Flexo printing is a widely used printing process for producing high-quality prints. While it may seem simple, precise adherence to specific steps is crucial in order to achieve accurate results. This article aims to comprehensively guide you through the fundamental steps of the flexo printing process in a cohesive manner.

Understanding the Basic Steps of Flexo Printing Process with Comprehensive Guide

The first step in flexo printing is to create a test sheet using a different material than the final product. This allows for quality checks before moving on to the main printing process. Once any potential issues are resolved, the printer proceeds with the main process.

In the main printing process, multiple layers of ink are laid down on top of each other. An image is printed one layer at a time, ensuring that they are overlaid without any gaps. This meticulous process enables precise and high-quality printing, which is essential for advertisements and labels.

Flexo printing utilises materials like paper or fabric to create printed products. The main steps involved include depositing the print material, applying heat and pressure, and finally removing the print material. Its speed and accuracy make it ideal for high-volume manufacturing, while its low environmental impact makes it a sustainable option.

Three Major Stages of Flexo Printing Process with Comprehensive Guide

Flexo printing can be divided into three main stages: pre-press, on-press, and post-press. Each stage has its own set of procedures to follow.

1. Pre-Press

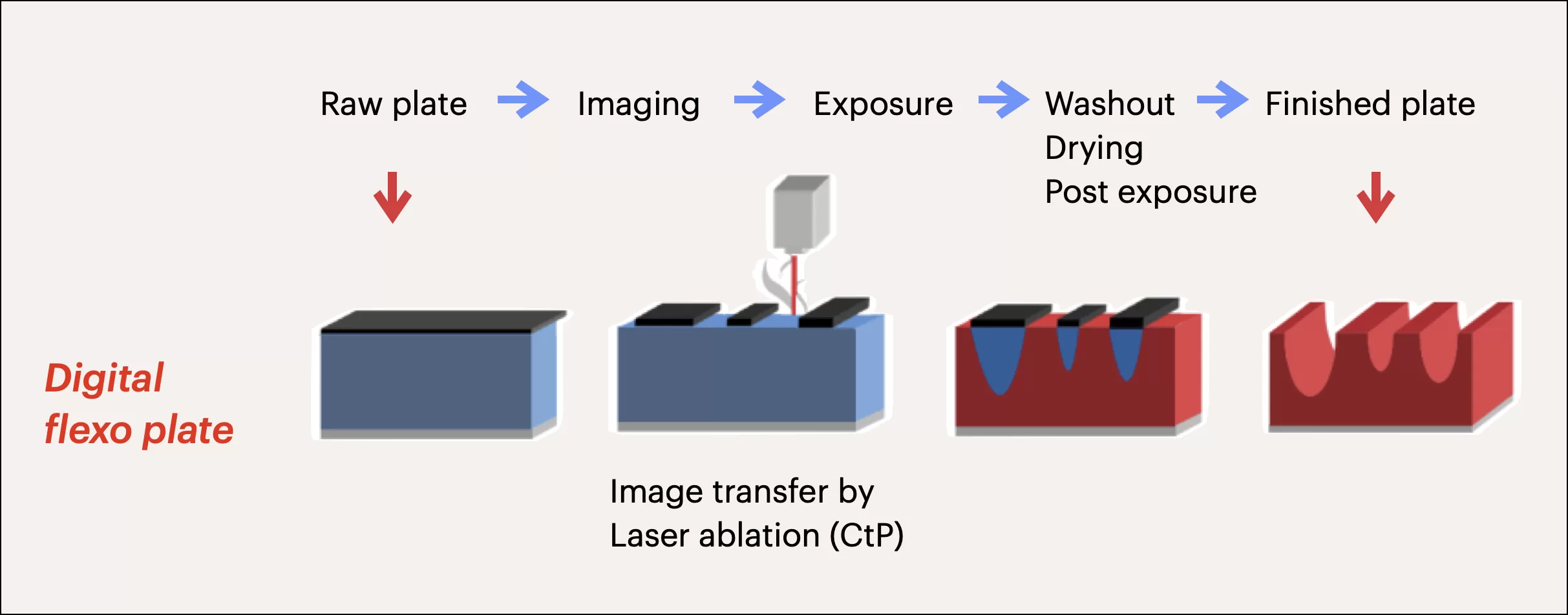

In the pre-press stage, computer-generated artwork or an outline is created as a guide for printing. This artwork is used to determine ink usage and placement. The graphic artist sends the artwork to the flexible plate production department. Once the plates are created, they are sent to the press along with a pre-printed sample to ensure accuracy. Attention to detail during the design phase is crucial for producing high-quality flexo prints.

2. On-Press

Once the plates and pre-printed artwork are received at the printing press, a supervisor assigns the job to a specific machine. The pressman or machine operator then prepares the machine and colours to match the requirements. They ensure that all necessary plates, raw materials, cylinders, dies, and colours are available. The plates, dies, and colours are mounted on the machine, which is equipped with the appropriate raw material. The operator carefully sets up the machine to ensure correct printing and die cutting. After printing, a thorough inspection is conducted to verify that the results align with the artwork/sample provided. This process, known as making ready, ensures optimal printing quality.

3. Post-Press

In the post-press stage, materials received from the printing department are converted into the required quantity and rolled up. They are then packaged in cartons and sent to the quality department for inspection before being dispatched. Cutting systems, which are usually more advanced than printing presses, are utilised to cut labels, tags, or other flexo products. These systems are particularly suited for small-scale production runs.

Getting the Best Results in Flexo Printing

To achieve optimal results in flexo printing, consider the following tips:

- Ensure your images are properly sized: The size of your image will affect the final print size, so it’s essential to use the correct dimensions.

- Use a high-quality printer: Investing in a good printer will yield better prints and prove worthwhile in the long run.

- Employ flexo printing techniques: Experiment with techniques like embossing or recessing text to achieve desired effects.

FAQs about the Flexo Printing Process

Q: How is the press step used to print flexo images?

A: Flexo printing involves applying pressure to a print plate using a press, resulting in the image being printed onto the paper. This method works for both positive and negative images. Flexo printers are commonly used in various publications, as well as for creating art prints and posters.

Q: What makes flexo printing so efficient?

A: Flexo printing is highly efficient due to its process of applying the image directly to a flexible sheet of paper. The printhead moves across the sheet, applying the image to each section as it passes. This eliminates the need to transfer the image to a hard surface before printing. Flexo printing offers advantages such as the ability to print on various materials and high precision due to the printhead’s accuracy.

In Conclusion

Flexo printing technology offers numerous benefits for businesses, including faster turnaround times and improved print quality. With its versatility and efficiency, flexo printing has become the standard in the print production industry. If you’re looking to enhance your business operations, incorporating flexo printing is a valuable proposition.

![[Flexo Flaw Fixing] Low Ink Adhesion](https://flexopedia.net/wp-content/uploads/2022/07/Adhesion_Tape_Test.png)