This article is part of the FLEXO FLAW FIXING series

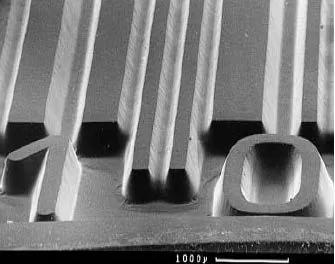

In the world of flexo printing, precision in screen dot quality isn’t just a requirement. It’s the backbone of maintaining high standards and delivering flawless prints. Screen dot inaccuracy can mar the final product in flexo printing, leading to dissatisfaction and potentially significant financial losses. Recognising the causes of these inaccuracies and implementing effective remedies is essential for any flexo printer striving for excellence.

Causes and Remedies of Inaccurate Screen Dots

Ink Debris on Printing Plates

- Cause: As ink dries on the plate, it can cause jagged, uneven edges around the screen dot.

- Remedy: To combat this, regular cleaning of the plate is essential. The following measures can also help prevent premature ink drying. Printers can, for instance, adjust the solvent mix, add retarder, etc. Make sure that the heat blower isn’t blowing directly onto the plate, etc.

Secondary Pollution on Printing Plates

- Cause: The presence of lint particles from the cleaning cloth on the printing plate can affect print quality.

- Remedy: Ensuring that the plate is cleaned with a lint-free cloth or brush can eliminate this source of inaccuracy.

Excessive Pressure Settings

- Cause: A common problem is that the pressure setting between the anilox roller and the plate cylinder and between the plate cylinder and the substrate is too high.

- Remedy: This can be easily remedied by reducing the pressure settings to ensure that the ink transfers smoothly without distorting the screen dots.

Ink Viscosity Problems

- Cause: High ink viscosity is another culprit that can lead to screen dot inaccuracy.

- Remedy: The solution is to adjust the ink viscosity by incorporating solvents, which allows for better ink flow and more accurate dot placement.

Unsuitable Ink Recipe

- Cause: Sometimes the selected ink recipe may not be well suited to the printed image.

- Remedy: In such cases, replacing the ink with a more appropriate option can result in significant improvements in print accuracy.

Incorrect Machine Setup and Operation

- Cause: The foundation of accurate flexo printing is proper machine setup, from configuration and paper selection to data input accuracy.

- Remedy: Ensuring that these elements are carefully checked and adjusted as necessary can drastically reduce screen dot inaccuracies.

Inadequate Staff Training

- Cause: Inadequately trained personnel can contribute to various printing errors.

- Remedy: Investing in comprehensive training for all personnel involved in the printing process ensures that everyone is up to date with the latest techniques and standards, which is critical to maintaining print accuracy.

Conclusion

To maintain optimal print quality and operational efficiency in flexo printing, it is imperative to diagnose and promptly address any problems related to screen dot inaccuracy. Understanding the root causes of these inaccuracies and taking appropriate corrective action not only improves print quality, but also enhances a company’s reputation for excellence in the highly competitive printing industry.

In a field where precision is paramount, a proactive approach to preventing and correcting screen dot inaccuracies can make all the difference.

![[Flexo Flaw Fixing] Screen Dot Inaccuracy](https://flexopedia.net/wp-content/uploads/2022/05/039_Deformed_Dots.png)

![[Flexo Flaw Fixing] Blocking](https://flexopedia.net/wp-content/uploads/2022/05/038_Ink_Blocking-jpg.webp)

![[Flexo Flaw Fixing] Gear Marks](https://flexopedia.net/wp-content/uploads/2022/07/Dirty_Marks-jpg.webp)