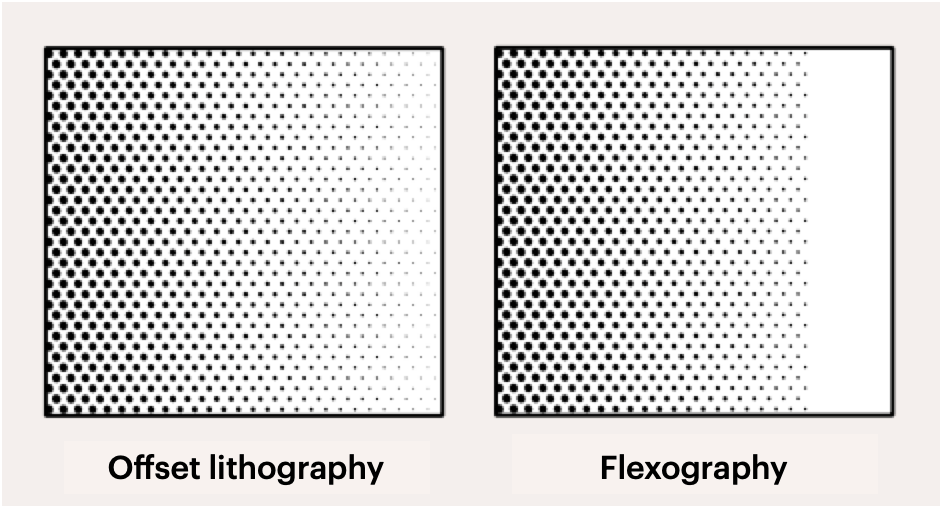

The use of flexography is growing in popularity in today’s printing markets, where short run, low-cost, and high-quality are crucial to success.

The flexography market is today on the rise but at the core when you look at the development of flexography, it reveals a printing technology and culture that has been willing and capable of change in response to the needs of the packaging industry. An evolutionary process of improvements in materials and equipment, rather than a single discovery, has led to flexography as it is known today. The first use of soft compressible plates can be traced back to the late 1880s, when letterpress printers needed to find a way to print kraft paper grocery bags and corrugated boxes. The materials were rough in texture, and did not respond well to the ink transfer pressure of hard letterpress plates. To solve the problem, printers began creating plates from rubber, rather than from wood or lead. This quickly became the dominant method for printing corrugated, and also grew steadily in the bag printing industry.

In 1914, the Interstate Commerce Commission approved the corrugated box as a shipping container, a decision that began a new growth period for flexography. Clear Packaging In the early-to-mid 1920’s, flexographic printers responded quickly to the introduction of cellophane as a clear packaging material. White inks were developed, drying systems were improved for cellophane’s non-absorbent surface, and press tension systems were refined to handle its caliber and weight. Approximately ten years later, polyethylene was introduced, and went on to become the most commonly used material for clear, flexible packaging.

The use of the flexographic process has continued to grow in all packaging markets, including those that have traditionally used gravure and lithographic methods.

Corrugated

© AGFA

© AGFABy far the largest market for flexography, corrugated is printed on sheet-fed presses Fast drying water-based inks, the soft, conforming plate, and light impression pressure make flexography well suited for printing corrugated boxes in large quantities.

Flexible Packaging

© AGFA

© AGFAMost flexible packaging uses non-absorbent polymer film, including bread bags, snack food bags, candy wrappers, pouches, and textile wrap.

Gift Wrap and Wallpaper

© AGFA

© AGFAA continuous repeat allows the printing of products such as wallpaper and gift wrap. Design rolls, which do not have a plate seam, are used to print a continuous background colour.

Folding Cartons

© AGFA

© AGFAAlthough folding cartons, including cereal, detergent, and cosmetic boxes, are printed by both the lithographic and gravure processes, flexography has recently increased its market share due to improved quality.

Rigid Paper Boxes

© AGFA

© AGFARigid paper boxes, or pre-formed boxes are used for bakery products, shoes, and neckties.

Envelopes

© AGFA

© AGFAFlexography is used to print many kinds of envelopes, including those for direct mail, sweepstakes, general mailing, and overnight delivery. The security printing on the inside of many envelopes is often applied by flexography.

Paper Grocery Bags

© AGFA

© AGFAThe paper bag is the original flexographic product. In the late 1800’s flexography evolved from the need to apply graphics to plain brown grocery sacks. The evolution continues today.

Plastic Bags

© AGFA

© AGFAFlexography can add advertising and graphics to plastic bags that are carried by customers in stores.

Newspapers

© AGFA

© AGFAIn the US alone, there are between 35 and 40 newspapers using the flexographic printing process for the entire paper. Many newspapers use flexography to print the Sunday comics.

Tags and Labels

© AGFA

© AGFAThe fast drying fluid inks used by flexographers allow inline die cutting immediately after printing. The quality of many flexographic labels is equal to or better than that offered by lithography or gravure.

Pre-printed Liner-board

© AGFA

© AGFAPre-printing liner-board allows high-quality graphics to be placed on corrugated containers.

Today the process continues to adapt. As the technology is refined, quality continues to increase, making flexography the leader in packaging graphics applications.