The printing industry features several different operational methods and types of printing presses. There are eight main types of presses in use, each with its unique use depending on the size, colour, effect, and quantity required. Choosing the best printing method is critical, and so is partnering with a reliable supplier.

5 Different Types of Printing Presses

1. Digital Printers

Digital inkjet printers can print on a wide range of materials such as paper, plastic, canvas, and even doors and floor tiles. These printers are ideal for short to medium runs because they are controlled by a computer. The quality of your prints is determined by the machine, so look for machines that can continuously feed the substrate.

2. Screen Printers

There are two types of screen printing: flat and rotary, which differ slightly in the process. In both cases, the ink can adhere to a variety of materials, including paper, textiles, ceramics, wood, and metal.

- Flat Screen Printing: The squeegee is then moved across the screen, forcing ink through the mesh and producing a print.

- Rotary Screen Printing: The ink is forced through the mesh by the squeezed-out squeegee as the mounted cylinder rotates.

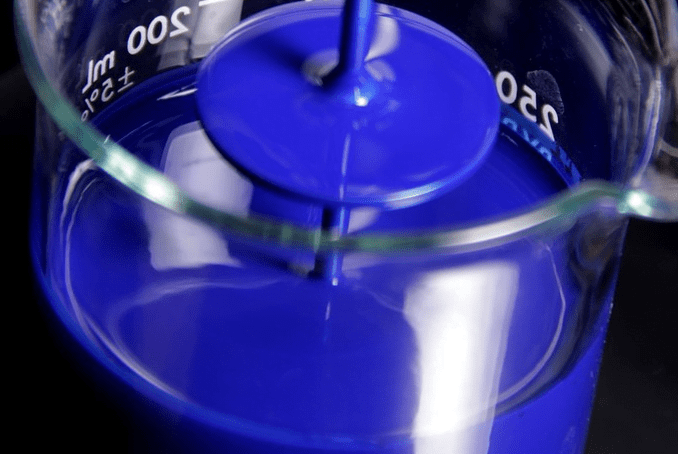

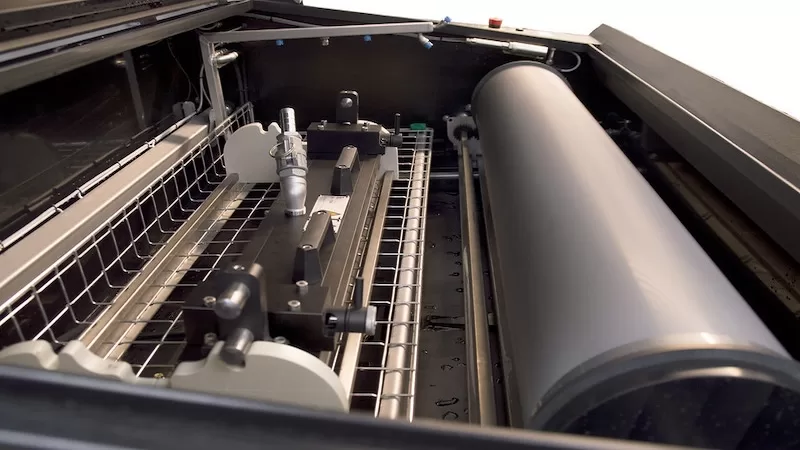

3. Flexographic Printing Machine

Flexographic printing can be done on a variety of substrates such as film, paper, foil, and non-woven. Elastomer or polymer image carriers, such as sleeves, cylinders, and plates, are commonly used in flexographic printing. Ink is transferred from the ink pan to the image carrier via an anilox roll before being printed onto the substrate.

4. Offset Printers

Offset lithography, a type of printing method, necessitates the use of a printing plate, which is typically made of aluminum and contains an image of the material to be printed. After being inked, the image is transferred (or offset) from the plate to a rubber “blanket” and then onto the substrate. Extra maintenance is frequently required to ensure plate quality; plates are prone to oxidation if not properly cared for.

5. Rotogravure Printing Machines

Gravure image carriers are typically much more expensive than Flexo, requiring a much higher number of prints to break even. Gravure lead time is typically 3-4 times that of Flexo in terms of image carrier manufacturing time. One of the reasons gravure is best suited for high-detail printing on applications such as magazine covers is because of this.

Industrial Printing Machines | Speak With the Pros

Understanding the basics of different printing machines and methods is essential whether you’re looking to invest in a printing operation or find a print house to partner with. Consult the experts with over 100 years of printing industry experience for flexographic operations and image carrier questions.

Read next about four ways laser engraving improves flexo print quality and efficiency