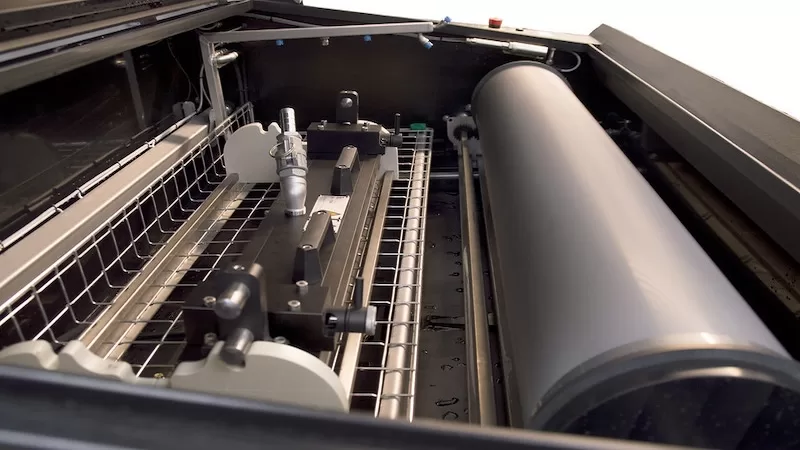

Flexo printing and coating is a liquid application process. This process requires precise control of the amount of ink applied to the substrate so that the end product meets the quality requirements of the customer. The anilox roller is a vital component of flexography and so it is important to understand its calibration.

Test

With laser-etched ceramics, cell-infested paper can be engraved quickly, dried, and ready to print in just a few minutes. The process is so quick that the rolls are etched, dried, and ready to print in just a few minutes.

How often should I calibrate my anilox roll

An anilox should be monitored monthly for flexo printers to ensure consistent printing.

Having accurate control over the ink flow rate is important when printers must monitor the anilox on a monthly basis.

This control should be fully utilized by print shops to increase the productivity of their presses.

To reduce downtime and increase productivity without compromising quality standards in the industry.

Method of calibrating the anilox roller

Print shop owners can now measure the quality of their printing, including the amount of ink and water they use, with the latest advances in software and hardware. By using the right software, they can also accurately measure how much ink or water they use in a month. After connecting the software to the printer’s anilox system, it can automatically adjust the flow rate of ink and water. Consequently, the press produces a more durable and less prone to failure output.

On the other end printers are capable of monitoring their anilox rolls for wear and tear, as well as their consumables, which can have a positive effect on both productivity and output print quality.

Benefits of calibrating the anilox roller

Your end goal should be to keep your presses running longer, and to lessen the impact of any downtime or slowing of the press.

It’s no surprise that so many printers have issues with their anilox roll, as they tend to wear out easily.

The calibration of the anilox roller is required to achieve quality results. Proper calibration of your plate-to-anilox system is important. A small error could lead to a costly mistake.

These problems usually include: slow press runs, double bumps, expensive setup times, the need for high toner inks, and issues with print fidelity.