many cases.

Digital printing, on the other hand, offers lower initial setup costs and is cost-effective for low to medium volume runs. While it can accommodate a wide variety of substrates, the range is somewhat more limited than with flexo printing, particularly when dealing with extremely thin or thick materials. The quality of digital printing is consistently high due to the precise application of ink or toner and its ability to accurately reproduce vibrant colours and detailed images.

Final Thoughts

Both flexo and digital printing come with their unique set of strengths and applications, and the choice between them is largely dependent on the specific requirements of the print job. Flexo printing continues to be the dominant force in high-volume, industrial applications where speed, efficiency, and versatility across a range of substrates are paramount. Digital printing, with its capacity for personalisation and cost-effectiveness in small to medium runs, has undoubtedly made a significant impact on the industry, particularly for customised print projects and rapid turnaround times. While digital printing has its merits, especially in the modern context of quick changes and short runs, flexo printing maintains a competitive edge in numerous aspects, including cost efficiency at scale, substrate versatility, and improvements in print quality.

Ultimately, the choice between these two titan technologies should be guided by the specific needs of the project, with a careful consideration of the volume, substrate, and quality requirements. Nevertheless, with continuous advancements in both fields, the line between these two printing powerhouses continues to blur, marking an exciting era for the printing industry.