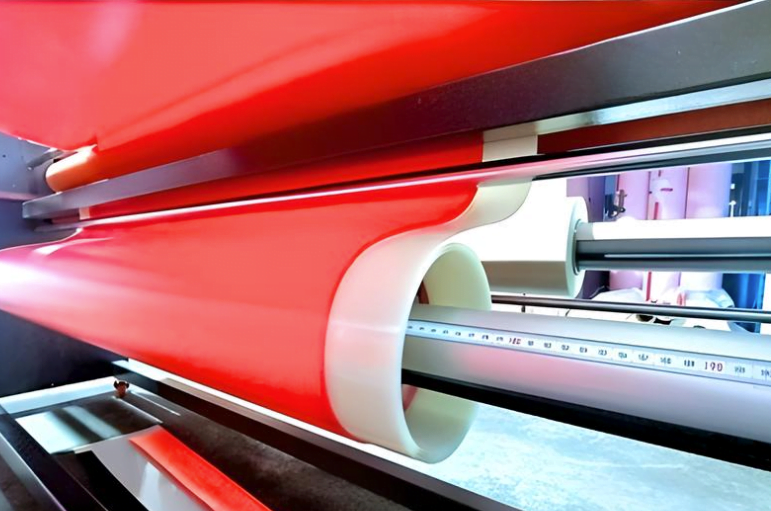

In the world of flexographic printing, the pivotal role of ink cannot be underestimated. Ink stands at the heart of the flexographic printing process, constituting a blend of resins, pigments, additives, and solvents. The selection of the right ink is a critical factor that influences various aspects such as lead time, substrate compatibility, and overall print quality. Ink Types in Flexographic Printing

Understanding the complexities of ink selection begins with acknowledging crucial considerations such as surface tension. Inks inherently migrate towards surfaces with higher dyne levels. Achieving an optimal surface tension configuration is vital to facilitate efficient ink transfer to the substrate, ensuring uniform coverage and impeccable results.

Moreover, the synergy between different flexo inks and various image carriers and substrates requires a meticulous approach. Each ink type is intricately crafted to cater to specific application needs, with factors like chemical compatibility, print speed requirements, regulatory adherence, and substrate characteristics playing significant roles in the selection process.

Unveiling the Spectrum of Flexo Inks and Their Applications

The realm of flexographic printing predominantly features four primary types of inks, categorised into two fundamental groups. Let’s embark on an in-depth exploration of each flexo ink type and their respective applications.

Volatile Inks

These compositions incorporate liquid solvents such as water or alcohol, evaporation of which leads to the imprinting of images on surfaces.

Water-Based Inks

Primarily comprising water and pigments, additives like defoamers and drying agents enhance the performance of water-based inks. Renowned for their high surface tension, these inks find prominence in the corrugated packaging domain. They are particularly recommended for elastomer plate applications due to their composition.

Solvent-Based Inks

Composed of alcohols, acetates, and pigments, solvent-based flexography inks typically exhibit lower surface tensions compared to their water-based counterparts. One usually prefer EPDM elastomers for optimal compatibility. These inks excel in printing on plastic shopping bags and industrial films.

Energy Curable Inks

Positioned as inks that dry through intermolecular bonding, securing a lasting print on the substrate.

UV-Based Inks

Featuring prepolymers, monomers, photo-initiators, and pigments, UV-based inks rely on exposure to UV light or electron beams for curing and adhesion. With higher viscosities, these inks align well with EPDM elastomers for flexographic applications, commonly found in the exterior packaging of food products.

Oil-Based Inks

Comprising hydrocarbons, pigments, and occasionally soy oil, oil-based inks integrate harsh solvents like naphtha or hexane. Nitrile elastomers are often recommended, making them ideal for the publication printing sector.

Understanding the Science Behind Flexographic Ink Selection

Embracing a scientific approach to ink selection involves delving into the nuanced relationship between surface tension, substrate compatibility, and ink performance. The confluence of these factors underscores the importance of meticulous evaluation to achieve outstanding print quality and operational efficiency.

Intricacies associated with substrate selection further underscore the need for tailored ink solutions to address unique challenges presented by materials ranging from corrugated board to films and foils. Collaborating with reputable substrate and ink suppliers offers valuable insights into optimising print outcomes to meet specific graphic, physical, and chemical specifications for a flawless end product.

The classification of flexo inks into volatile and energy curable categories illuminates the diverse mechanisms at play in ink-substrate interactions. While volatile inks rely on liquid solvents for image transfer, energy curable inks solidify through intermolecular bonding, cementing the ink on the substrate.

In Summary

The harmonious integration of ink types with compatible substrates lays the foundation for successful flexographic printing, enabling enhanced print quality and operational efficiency. Consult industry resources on sustainable printing practices to drive environmentally conscious and high-quality print outcomes, embracing a holistic approach for unparalleled results.