Buying a flexo press is a lot like buying a car. Finding the right balance between safety, functionality, quality and budget is essential. Investing in a flexo press is a big decision, but there’s no need to worry. With the right knowledge, you will be optimising your presses in no time. This guide will walk you through key considerations to help you make an informed decision to choose the right flexo printing press.

Finding the Perfect Machine for Every Material

The first factor to consider is the type of substrate you will be printing on. Flexo printing can be used on a variety of materials, including

- Foil and film

- Tissue and non-wovens

- Corrugated material

- Blister packaging

Not all presses are compatible with all substrates, so it is important to choose wisely. Even if you are not currently printing on these materials, consider whether the press you are considering can handle them. Future-proofing your investment allows for potential product line expansions down the road.

Top Tips for Selecting Your Next Flexo Press

When researching flexo presses, keep the following four main criteria in mind:

- Operation

- Functionality

- Quality

- Cost.

Understanding the Operation

Make sure your business is ready for the new machine. Consider whether you will need a larger workspace to accommodate it. Will you train existing employees or hire new ones?

Evaluate how the new machine will fit into your manufacturing process. Will it speed up your current operations? Will you have to adjust your workflow? These considerations can have a significant impact on setup costs and overall efficiency.

The Ultimate Guide to Functionality

Flexographic presses can be equipped with a variety of options to increase functionality. Depending on your company’s current and future needs, you may want to consider machines with

- Conveyor systems

- Extra drying systems

- Web cleaners

- Automated inking systems.

Think about your business needs years from now. Investing in additional features now can make your printing process more efficient and cost-effective in the long run.

Achieve High-Quality Prints

When making a significant investment, it is important to prioritise quality equipment. Buy a machine from a well-known, reputable manufacturer to ensure reliability and performance. Companies like Mark Andy, Nilpeter, and MPS are known for quality machines and solid warranties.

Balancing Quality and Cost

Cost is an important factor in any purchasing decision. While you don’t want to overspend, remember that with flexo presses, you get what you pay for. Avoid the temptation to save money by buying a machine with fewer features or from an unknown manufacturer, as these can lead to malfunctions or lack of warranties.

It’s best to purchase new equipment and work with the seller to find financing options that maintain functionality and quality standards.

Increase Productivity with Peripheral Equipment

Once you have your flexo press, you may want to consider peripheral equipment to increase efficiency. For example:

- Elastomer Sleeves: Increase efficiency by reducing setup time and waste. These durable, flexible sleeves can last up to three times longer than other materials and improve reliability with solvent-based inks.

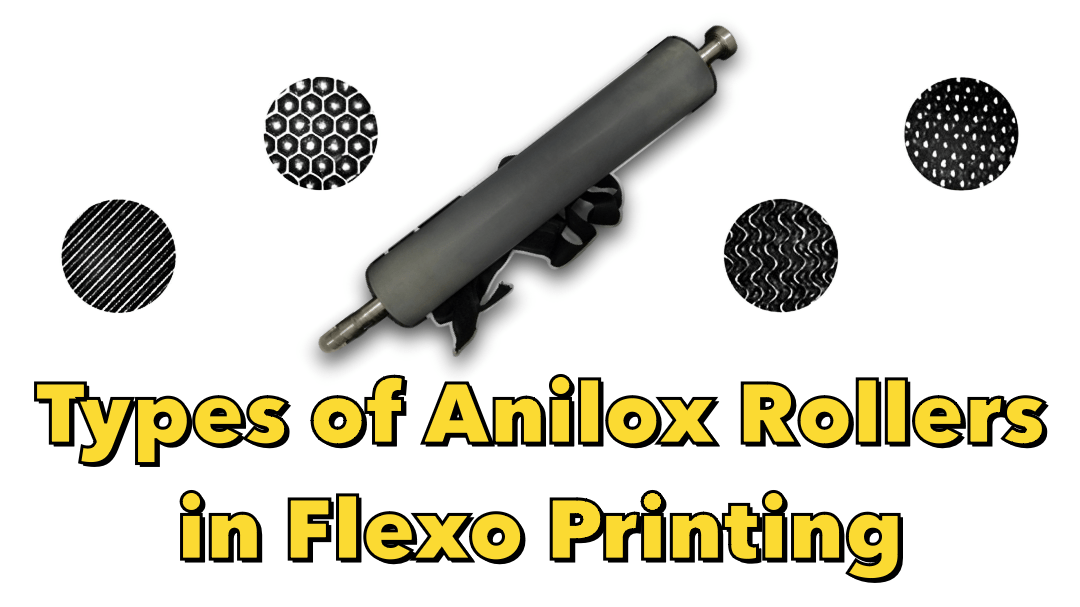

- Custom Anilox Rollers and Flexo Inks: Depending on your printing needs, custom anilox rollers and inks can improve print quality.

- Prepress Solutions: Expert assistance with graphic design, colour management, and print prototyping can help reduce waste and turnaround time.

Elevate your Printing Game

When you choose the right flexo printing press, the research phase can be time-consuming, but it’s well worth the effort. Don’t rush into this important decision because the right flexo press can have a significant impact on your business. By following these guidelines, you can find a flexo press that will serve your business well for years to come.