Flexo vs offset printing are two of the most prevalent techniques for jobs demanding consistent quality and long printing runs in the printing industry, each offering unique advantages depending on the specific requirements of the project at hand. While they share some similarities in their aim to efficiently produce high-quality prints, understanding their distinctions — particularly in terms of printing plates, inks, and substrates — is crucial for businesses deciding which technique best suits their needs. So, what sets flexo and offset printing apart? Let’s delve into the techniques of flexo and offset printing before exploring their discrepancies!

What is Flexography?

Flexo printing is a method that employs a flexible relief plate to print on a wide array of substrates. In the flexo printing process, images are roll-fed onto a web. Each colour is created using a photopolymer plate wrapped around a rotating cylinder. Similar to letterpress, the graphics and text for each colour are raised on the printing plate, with only the raised parts receiving ink.

The flexibility makes flexo an ideal choice for packaging materials, including plastic, metallic films, cellophane, and paper. The technique is highly favoured for its adaptability in printing on irregular surfaces and its swift production speed, particularly for large volumes, making it a go-to choice for labels, packaging, and wallpaper industries.

What is Offset Lithography?

Offset printing, on the other hand, is a technique that transfers an inked image from a plate to a rubber blanket (usually made of aluminium), then onto the printing surface. This method gains its name from the process of transferring an inked image from the plate onto the blanket.

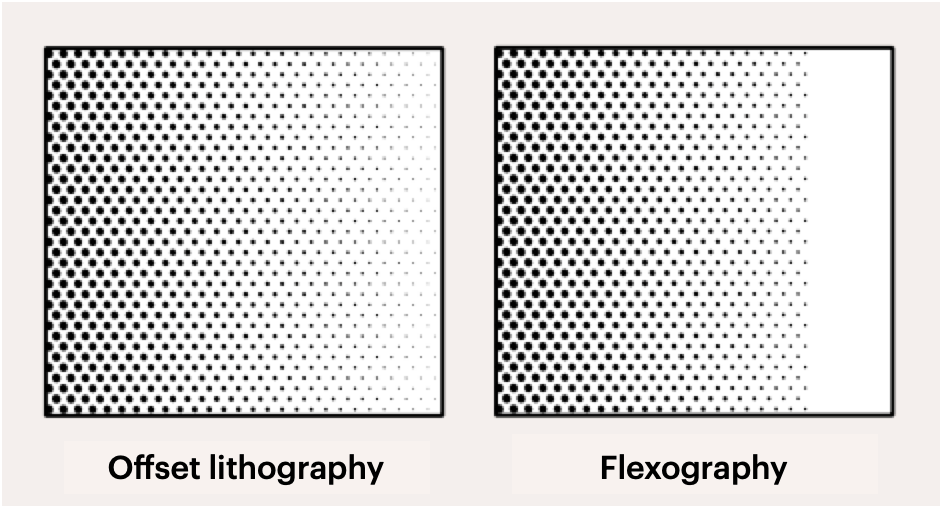

Renowned for its exceptional quality and clarity, it is particularly well-suited for detailed graphic work on paper products. Offset is the preferred method for a wide variety of printing needs ranging from newspapers, magazines, brochures, and books, to stationery and much more. The meticulous colour reproduction and high-resolution output render it an excellent choice for items where visual impact is paramount.

Flexo vs Offset Printing Techniques

Despite their differences, flexo and offset printing share some common ground. Considering these similarities between them would provide clarity on their main differences.

Common Ground

Both techniques can achieve high-quality print outputs, making them suitable for efficient high-volume runs. Furthermore, each method has been evolving with technological advancements, incorporating digital capabilities to enhance precision, speed, and eco-friendliness.

In terms of techniques, they share the similarities as follows:

- Both processes necessitate a printing plate or another image carrier.

- Wet ink is used in both methods.

- They cater to a wide array of substrates.

- Due to their setup times and the requirement for image carriers, these processes are deemed suitable for long print runs.

- Notably, flexographic printing is versatile enough to be performed on almost any flexible surface, whereas offset printing is restricted to flat surfaces.

Distinctions between Flexo vs Offset Printing

The distinctions between flexo and offset printing become apparent when examining the specifics of the following parameters.

Printing Plates

Flexo uses flexible rubber or photopolymer plates for rotary printing, allowing it to print on a multitude of substrates with various textures and chemical compositions. Laser technology is employed to imprint the relief image on the plate, which is then dissolved using a solvent or water solution in a processing unit to set it. Once printed, the image is directly applied to the substrate. Properly stored printing plates can be reused multiple times until replacement becomes necessary. This flexibility also contributes to shorter setup times, as the plates can be changed and stored with relative ease.

Offset printing, in contrast, utilises rigid aluminium plates that are more suited to smooth paper or card stock. Depending on the type of offset press, offset printing can be either a flat-bed or rotary procedure. The intricate process of plate creation and setup in offset printing typically results in longer preparation times compared to flexo.

Inks

In the realm of inks, flexo printing is known for its use of fast-drying, low-viscosity inks, enabling rapid production speeds and the ability to print on non-absorbent materials. Apart from the standard CMYK colour printing, spot colours can also be pre-mixed or mixed on-site depending on requirements. UV-cured inks permit faster press speeds and can remain on the press all day without necessitating print station cleaning. Water-based inks, however, should be cleared from presses during downtime to prevent drying on rollers and ink trays.

In offset printing, however, each of the standard CMYK colours has its own print station. Spot colours are formed through the combination of process colours. Offset printing uses oil- or water-based inks that require more drying time and are best suited for absorbent paper-based substrates. The specific nature of offset inks delivers a superior depth of colour and detail, which is crucial for high-end graphical prints.

Substrates

The choice of substrates is another area where flexo and offset printing diverge significantly.

Flexo’s versatility allows it to print on a broad spectrum of materials, from flexible packaging to corrugated cardboard, from absorbent to non-absorbent materials like foil, cellophane, fabric, metal, cardboard, or plastic. Thus, it is highly adaptable for various application, such as envelopes, retail bags, wallpapers, newspapers, labels, etc.

Offset printing excels on paper products, offering unparalleled quality and finesse on flat, smooth surfaces. Its application lies in printing on materials like metal, cardboard, vinyl, and paper. It is less adaptable to the wide range of materials that flexo can handle with ease.

Making the Right Choice for Your Business

When deciding between flexo and offset printing for your business, consider the specific requirements of your project. Flexo printing, with its broad substrate compatibility, fast-drying inks, and cost-effectiveness for high-volume orders, is particularly well-suited for packaging and labels. The technique’s adaptability and efficiency in producing large quantities make it slightly more favourable for businesses looking for flexibility and speed.

Offset printing, though, is unmatched in quality for detailed graphic work on paper materials, making it ideal for projects where visual excellence is paramount. Its suitability for high-quality brochures, magazines, and other graphic-intensive products cannot be overstated.

However, for most packaging applications and projects requiring versatility and rapid production, flexo printing emerges as the method of choice. Its ability to print on a vast array of substrates, coupled with technological advancements improving quality and efficiency, positions flexo as a highly adaptable and cost-effective solution for businesses seeking to balance quality with economic considerations.