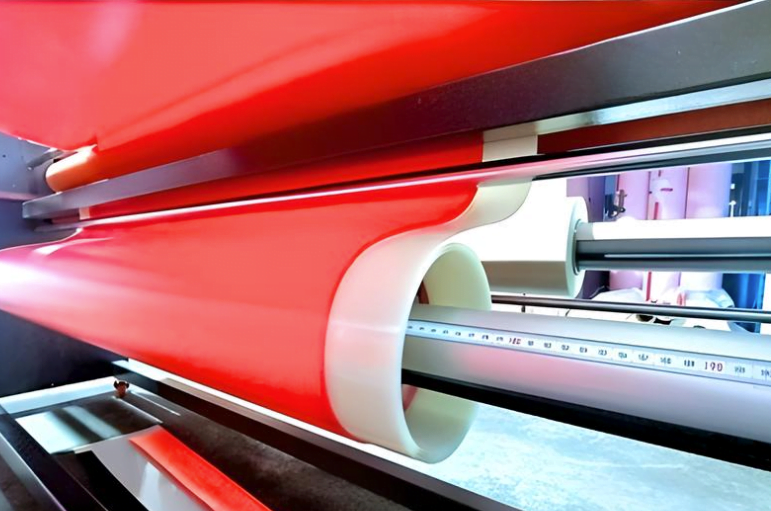

Flexo printing technology, considered the future of printing, offers a wide range of features and benefits to meet a variety of customer needs. The technology is widely used to produce items such as posters, labels and packaging. Cost-effective and versatile, flexo printers are ideal for small businesses and entrepreneurs seeking quality printing solutions. To run a successful printing business, an excellent flexo printing machine operator would be indispensable.

Responsibilities of a Flexo Printing Machine Operator

A flexo machine operator holds numerous responsibilities. They must efficiently and swiftly operate the machine to ensure high-quality prints. Monitoring the work area vigilantly to ensure smooth operations is essential.

Part of the operator’s duties involves running the press to generate finished products. They must possess exceptional attention to detail, adeptness at multitasking, strong manual dexterity, and superb eye-hand coordination. Troubleshooting skills and the ability to interpret blueprints are crucial.

Skill Kit Essential for a Flexo Printing Machine Operator

Flexo printing machines offer a significant advantage by producing top-quality prints rapidly and efficiently, thus minimising printing time. Operators utilise their expertise in printing techniques and equipment to meet customers’ specific requirements, enabling them to achieve more in less time, garnering customer satisfaction.

To operate flexo machines effectively, most operators need comprehensive training, involving equipment setup, operation, and understanding machine capabilities. Trained operators are adept at handling machines with reduced risk of injury and delivering satisfactory results, enhancing customer contentment.

A proficient flexo machine operator should comprehensively understand the printing process, printer mechanics, and printing press operations. Precision, hand-eye coordination, print layout interpretation, and adeptness at machine adjustments are vital skills. Typically, a minimum of two years of production experience is required for flexo machine operators.

Physically, a flexo printing machine operator should encompass superb manual dexterity, excellent vision, robust back and arm muscles, and exceptional hand-eye coordination.

Challenges Faced by a Flexo Press Operator

Operators encounter various challenges when working with flexo machines, particularly in maintaining machine efficiency and ensuring print quality. Precision and accuracy are paramount due to the demand for high-quality prints, necessitating a deep understanding of machine mechanics and operational proficiency.

Income and Benefits for a Flexo Press Operator

Flexo machine operators are usually remunerated based on their production output, benefiting from the machines’ rapid and efficient operation, allowing mass print production in minimal time. The machines often feature advanced capabilities like paper type recognition and adjustable print speeds, ensuring accurate printing. Benefits for operators often include competitive pay, flexible working hours, healthcare coverage, and retirement savings plans.

In Summary

A flexo machine operator plays a pivotal role in operating flexo machines safely and efficiently. Equipped with knowledge of machine mechanics and print specifications interpretation, they ensure rapid and accurate machine operation for top-tier print production, fostering a rewarding career path.