What are heating rollers used for?

Why do you need heating rollers and what are they? A heating roller is a cylinder or roller that can be kept at a constant temperature for the uniform application of liquid materials. Tempering is very useful when applying a liquid and highly viscous material in processes such as laminating. But what is an electric heating roller?

Familiarise yourself with INOMETA electric heating rollers

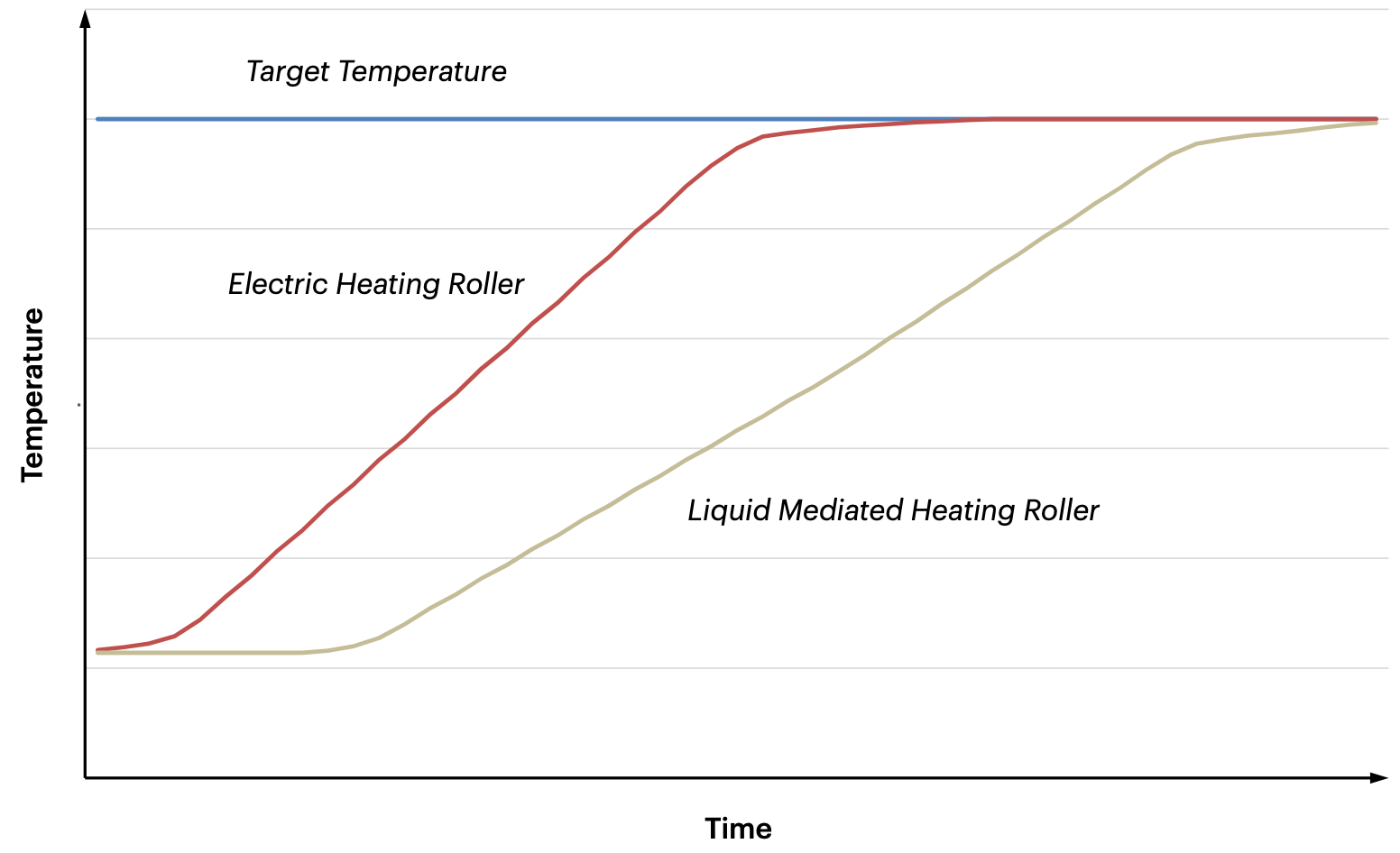

The rollers are conventionally permanently supplied with a warm medium. This can lead to various challenges in the process. As an alternative, there are electric heating rollers such as the innovative heating roller from INOMETA. It is a breakthrough in the heat treatment of materials, especially in the casing and lamination of films and other web-shaped substrates.

Stabler Temperature

These heating rollers are specially designed to ensure a constant, homogeneous surface temperature. Homogeneous temperature distribution is essential for uniform web temperature control. The INOMETA electric heating roller has a fast ramp-up curve of heating power. This allows precise control of the temperature distribution over its surface.

© INOMETA

© INOMETAHigher Efficiency

A key advantage of the INOMETA heating roller is its electrical functionality, which makes the use of liquid media unnecessary. This leads to a number of advantages over traditional heating rollers that work with liquid media. These advantages include high energy efficiency and very good overall efficiency, as no heat is lost in the processing and supply periphery.

Less Space Required

In addition, the INOMETA heating roller requires very little space and requires little investment, as there is no need for storage containers, pipes and pumps. This also leads to very low service costs and shorter service downtimes, which further increases the economic efficiency of the heating roller.

More Friendly to the Environment

The INOMETA heating rollers are also advantageous in terms of environmental friendliness and sustainability. By avoiding oil-based heating media, recycling becomes more environmentally friendly and there is no waste oil pollution. In addition, the electric heating roller does not have any leaks that could contaminate the environment or the substrate.

Wider Application

Heating rollers are used in a variety of industries, including battery and fuel cell manufacturing, as well as calendering, laminating, casing, stretching and elongating processes.

More Flexible Customisation

The materials used for the heating rollers include steel and aluminium, and the surfaces can be customised with different geometries and coatings such as hard metal, non-stick coatings or elastic coatings in different hardness levels.

Conclusion

INOMETA’s commitment to innovation and efficiency is reflected in this heating roller, which not only reduces operating costs, but also protects the environment and improves process quality. It is a technology that could significantly shape the future of web temperature control.

For more information, please contact INOMETA by leaving a message or sending us your detailed business requirements.