This study was conducted and the article was prepared and submitted to us by Troika Systems Ltd

A study on effects of laser cleaning (because of incorrect settings) for anilox rollers based on real observations.

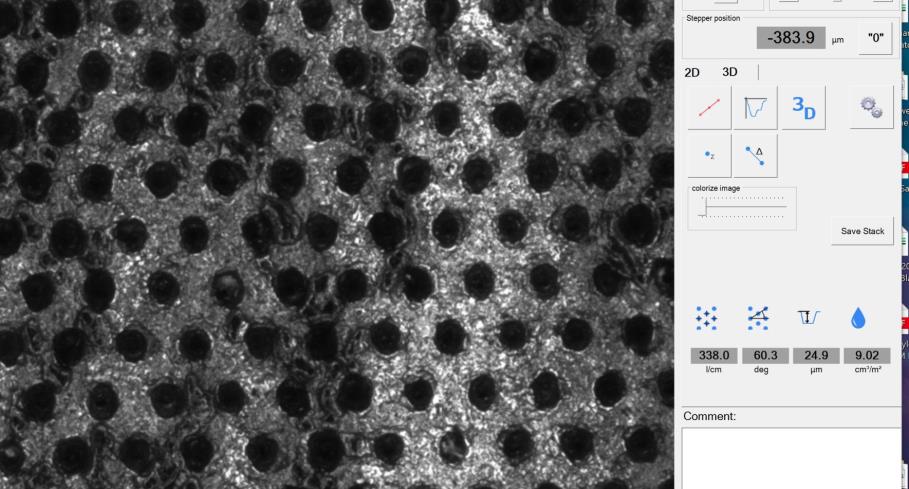

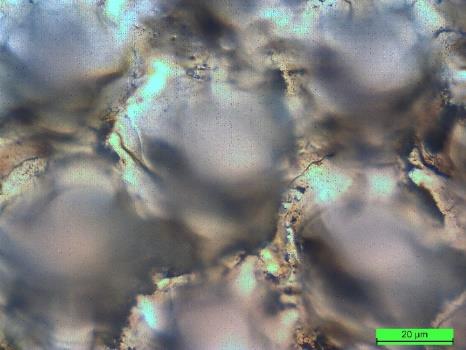

Anilox prior to laser cleaning

© Troika Systems

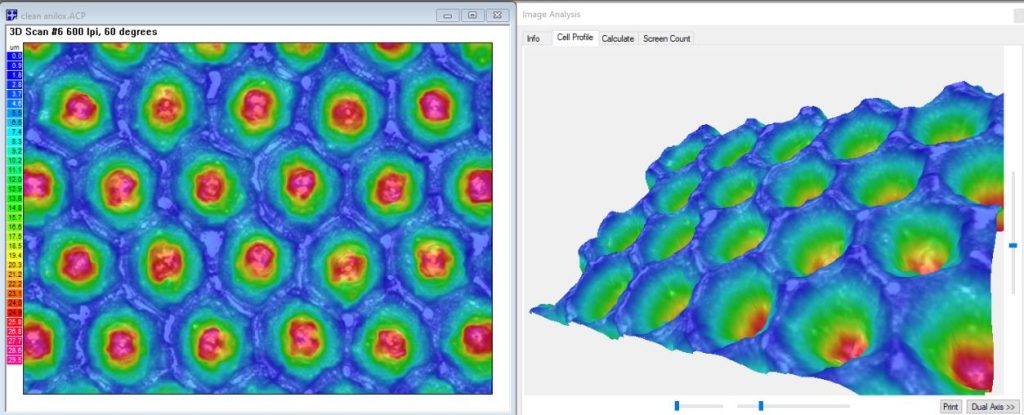

© Troika SystemsWhen laser cleaning is used to clean Anilox rollers, using the correct power and speed settings recommended by the manufacturers it was observed that a good level of cleaning, recovering the original volume (less normal wear of the ceramic) can be obtained.

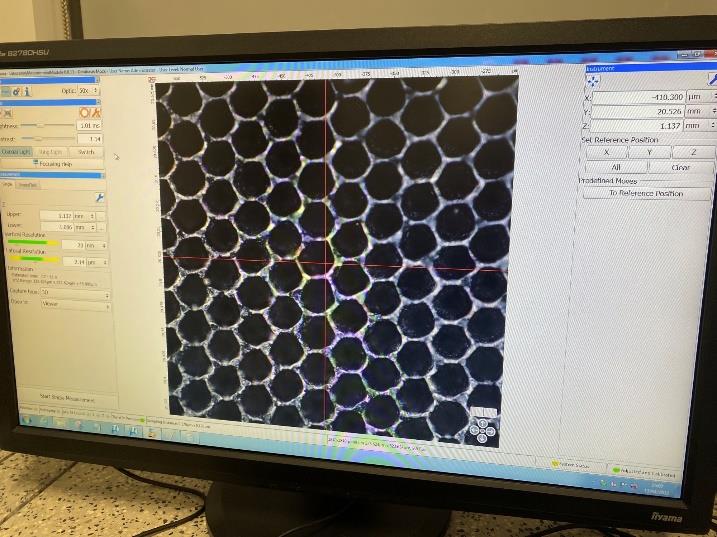

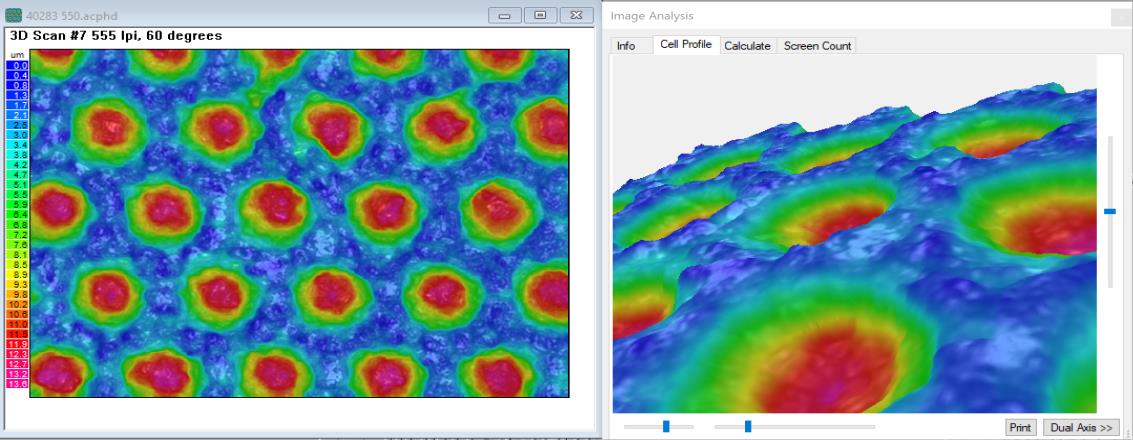

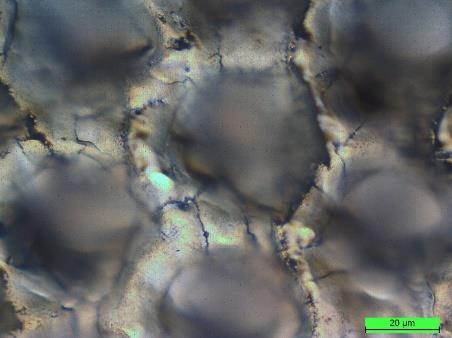

Anilox following laser cleaning

© Troika Systems

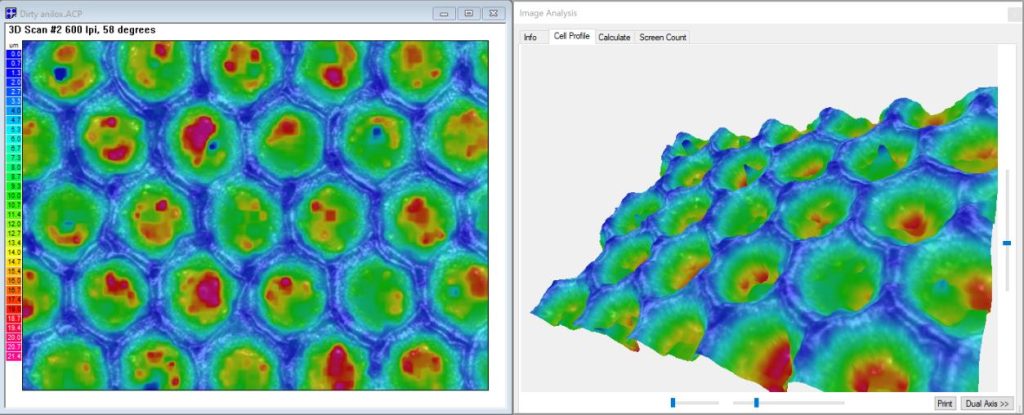

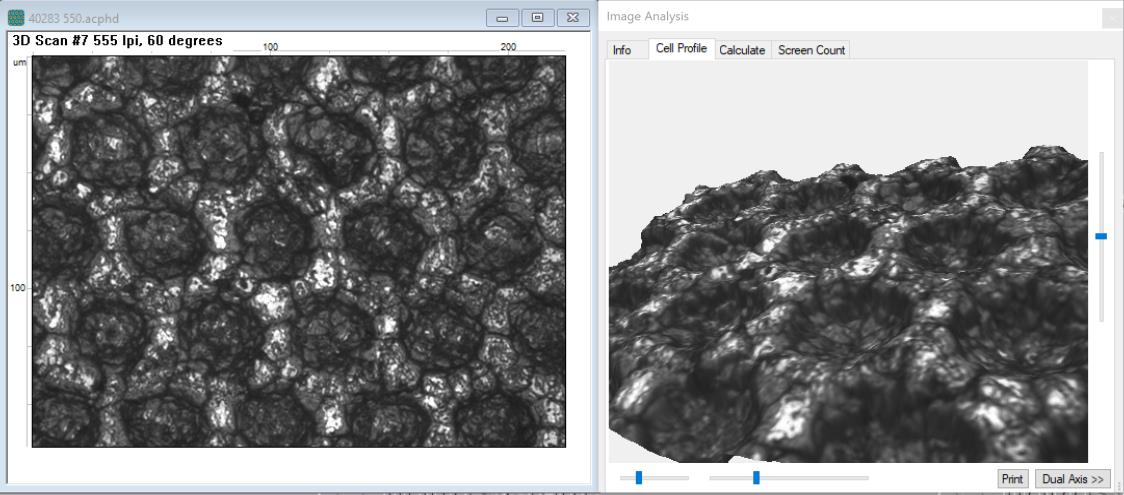

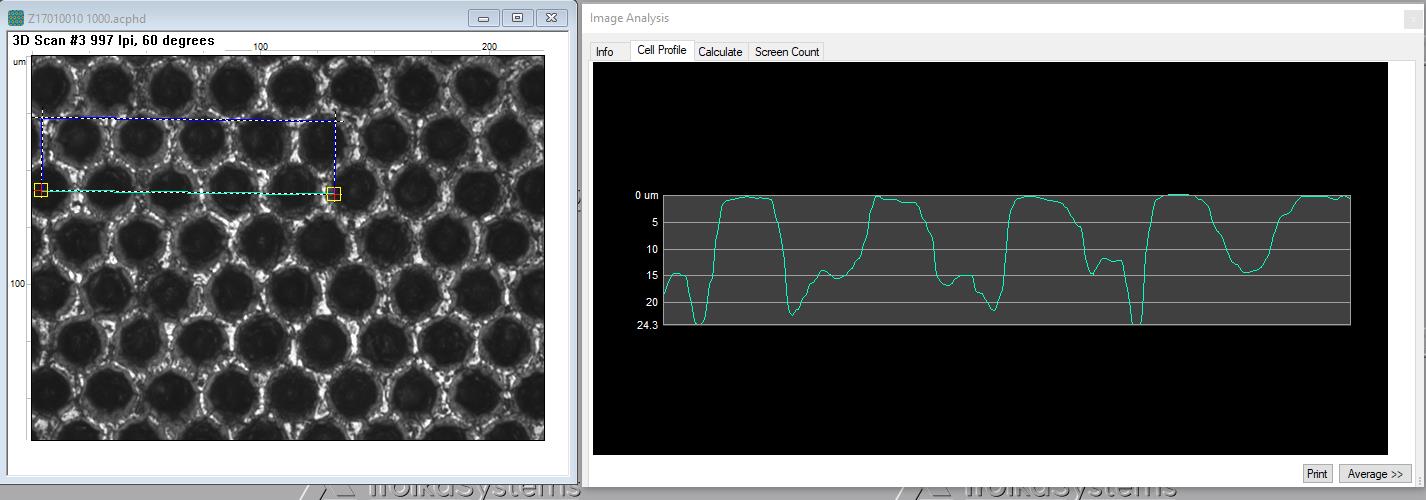

© Troika SystemsMeasurement analysis of damaged anilox

The following observations were made:

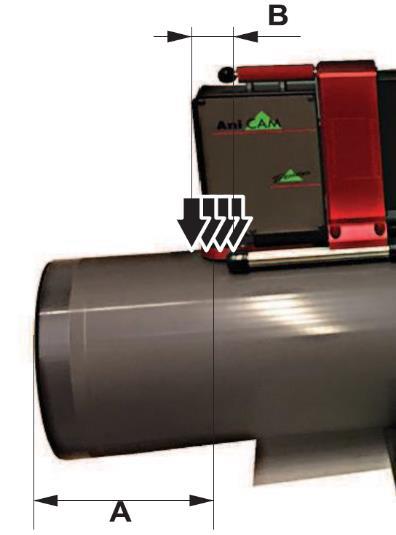

Using scanning microscopes (for this study observations AniCAM HD) that has automatic and manual settings multiple measurement points across the anilox were taken.

- Damage to cell walls

- Cracks to ceramic coating

- Cells contaminated with soot & ceramic recast

© Troika Systems

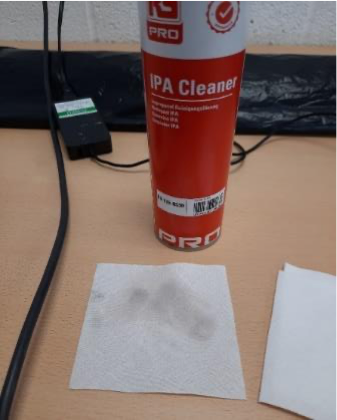

© Troika SystemsAlternate cleaning actions performed

To ensure the anilox was clean, using solvent anilox was cleaned to identify whether a buildup of soot or debris from the laser was causing the errors.

Additional cleaning methods used included, cleaning with water and mild detergent, using proprietary anilox cleaner fluid and traditional cleaning systems, these were also inconclusive in solving the issue. Although some contamination was removed from the roll, this did not impact on imagery and data capture on the damaged anilox.

Using Standard Operating Procedures, similar images and data were captured, across a range of users and compared to previous site scans.

Damage to cell walls

© Troika Systems

© Troika SystemsDamage to ceramic

© Troika Systems

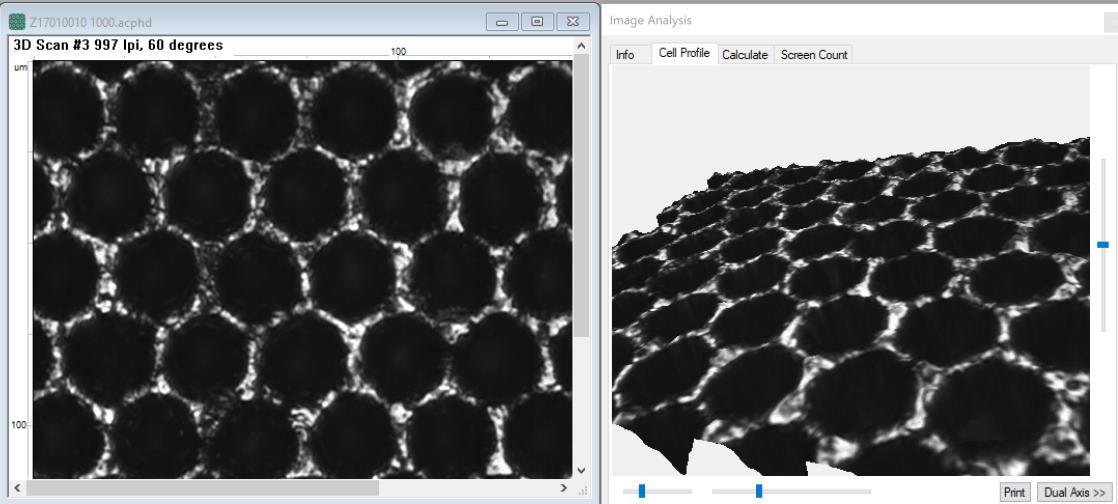

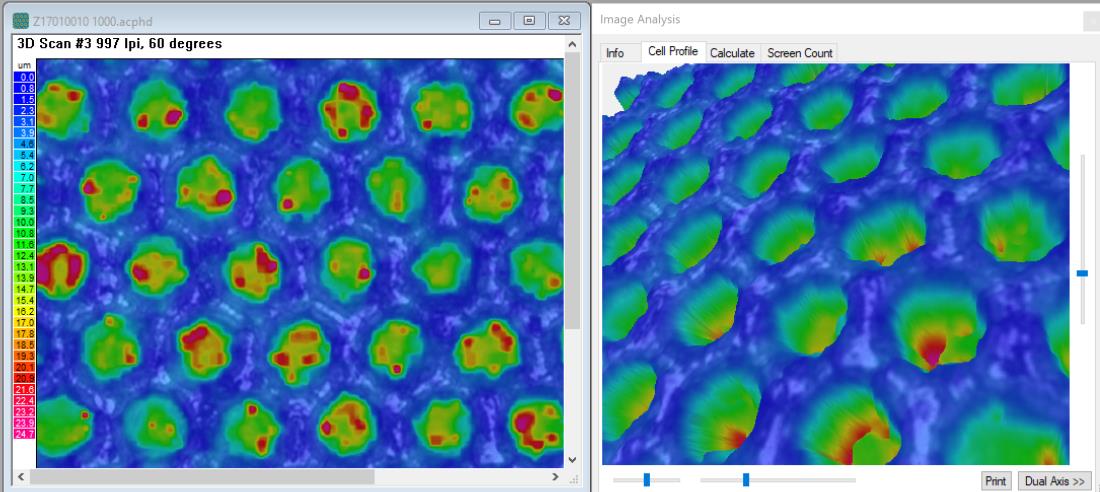

© Troika SystemsDark/Blocked cells

© Troika Systems

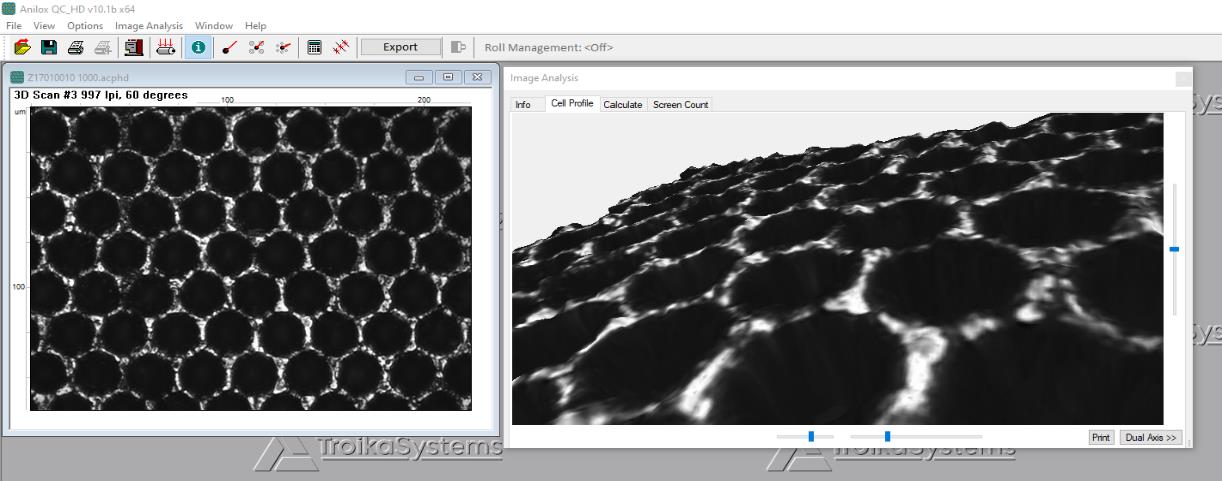

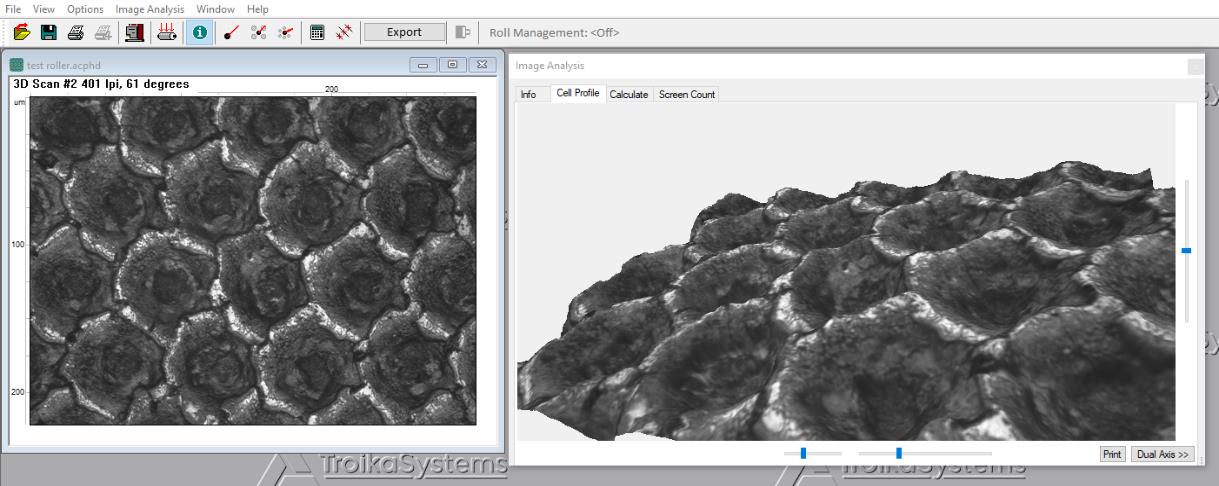

© Troika Systems3D image view

© Troika Systems

© Troika SystemsPhysical Damage

Lighting and zoom settings were also adjusted in the measurement devices to compensate for the dark cells, a combination of different exposure and lighting system (coaxial and radial) setups were performed. This provided very little difference in the data or imagery.

© Troika Systems

© Troika Systems © Troika Systems

© Troika SystemsAre we alone?

Using high-end interferometer at a scientific establishment and a range of microscope scanner (AniCAM HD in this case) device at anilox manufacturers and printers, the anilox was independently analysed.

The independent measurements show the same issue with non-reflectance from the bottom of the cells and the extended depth values, which were in line with the the microscope measurement values.

Additional analysis of other printers anilox

Extended cell depths

© Troika Systems

© Troika SystemsNon-reflectance from cell walls/bottoms

© Troika Systems

© Troika SystemsDamage to ceramic

© Troika Systems

© Troika SystemsSamples of cell damage caused by incorrect use of laser cleaning, using video microscope

© Troika Systems

© Troika Systems © Troika Systems

© Troika Systems © Troika Systems

© Troika SystemsConclusions

It was observed that the laser had caused the above damage to the anilox, from a wide range of anilox, printers and laser cleaning systems. This is not necessarily the fault of the laser cleaning system, rather that of the user attempting to provide the quickest cleaning cycle, with cleaning cycles from sub 30 minutes to 8 hours, there is a compromise between performance and risk of damage.

The user can be unaware of the consequences, correct training and considerations of use must be understood to avoid damage to their anilox.

Measurement Equipment

Using commercially available measurement equipment such as Troika AniCAM HD, covering differing technologies such as white light, interferometry and video, comparisons with high end laboratory equipment analysis the results are very similar, so it was concluded that the issue is not with the measurement devices, but the damage to the anilox.

Anilox Manufacturers

Independent anilox manufacturers have said they have found similar issues, where the power of the laser is too great, causing damage to the ceramic of the anilox, which vaporises along with the contaminant ink, the vapor then resolidifies at the cell walls and bottoms, forming a recast material that cannot reflect the light of the measurement equipment and that the cell walls and ceramic can be damaged and in some cases completely removing the ceramic layer.

Laser Cleaning manufacturers

“No singular manufacturer is at fault”

Laser cleaning for anilox rollers manufacturers are aware that cleaning with too much power or cleaning an already clean anilox can result in damage to the ceramic, this has been verified by print users who have accepted that despite the ecological benefits of laser cleaning, there needs to have been thorough tests to confirm the settings to provide a good cleaning level, without anilox damage and these programmed into the chosen cleaning system and that these settings need to be “locked in”.