Flexographic printing continues to evolve as an industry, embracing innovative technologies to meet growing demands for speed, quality, and sustainability. One critical advancement in drying technology is the IR dryer. Infrared (IR) dryers provide an effective solution for drying water-based and solvent-based inks, enabling faster production speeds and enhanced print results. This guide delves into the importance of IR dryers in flexography, their operation, and their impact on modern printing processes.

What Are IR Dryers in Flexographic Printing?

IR dryers are specialized drying systems that use infrared radiation to remove moisture or solvents from printed materials. These dryers emit electromagnetic waves in the infrared spectrum, which are absorbed by the ink and substrate. The absorbed energy generates heat, evaporating water or solvents quickly and efficiently.

Designed to complement high-speed flexographic presses, IR dryers are particularly effective for drying water-based inks and coatings, making them a staple in industries focused on sustainability.

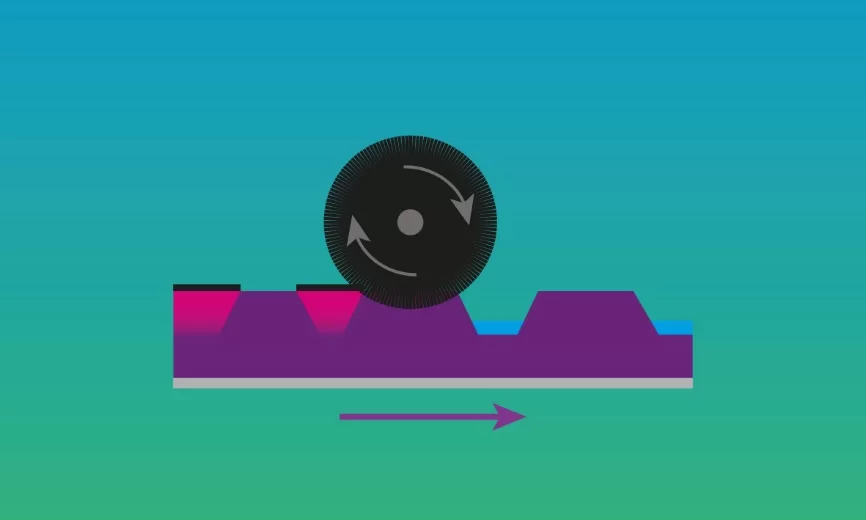

How Do IR Dryers Work?

The operation of an IR dryer can be summarized in three key steps:

- Infrared Radiation Emission: The IR dryer emits electromagnetic waves at specific wavelengths.

- Heat Absorption: The ink and substrate absorb the infrared energy, which is then converted into heat.

- Evaporation: The heat evaporates the water or solvents in the ink, leaving behind a dry, cured layer.

Unlike traditional hot air systems, which heat the surrounding air, IR dryers target the substrate directly, resulting in faster and more energy-efficient drying.

Benefits of IR Dryers in Flexographic Printing

Fast and Efficient Drying

IR dryers enable rapid evaporation of water or solvents, allowing presses to operate at higher speeds without sacrificing quality.

Energy Efficiency

By focusing energy directly on the substrate, IR dryers minimize heat loss, reducing overall energy consumption compared to conventional drying methods.

Enhanced Print Quality

Precise drying ensures that inks and coatings adhere evenly, preventing common issues like smudging, ink set-off, or uneven finishes.

Versatility Across Substrates

From paper to plastic films and cardboard, IR dryers are compatible with a wide range of materials, offering flexibility for different printing projects.

Eco-Friendly Operation

IR dryers are particularly suited for water-based inks, which produce fewer volatile organic compounds (VOCs), aligning with environmentally sustainable practices.

Applications of IR Dryers in Flexography

IR dryers are used in various flexographic printing applications, including:

- Packaging Materials: Cartons, bags, and flexible packaging.

- Labels and Tags: Self-adhesive labels, price tags, and product branding.

- Tissue and Paper Products: Napkins, paper towels, and gift wraps.

- Specialty Printing: Heat-sensitive substrates that require precise drying without excessive heat exposure.

Types of IR Dryers in Printing

Near-Infrared (NIR) Dryers

NIR dryers operate at shorter wavelengths and higher energy levels, making them suitable for rapid drying of thick ink layers or challenging substrates.

Advantages:

- Faster drying for high-density prints.

- Effective on heat-sensitive materials.

Limitations:

- May require additional cooling systems due to higher heat output.

Medium-Infrared (MIR) Dryers

MIR dryers balance energy output and heat distribution, offering a versatile option for most standard flexographic applications.

Benefits:

- Suitable for a wide range of substrates and ink types.

- Lower heat output compared to NIR, reducing the risk of substrate deformation.

Far-Infrared (FIR) Dryers

FIR dryers operate at longer wavelengths, providing gentle and even drying. They are ideal for delicate materials and applications requiring lower temperatures.

Key Features:

- Minimal risk of overheating.

- Energy-efficient for lower drying demands.

How to Choose the Right IR Dryer for Your Flexographic Press

Selecting the best IR dryer depends on several factors:

- Ink Type: Water-based inks dry efficiently with IR dryers, while solvent-based inks may require additional considerations for fume extraction.

- Substrate Properties: Heat-sensitive materials benefit from FIR or controlled MIR systems.

- Press Speed: High-speed operations require IR dryers with sufficient power and coverage.

- Drying Requirements: Assess the thickness and type of ink layer to determine the necessary drying capacity.

Maintaining Your IR Dryer for Optimal Performance

To maximize the efficiency and lifespan of your IR dryer, regular maintenance is crucial.

Tips for Maintenance

- Clean the Emitters: Dust and debris on IR emitters can block radiation and reduce efficiency.

- Inspect Reflectors: Ensure reflectors are clean and aligned to direct heat effectively.

- Monitor Heat Output: Periodically test the dryer’s temperature and adjust settings as needed.

- Check Substrate Compatibility: Verify that the IR dryer’s settings align with the substrate’s heat tolerance.

Advancements in IR Drying Technology

Smart IR Systems

Modern IR dryers are equipped with IoT-enabled sensors, allowing operators to monitor drying conditions in real-time, optimize energy usage, and perform predictive maintenance.

Variable Wavelength Emitters

Advanced IR systems can adjust wavelengths based on the ink and substrate, offering unparalleled flexibility and efficiency.

Energy Recovery Systems

Innovations in heat recovery are helping IR dryers become even more energy-efficient, reducing operational costs and environmental impact.

FAQs

What makes IR dryers different from hot air dryers?

IR dryers use electromagnetic radiation to target the substrate directly, offering faster and more energy-efficient drying compared to hot air systems that rely on heating the surrounding air.

Are IR dryers suitable for all ink types?

IR dryers are particularly effective for water-based and solvent-based inks. However, UV inks require UV curing systems instead of IR drying.

Can IR dryers handle heat-sensitive substrates?

Yes, with the right wavelength settings (e.g., FIR or controlled MIR), IR dryers can dry heat-sensitive materials without causing damage.

How do I determine the right wavelength for my application?

The choice of wavelength depends on the ink type, substrate properties, and drying speed. Near-infrared (NIR) is ideal for dense prints, while far-infrared (FIR) is better for delicate materials.

What maintenance do IR dryers require?

Regular cleaning of emitters and reflectors, monitoring heat output, and ensuring proper alignment are essential for maintaining IR dryers.

Are IR dryers energy-efficient?

Yes, IR dryers are highly energy-efficient, particularly when equipped with modern energy-saving technologies like smart controls and heat recovery systems.

Conclusion

IR dryers are an indispensable component of flexographic printing, offering rapid and efficient drying for a wide range of substrates and ink types. By harnessing infrared technology, these systems enhance production speeds, improve print quality, and support sustainable printing practices.

As advancements in IR drying continue, printers have access to increasingly flexible, energy-efficient, and intelligent systems that meet the demands of modern workflows. Whether you’re upgrading your equipment or exploring new drying solutions, investing in a reliable IR dryer will elevate your flexographic printing capabilities to new heights.