Choose the correct flexo end seals for your application to achieve proper doctor blade seating. If used correctly, these low-cost consumables can save printers thousands of dollars in waste and downtime. The job of the end seals is to keep the coating or ink from leaking out of the chamber’s ends.

Problems Caused by Failed Flexo End Seals

- Chamber leaks and mess

- The poor graphic quality and ink/coating waste

- Excessive doctor blade wear

- Premature anilox roller wear and scoring

- Press downtime

Why Do Chamber Leaks Happen?

While there are other causes of chamber leaks, failed end seals account for the majority of them. Enlist the assistance of your end seal supplier to resolve these issues and ensure that you are using the appropriate end seals for your application.

When a chamber leaks, a press operator will frequently try to solve the problem by increasing the load pressure rather than looking for the source of the leak. The doctor blade should be subjected to some upward pressure to form an adequate seal, but not so much that it requires additional loading pressure to make contact with the anilox roller in the blade’s centre.

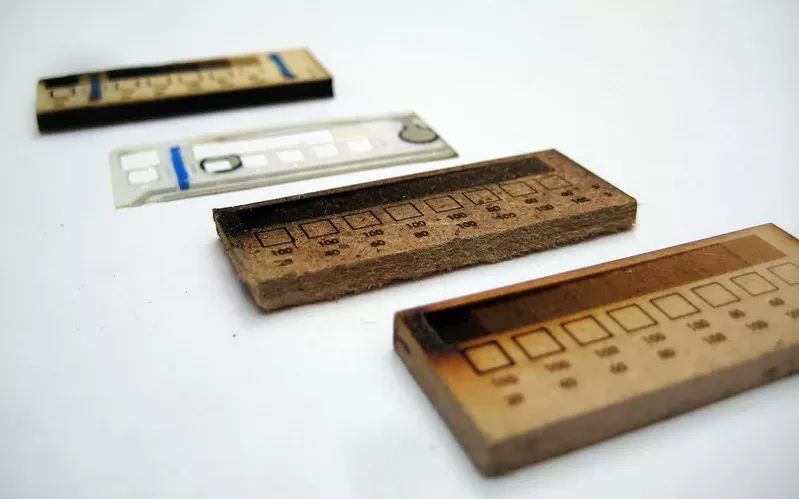

Materials for Chamber System End Seals

End seal materials vary in terms of abrasion resistance, durability, and solvent resistance. Again, your end seal supplier can assist you in determining the best material for your application:

- Foam seals are the most common and least expensive. The density of the material can also vary significantly, ranging from extremely firm to more malleable.

- Neoprene or rubber seals provide a longer service life than foam seals because they are compatible with aqueous and UV coatings and inks, they do not need to be changed between jobs. However, due to the coefficient of friction between the material and the anilox roller surface, these seals do not seat well.

- Pre-soaked felt end seals are a better option for repairing leaks. After flushing the system, apply seal grease to the radius portion of the seals to ensure a tight fit and to extend the life of the seals by reducing friction.

Final Thoughts on Flexo End Seals

Choosing the right seal material and design for your application, as well as replacing end seals as needed, will help ensure that inks and coatings do not leak out of the chamber. End seals, despite their low cost, have the potential to save thousands of dollars in waste and downtime.