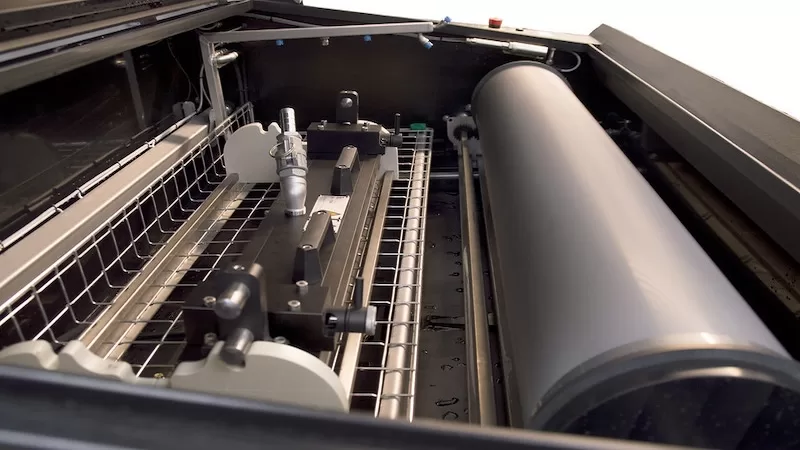

In the pre press process, after a design has been trapped, distorted to compensate for plate elongation, and electronically imposed (considering step-and-repeat requirements), the file is processed by the raster image processor (RIP) and output to film or plate. The RIP converts PostScriptTM data into a series of bitmapped images. The laser output device records this visual information received from the RIP onto film or plate material. Larger, more complex files will take longer to process through the RIP than simple text files.

Flexographic Image-Setting Requirements

© AGFA

© AGFAAccuracy

To optimise registration, output devices should meet a minimum standard of 1 mil over multiple separations. Geometric and absolute accuracy capabilities are also important imagesetters considerations.

Size

The imagesetter format size should be large enough to make the most effective and economic use of film, given the particular application.

© AGFA

© AGFA © AGFA

© AGFAFilm

All film for soft photopolymer plates should be output to matte emulsion film (thickness: 0.004″ as minimum; 0.007″ as preferred). This helps avoid trapping air between the film and plate during exposure.

Calibration

Film dot percentages below 10% should not vary by more than 1%; areas over 10% should not vary by more than 3%.

© AGFA

© AGFA © AGFA

© AGFAUniformity

Screen tints should be a uniform dot percentage, with no variation in size between individual dots.

Dot Shape

The imagesetter should be capable of outputting a “hard” round dot.

© AGFA

© AGFA © AGFA

© AGFAResolution

Resolution should be between 1200 and 4000 dpi. For line art, solids and type, 1200 dpi is adequate; halftones require a minimum of 2400 dpi.

Density

Film density is an important factor; imagesetter exposure levels and film processing chemistry should provide DMax areas of 3.5-4.0.

© AGFA

© AGFAThe Prepress Process

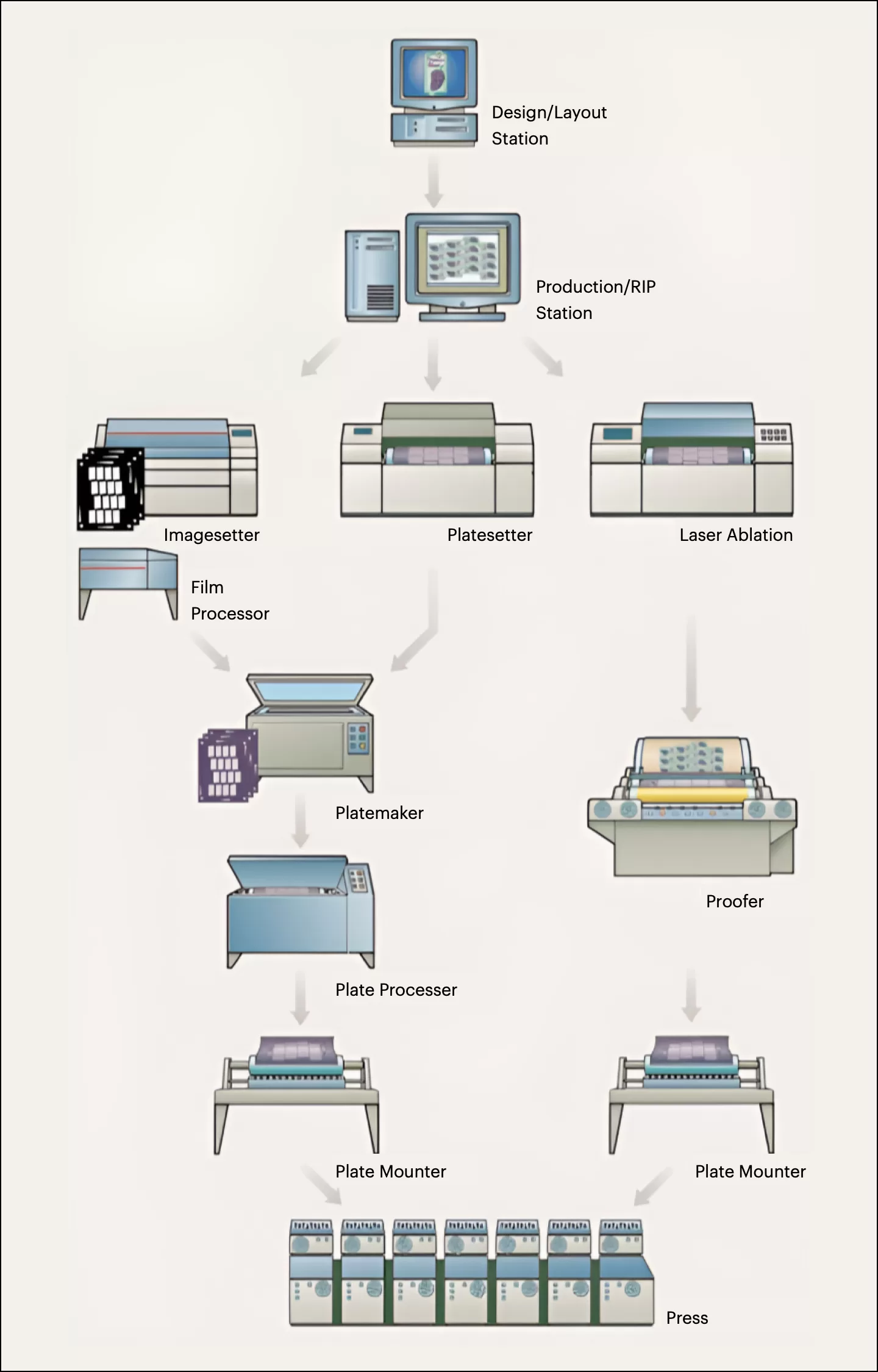

Following design, production and ripping, a job may take different paths through the prepress output and platemaking stages. For conventional photopolymer or rubber plates, jobs are first processed through an imagesetter, creating film output, which is used for plate exposure and processing. Plates are then placed on a mounting machine where, in some cases, a plate proof is made. A platesetter device essentially follows the same flow with the exception that the film processing step is eliminated. With direct-to-plate (or cylinder), devices, shown below as laser ablation, both platemaking and processing steps are eliminated.

© AGFA

© AGFA