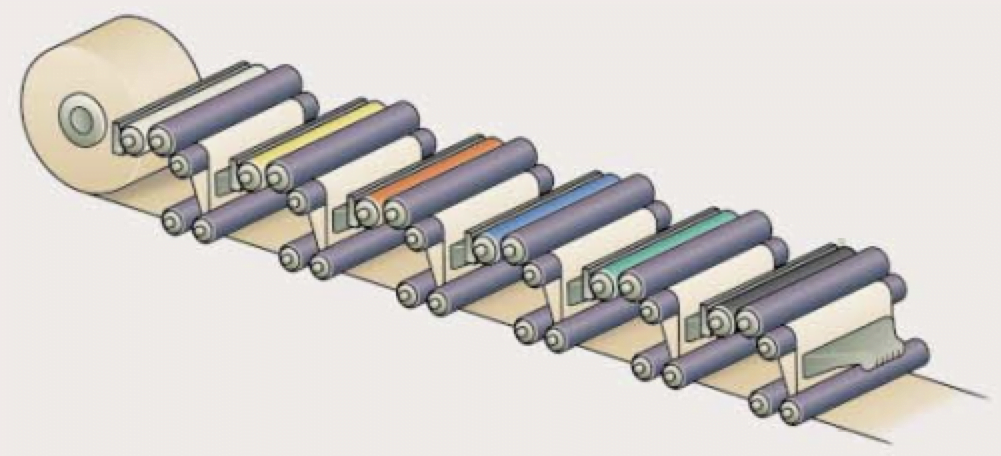

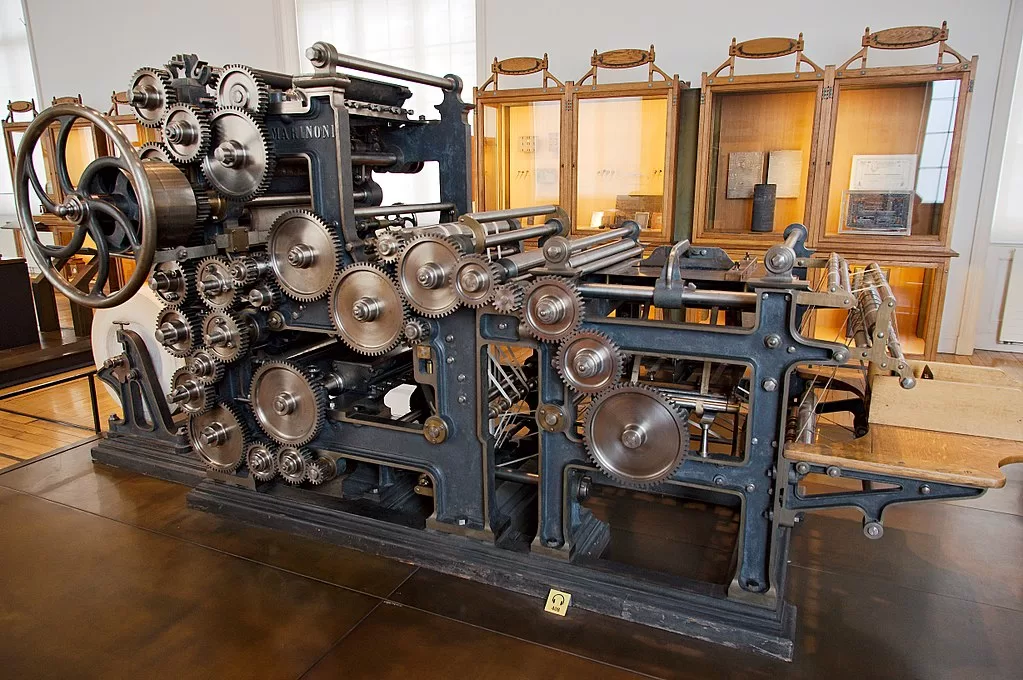

Different styles and types of printing presses exist to serve the diverse flexographic printing industry, with a wide range of substrate materials and sizes, as well as a plethora of different applications. To maximize the potential of your artwork and ensure that your printer’s inline press is capable of handling the design of your next product packaging, poster, or other goods, it’s critical to understand the components/sections of an in-line press and how they work together.

Dismantling an In-Line Printing Press

An inline flexographic press is divided into six major sections:

- Unwind and Infeed

- Enclosed Doctor Blade Inking System

- Inking Anilox Roller

- Image Carrier and Impression Cylinder

- Dryer

- Outfeed and rewind

These six components work together to form a seamless printing system capable of handling large runs on a variety of substrates. Each section is critical to the production of printed goods.

- Unwind and Infeed: The substrate is fed into the printing press on a roll.

- Enclosed Doctor Blade Inking System: The enclosed chamber is filled with ink by a continuous cycling pump. Ink flows in and out of the enclosed system during printing.

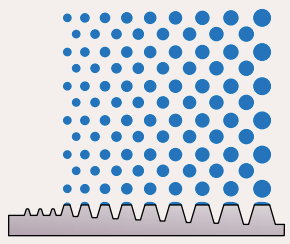

- Inking Anilox Roller: Microscopic cells in the anilox roller transport a thin layer of ink from the inking system to the image carrier.

- Image Carrier and Impression Cylinder: The image carrier is responsible for transferring the image to the substrate.

- Dryer: To dry the ink, the substrate passes through roller-less and plate-less sections.

- Outfeed and rewind: The outfeed and rewind step on a flexographic printing press are where a substrate is rolled up again in preparation for a cutting die that will separate individual prints.

Image Carrier Services | Inline Flexographic Printing Machines

The image carrier is a critical component of any flexographic printing press. The process of creating an image carrier varies depending on customer requirements such as elastomer selection, adhesive requirements, dimensional considerations, and more — however, the majority of image carrier services take the following steps:

- Receiving / Incoming Inspection

- Base Preparation

- Rubber Wrap

- Autoclave / Vulcanization

- Rough Grind

- Trim

- Finish Grind

- Polishing

- Laser Engraving

- Print Proof

- Final Clean-up

- Final Inspection

- Shipping

Choosing the Best Image Carrier for Flexographic Printing

Identifying the location of a printing defect is one of the most difficult aspects of operating an inline flexo printing press. While image carrier services typically include the production of sleeves, cylinders, and plates, top-tier manufacturers also provide press operators with assistance when defects and challenges arise.