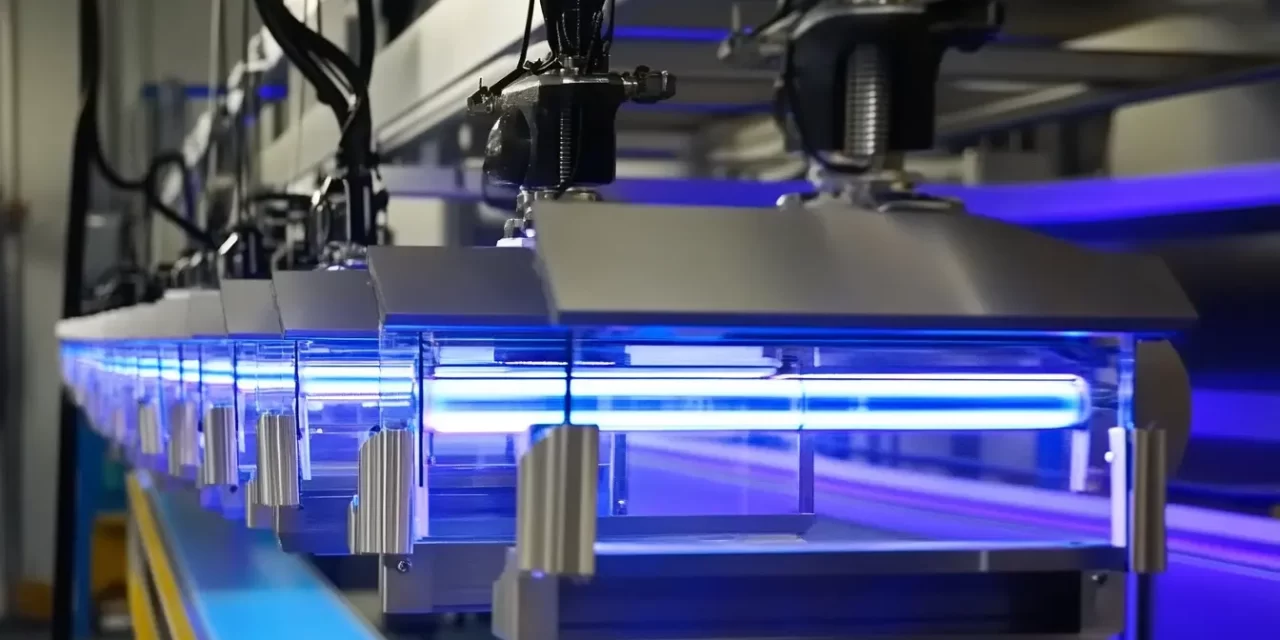

Flexographic printing is renowned for its efficiency and versatility. Yet, one critical component often works behind the scenes to ensure high-quality results: lamp systems. From drying inks to curing coatings, lamp systems play a pivotal role in the success of flexographic printing. In this guide, we’ll dive deep into the technology, functionality, and advancements of lamp systems, helping you make informed decisions for your printing operations.

What Are Lamp Systems in Flexographic Printing?

Lamp systems in flexography refer to specialized light sources used for drying and curing inks, coatings, and adhesives during the printing process. These systems ensure that printed materials dry quickly and evenly, preventing smudging, ink set-off, or incomplete curing.

The most common lamp systems in flexographic printing include:

- UV (Ultraviolet) Lamps

- LED Lamps

- Infrared (IR) Lamps

Each type has its unique advantages and applications, tailored to the demands of different substrates, inks, and production speeds.

Why Are Lamp Systems Essential in Flexographic Printing?

Lamp systems are critical for the following reasons:

- Fast Drying: Flexographic presses operate at high speeds, requiring quick drying to maintain productivity.

- Improved Print Quality: Properly cured inks and coatings result in vibrant, durable prints.

- Energy Efficiency: Modern lamp systems are designed for maximum output with minimal energy consumption.

- Substrate Compatibility: Different substrates—like paper, plastic, or foil—require precise drying or curing to prevent warping or damage.

Without efficient lamp systems, the flexographic process would be prone to delays, inconsistencies, and compromised print results.

Types of Lamp Systems in Flexographic Printing

UV Lamp Systems

UV lamps use ultraviolet light to cure inks, coatings, and adhesives instantly. These systems are popular for their speed and ability to create high-gloss finishes.

Benefits of UV Lamps:

- Instant curing for increased production speeds.

- Enhanced durability of printed materials.

- Suitable for non-porous substrates like plastics and foils.

Limitations:

- Higher initial investment compared to other lamp systems.

- Heat output can impact temperature-sensitive substrates.

LED Lamp Systems

LED lamps are a modern alternative to traditional UV systems, offering energy-efficient curing with lower heat emissions.

Advantages of LED Lamps:

- Longer lifespan compared to traditional UV lamps.

- Energy-efficient, reducing operational costs.

- Minimal heat output, making them ideal for heat-sensitive substrates.

Drawbacks:

- Limited compatibility with certain ink formulations.

- Higher upfront cost for installation.

Infrared (IR) Lamp Systems

IR lamps use heat energy to dry water-based or solvent-based inks. These systems are common in applications where fast drying is required for porous materials.

Pros of IR Lamps:

- Effective for drying water-based inks.

- Can be customized to different wavelengths for specific drying needs.

Cons:

- Higher energy consumption compared to UV and LED systems.

- Slower than UV curing for some substrates.

How to Choose the Right Lamp System for Your Flexographic Press

Selecting the best lamp system involves evaluating key factors, such as:

- Ink Type: UV inks require UV or LED curing systems, while water-based inks may need IR lamps.

- Substrate Material: Delicate substrates like thin films benefit from low-heat LED systems, while porous materials work well with IR.

- Production Speed: High-speed operations demand instant-curing UV or LED systems to keep up with throughput.

- Energy Efficiency: Choose systems with lower energy consumption to reduce long-term costs.

Benefits of Advanced Lamp Systems in Flexography

Consistent Results

Advanced lamp systems ensure uniform curing or drying, eliminating common defects like smudging or incomplete curing.

Enhanced Durability

Properly cured inks and coatings improve the longevity of printed materials, resisting scratches, fading, and environmental factors.

Increased Productivity

Faster drying and curing enable higher press speeds, boosting overall efficiency.

Environmental Benefits

Modern lamp systems, such as LED, are designed with sustainability in mind, offering reduced energy consumption and lower carbon emissions.

Maintaining Your Lamp Systems

To get the most out of your lamp systems, regular maintenance is essential. Here are some tips:

- Clean Bulbs and Reflectors: Dust and ink residues can reduce efficiency.

- Monitor Output: UV and LED lamps lose intensity over time. Replace them as needed to maintain curing quality.

- Inspect Cooling Systems: Proper ventilation prevents overheating and extends the lifespan of your lamps.

- Calibrate Regularly: Ensure the lamp system’s settings match the specific requirements of your inks and substrates.

Advancements in Lamp Technology for Flexographic Printing

IoT-Enabled Lamp Systems

Modern lamp systems are increasingly integrated with IoT technology, allowing for real-time monitoring, remote control, and predictive maintenance.

Hybrid Curing Systems

Hybrid systems combine UV and LED technologies, offering the benefits of both and increasing versatility for printers working with diverse substrates and ink types.

Energy-Saving Designs

Advancements in energy-efficient lamps, such as LED systems, are helping printers reduce costs and meet sustainability goals.

FAQs

What is the difference between UV and LED lamp systems?

UV lamps use traditional ultraviolet light and generate more heat, while LED lamps use diodes to produce UV light with minimal heat output and longer lifespans.

Can I upgrade my existing UV system to LED?

Yes, many manufacturers offer retrofitting solutions to convert UV curing systems to LED for improved efficiency and lower energy consumption.

What are the best lamp systems for water-based inks?

Infrared (IR) lamps are ideal for drying water-based inks, as they provide effective heat-based drying.

How often should I replace UV lamps?

UV lamps typically last between 1,000 to 2,000 hours, depending on usage and maintenance. Monitor their output to determine when replacement is necessary.

Are LED lamps compatible with all flexographic inks?

Not all inks are LED-compatible. Ensure your ink formulations are designed for LED curing systems.

What is the role of reflectors in lamp systems?

Reflectors enhance the efficiency of lamp systems by directing light onto the substrate, ensuring even curing or drying.

Conclusion

Lamp systems are the backbone of efficient and high-quality flexographic printing. From UV curing to LED innovation, these systems ensure consistent drying, vibrant prints, and sustainable production. By choosing the right lamp system and maintaining it properly, you can optimize your press’s performance while reducing energy costs and environmental impact.

As technology evolves, investing in advanced lamp systems will not only future-proof your operations but also elevate your printing capabilities to new heights.