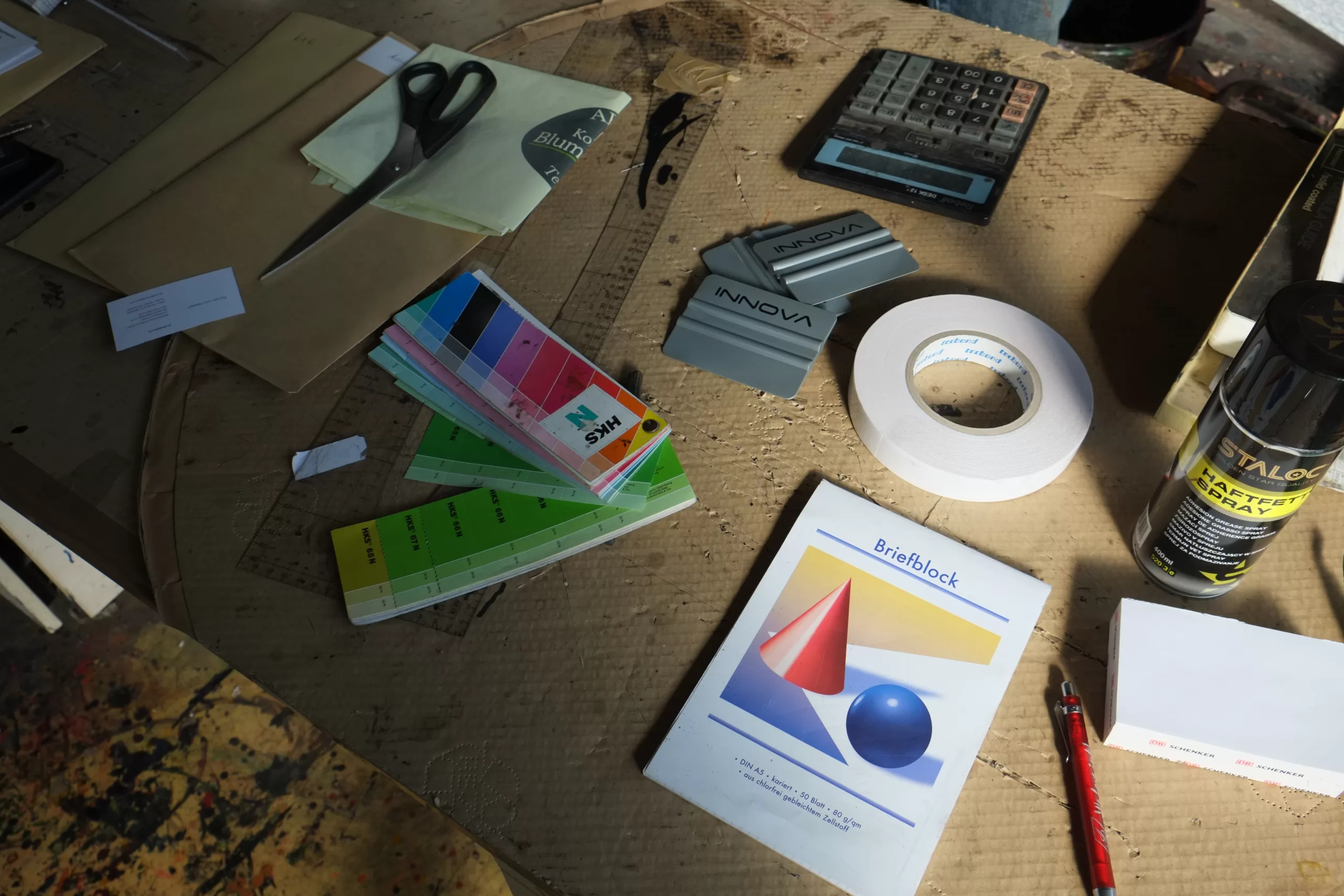

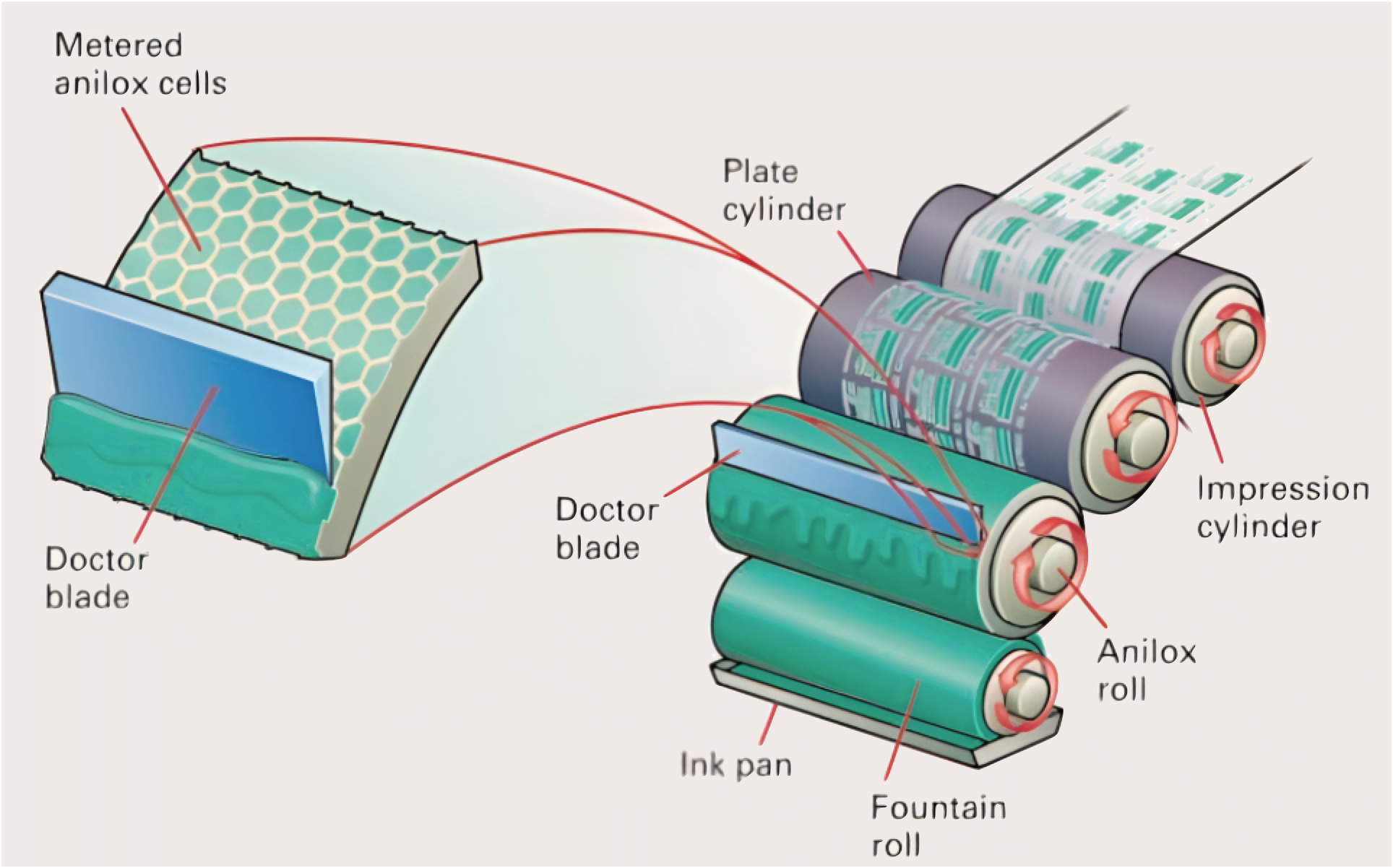

Welcome to an instructive session from the Anyflexo series. We delve into technical nuances of how to mount post-print flexo plates. Our aim is to unveil strategies that elevate efficiency using innovative yet simple tools. Today, we navigate pioneering techniques. These promise not just cost and weight reduction of flexo plates but also enhancement in print quality.

Flexo plates, the canvas for vibrant designs, grow in size, weight, and cost with design scale. Modern printing arsenal is equipped with methodologies. These promise to alleviate such burdens without compromising final print fidelity.

A pivotal facet of this approach is the selection of plate thickness. Traditionally, a plate thickness of 4.32 mm (0.17 in) was the norm. Substituting this with a thinner variant, a 2.84 mm (0.11 in) plate, halves the mass. This presents the first stride towards efficiency and cost-effectiveness.

Elaborating further, to meet the machine undercut’s total thickness, we recommend a pre-laminated cushion foam, 1.5 mm (0.06 in). This is not merely a replacement but a strategic enhancement. In contrast to initial construction, the recommended setup integrates the cushion foam. It achieves comparable results while securing substantial savings in cost and weight.

This recalibration of plate construction carries several formidable advantages.

Notably, the revised setup is lighter and more cost-efficient. It facilitates ease of handling, enabling single operator management. Traditionally, dual personnel were required. More significantly, this configuration introduces shock absorption into the printing system. This plays a crucial role in ensuring superior ink lay-down, elevating print quality, and mitigates board damage risk.

Advancements in foam technology further sweeten the proposition. An additional non-woven surface is incorporated into the mix. This innovation goes beyond weight and cost reduction. It enhances operational dynamics during mounting, particularly in repositioning large plates. This makes it swift and less cumbersome.

In Conclusion

The journey towards optimised post-print flexography doesn’t solely reside in artistic innovation. It equally resides in technological and procedural enhancements. The integration of thinner plates and advanced cushioning foams marks a leap. It achieves high-quality prints in a more efficient, cost-effective, and operationally seamless manner.

We hope this tutorial of how to mount post-print flexo plates sheds light on pragmatic approaches to refining your flexo processes. Thank you for affording us your time in exploring these methodologies. We eagerly anticipate accompanying you in your future printing endeavours.