Flexographic printing is renowned for its versatility and efficiency in producing high-quality prints on diverse materials. Central to its success are mounting systems, which ensure that printing plates are perfectly aligned and secured onto the press cylinders. These systems directly impact the accuracy, speed, and quality of the final print, making them indispensable tools for the modern printing industry.

This article delves into the world of mounting systems, exploring their types, functionality, and role in elevating flexographic printing to new heights.

Understanding Mounting Systems

Core Functionality of Mounting Systems

Mounting systems are designed to attach printing plates onto the press cylinder with precision and stability. By achieving accurate alignment, they ensure that the print design registers correctly on the substrate, avoiding costly errors and misprints.

Key Components of a Mounting System

- Mounting Base: Provides a stable platform for plate alignment.

- Alignment Guides: Aid in positioning the plate accurately on the cylinder.

- Pressure Rollers: Secure the plate evenly, eliminating bubbles and wrinkles.

- Camera or Optical Systems: Enhance precision by magnifying alignment marks for exact positioning.

Types of Mounting Systems

Manual Mounting Systems

These systems require operator expertise for alignment and are best suited for smaller-scale operations with fewer setup changes.

Semi-Automatic Mounting Systems

Combining manual control with automation, these systems balance affordability and efficiency, making them popular in mid-range operations.

Fully Automatic Mounting Systems

Designed for high-speed production environments, these systems use advanced technology to achieve unparalleled precision with minimal operator intervention.

Mounting Systems for Flexography

Why Precision Matters in Flexographic Printing

Flexographic printing involves transferring ink from flexible plates to a substrate. Even a slight misalignment can result in blurry prints, wasted materials, and dissatisfied clients.

How Mounting Systems Support Quality and Consistency

Mounting systems eliminate human error by using advanced features like camera-assisted alignment and automated pressure controls, ensuring every print run starts on the right note.

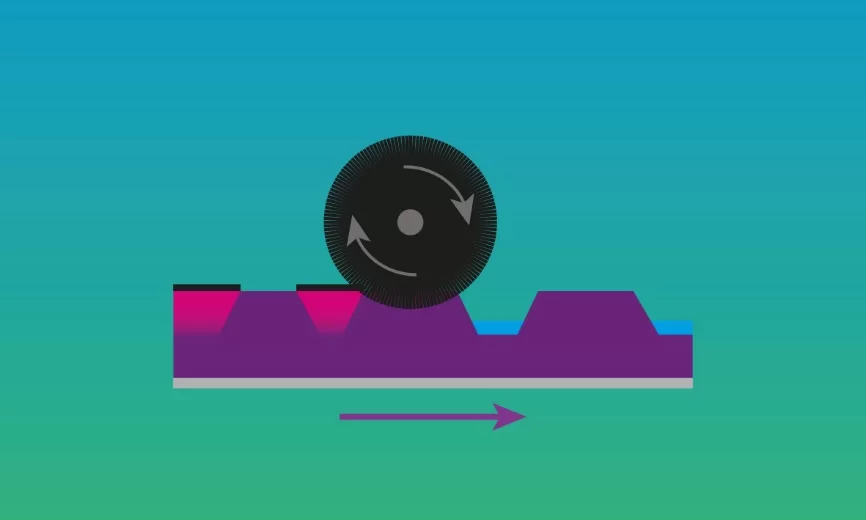

How Mounting Systems Work

Plate Preparation and Alignment

The process begins with cleaning the plate and applying adhesive mounting tape to the cylinder. Proper preparation is critical to achieving consistent results.

Steps in the Mounting Process

- Position the Plate: Using alignment guides or cameras, position the plate over the cylinder.

- Secure the Plate: Apply pressure evenly to adhere the plate without bubbles or gaps.

- Verify Alignment: Double-check marks to ensure perfect registration before starting the press.

Features of Advanced Mounting Systems

Camera-Assisted Alignment

High-resolution cameras magnify alignment marks, enabling precision down to microns.

Automated Pressure Adjustment

These systems evenly distribute pressure during mounting, preventing uneven adhesion or wrinkles.

Benefits of High-Quality Mounting Systems

Reduced Setup Times

Automation and advanced features shorten the time needed to mount plates, boosting productivity.

Enhanced Print Accuracy

Perfectly aligned plates result in crisp, vibrant prints with no registration errors.

Challenges in Plate Mounting

Common Issues in the Mounting Process

- Misalignment: Leads to blurry prints or overlapping colors.

- Bubble Formation: Creates inconsistencies in the print surface.

Solutions for Achieving Perfect Alignment

- Use high-quality mounting tapes with consistent adhesion.

- Invest in systems with optical alignment tools for added precision.

Mounting Tapes and Their Role

Importance of Choosing the Right Tape

Mounting tape acts as the intermediary between the plate and the cylinder, providing the grip and cushioning needed for consistent performance.

Tape Thickness and Adhesion Characteristics

- Thin Tapes: Ideal for high-resolution prints.

- Cushioned Tapes: Absorb vibrations, suitable for textured or uneven substrates.

Maintenance of Mounting Systems

Cleaning Guidelines

Regularly clean the mounting base, cameras, and rollers to prevent debris buildup that could affect accuracy.

Inspection and Calibration Tips

Periodic inspections of pressure rollers and alignment systems ensure consistent performance over time.

Innovations in Mounting Systems

Integration with Digital Technologies

Modern mounting systems now feature IoT connectivity, allowing for real-time monitoring and diagnostics.

Sustainable and Eco-Friendly Designs

Energy-efficient models and recyclable mounting tapes are making mounting systems more environmentally friendly.

Conclusion

Mounting systems are the foundation of successful flexographic printing, offering the precision and reliability needed to meet the demands of today’s fast-paced industry. From manual to fully automated systems, these tools are vital for achieving accurate plate alignment, reducing setup times, and delivering superior print quality.

Investing in the right mounting system is not just about enhancing productivity—it’s about ensuring consistency, minimizing waste, and positioning your business for long-term success.

FAQs

What is a mounting system in flexography?

A mounting system is used to securely attach printing plates to the press cylinder with precision for accurate printing.

What are the benefits of automated mounting systems?

They reduce setup times, enhance alignment accuracy, and minimize human error during the plate-mounting process.

How do mounting systems prevent misalignment?

Features like camera-assisted alignment and precise pressure controls ensure perfect registration of the plate.

Are manual mounting systems still relevant?

Yes, they are cost-effective for smaller operations or businesses with lower production volumes.

What role does mounting tape play in the process?

Mounting tape provides the necessary adhesion and cushioning between the plate and the cylinder, ensuring consistent performance.

Can mounting systems improve sustainability?

Yes, by reducing material waste, supporting energy-efficient operations, and incorporating eco-friendly materials.

![[Flexo Flaw Fixing] Screen Dot Inaccuracy](https://flexopedia.net/wp-content/uploads/2022/05/039_Deformed_Dots.png)