Effectively managing colours in flexographic printing pose distinct challenges due to varied substrates, non-standard ink hues, and unique dot gain attributes. Colour Management Systems (CMS), such as Agfa ColorTune 3.0, play a pivotal role in maintaining colour consistency across diverse input and output devices, aligning printed outcomes with originals. These systems support colour communication by harmonising colours on screens and proofing tools with the expected or actual printing press results. Recognising that a monitor’s gamut surpasses a press’s ink range, designers need a comprehensive grasp of the printable colour spectrum available on their computers.

Determining this range involves executing CMS tests on the flexographic printing press under controlled conditions using identical inks, plates, mounting tape, and anilox rollers from the production run. Since different substrates affect colours in varied ways, each new material necessitates a new test. The outcomes of these tests are input into the CMS software to establish calibration tables and develop press profiles. The CMS then adjusts digital cameras, scanners, monitors, and proofing tools based on the colours printed by the specific press. Input devices like cameras and scanners, as well as prepress output tools such as monitors and proofing systems, are aligned with the anticipated press results.

Test Targets in Flexo Colour Management

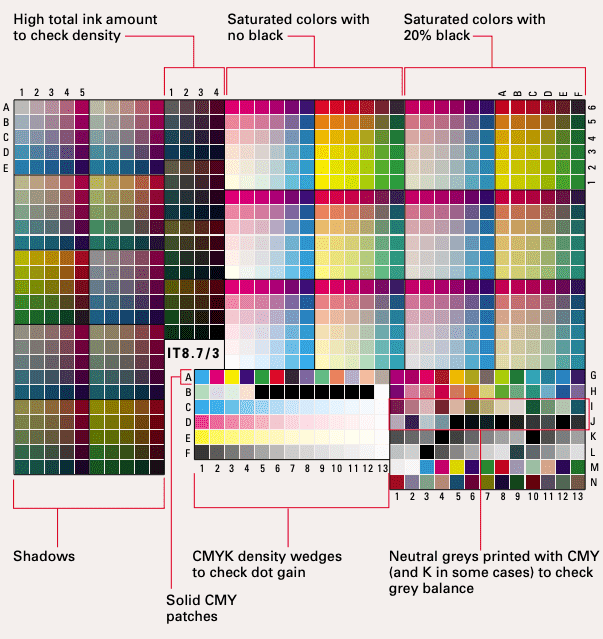

Colour Management Systems construct profiles by examining standard colour data from test targets like the IT8 series. These targets aid in calibrating prepress input devices (e.g. scanners), output devices (e.g. proofing tools), monitors, and the press itself. While IT8 7/1 serves as a reflective colour target for calibrating scanners in a colour management system, IT8 7/2 and IT8 7/3 fulfil different calibration purposes.

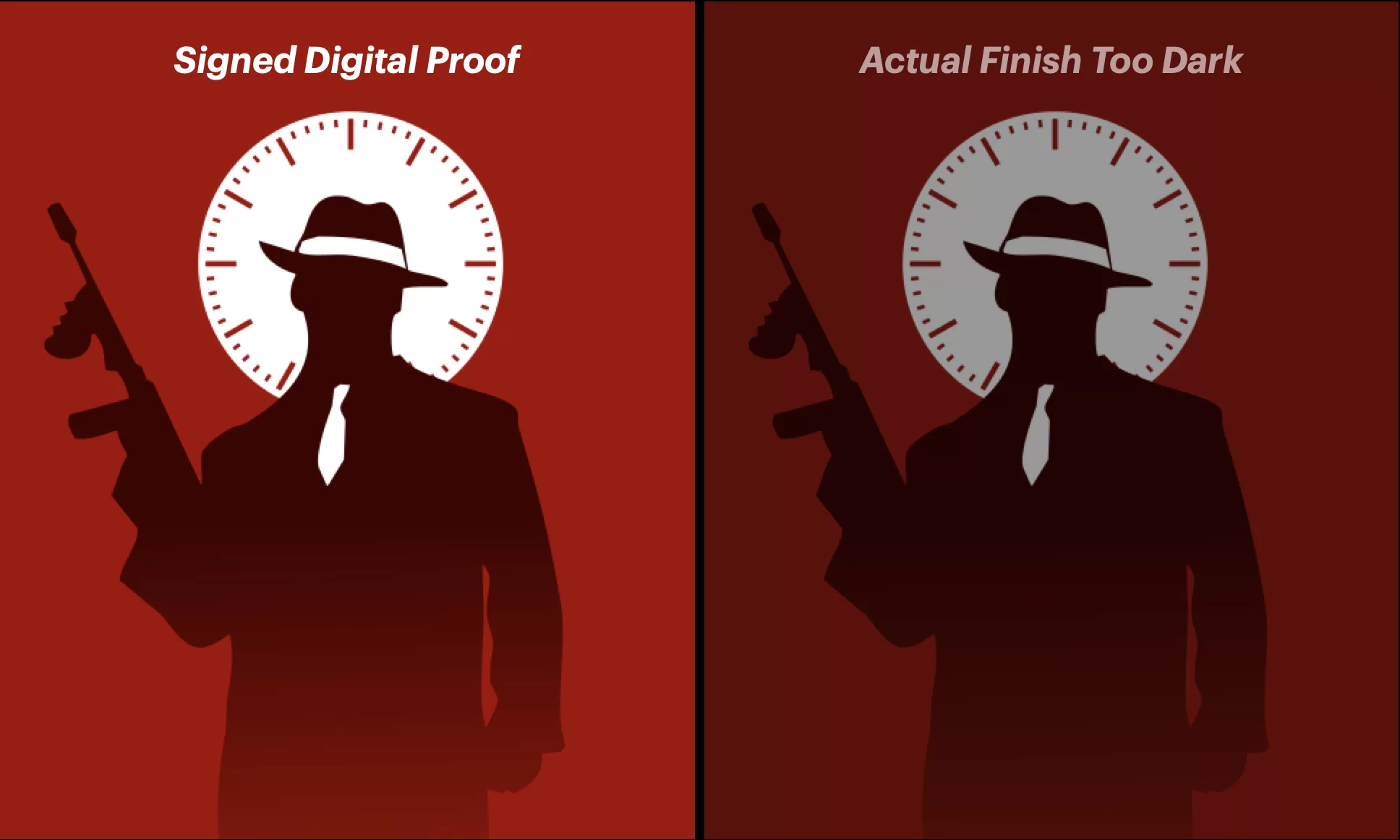

To create a press profile, the imagesetter undergoes calibration, producing IT8 7/3 data onto film. Subsequently, plates are generated and mounted before printing the IT8 7/3 under real production conditions. Samples are measured for density, dot gain, and colour values, and the resulting data is fed into the CMS. This allows the CMS to readjust monitors, digital proofing tools, and imagesetters to align with the expected press output.

© AGFA

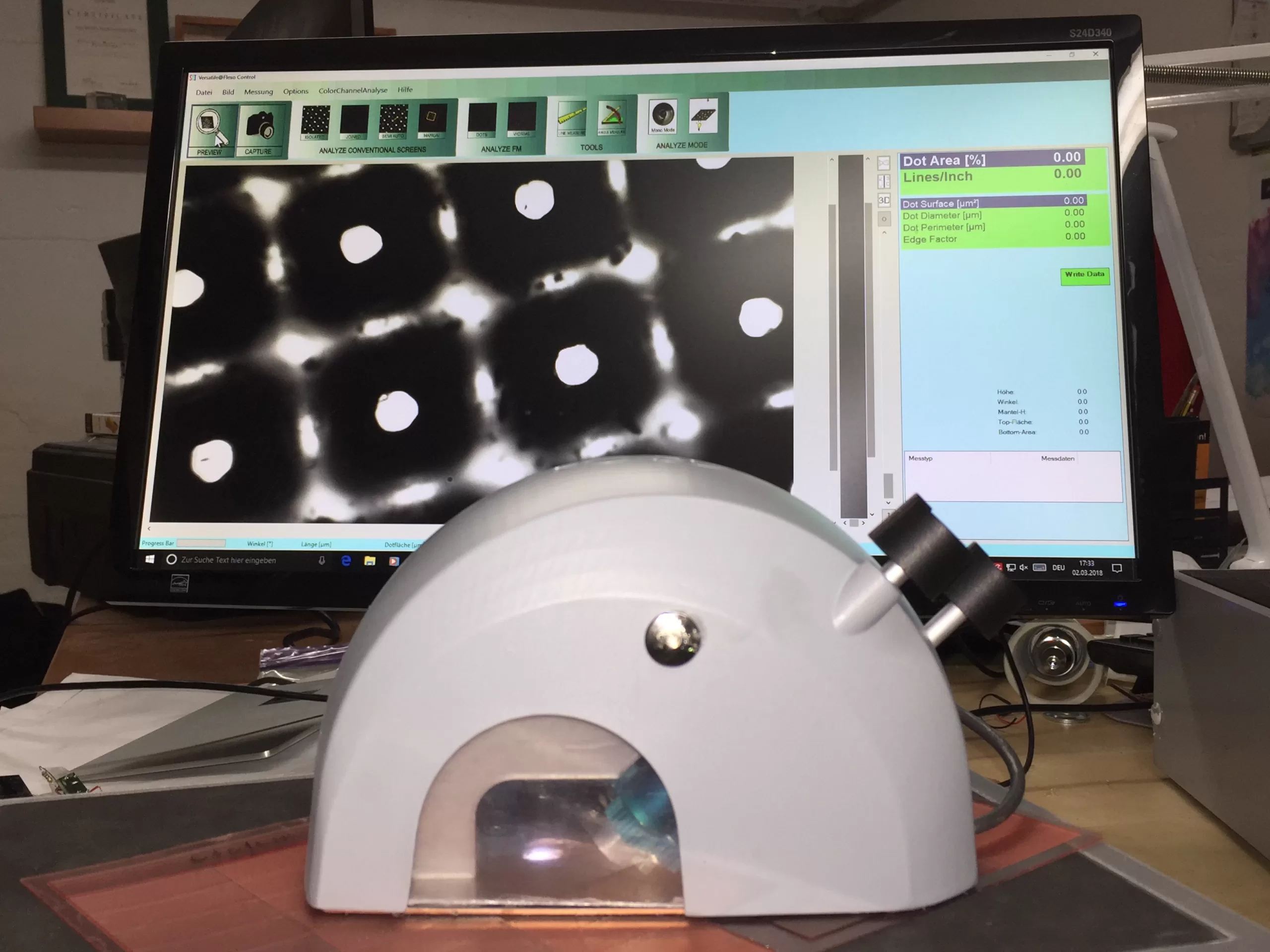

© AGFAFlexographers have access to various colour measurement tools to analyse printed samples. The reflection densitometer gauges solid ink density, while the colorimeter and spectrophotometer evaluate hues in spot colours or CMYK combinations.

Screening in the Lens of Flexo Colour Management

Artwork files progress to plate imaging with RIP curves applied for dot gain compensation, utilising characterisation data for output uniformity. Although not solely centred on colour, the dot structures during platemaking significantly impact visual prints, especially in highlight areas. The selection of optimal screening algorithms, particularly in highlight zones, is crucial for achieving desired print outcomes.

It is true that FM or hybrid screening systems have been gaining popularity. However, proven AM screening stands as a reliable choice in platemaking and printing stages, fostering maximum consistency and repeatability. By embracing statistical methodologies for characterisation data during fingerprinting, a representative and substantial dataset is obtained, anchoring pre-press edits and proofs on dependable measurements.

In Conclusion

Effective colour management in flexographic printing is vital for consistent and accurate results. Leveraging advanced systems and precise calibration ensures accurate colour reproduction across substrates and printing conditions. Understanding colour profiles, test targets, and screening methods helps navigate challenges like varied substrates and dot gain. By optimising press profiles and selecting screening algorithms carefully, printers can enhance colour fidelity and streamline workflows. Embracing technology and industry trends while honing colour management skills elevates print quality and client satisfaction. Mastering colour management is not just technical; it’s a creative journey to transform visions into impactful prints.