This article is part of the FLEXO FLAW FIXING series

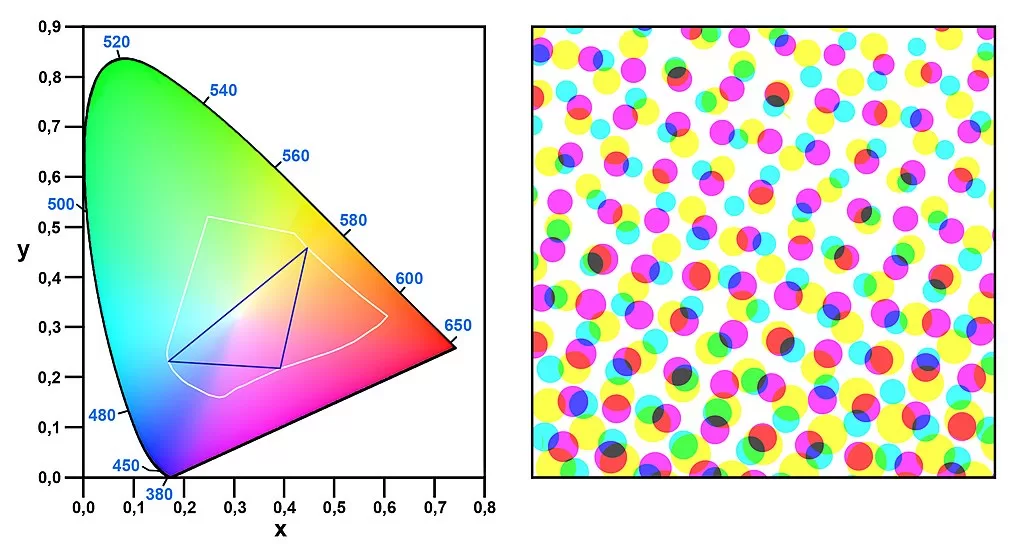

Colour is critical in flexo printing. It defines the final product’s quality and appeal in the specialised field of flexo printing. When colour strength falls below the expected threshold thus being too low in flexo printing, various issues arise. As a result, printed materials may lack the vibrancy needed to stand out in a competitive marketplace.

Diagnose of Low Colour Strength

While diagnosing this issue may seem daunting, there are reliable methods for identification. Print an adequate length of material and compare it with a reference from a high-strength press setup to observe differences in vibrancy. A lower colour strength print often appears faded in comparison, flagging potential problems within the press operation.

It’s important to detect and diagnose low colour strength early. This ensures that output meets the high expectations of customers. Addressing issues related to weak colour strength is therefore not an option, but a critical requirement of the flexo printing process.

Remedies of Low Colour Strength

Colour of Ink Being Too Weak

- Remedy: Contact the ink supplier for advice or improve colour strength by incorporating a concentrated ink.

- Checkpoints: Operators should continuously calibrate press settings, as well as use ink formulations tested for colour stability.

Ink Being Too Thin

- Remedy: To improve colour output, increase ink viscosity by adding fresh ink to the mixture.

- Checkpoints: Perform viscosity checks methodically throughout the printing process to maintain ink consistency.

Incorrect Ink Quality

- Remedy: Quickly transition to using the correct ink quality and specification to resolve colour strength dilemmas.

- Checkpoints: Initiate thorough quality checks on all inks before use and insist on using inks that meet the supplier’s specifications.

Ink Drying on Anilox Rollers

- Remedy: Regular and thorough cleaning of anilox rollers to prevent ink from drying and clogging the cells.

- Checkpoints: Consistently monitor and replenish ink levels as needed; implement a cleaning schedule to keep rollers free of debris

Low Cell Volume Anilox Rollers

- Remedy: Select anilox rollers with a higher cell volume that will carry and transfer more ink to the plate, resulting in a richer colour application on the substrate.

- Checkpoints: Regularly check the anilox inventory for condition and volume suitability as part of routine maintenance; replace or regroove rollers that do not meet the desired specs to achieve the correct volume transfer.

Anilox Roller Wear

- Remedy: Timely replacement of worn anilox rollers is essential to maintain ink transfer efficiency and colour strength.

- Checkpoints: Establish a program of regular roll evaluation and maintenance to extend roll life and performance.

Improper Printing Pressure

- Remedy: Critical print pressure adjustments between the plate cylinder, substrate, and anilox roller can correct problems caused by incorrect pressure settings.

- Checkpoints: Regular calibration and pressure setting evaluations should be standard practice to prevent future pressure imbalances.

Conclusion

In summary, the foundation of vibrant and consistent colour in flexo printing lies in proactive management. Addressing potential variables that impact ink and colour is vital. From precise cleaning of anilox rollers to vigilant monitoring of print pressure, each preventive measure plays a critical role in mitigating the risk of weak colour strength.

Implementing routine solutions and checks help achieve desired colour vibrancy. Thus, flexo printers can consistently deliver high-quality prints. The value of prevention cannot be overstated; it is the linchpin of quality assurance in flexo printing.

![[Flexo Flaw Fixing] Inconsistent Repeat Length Repeat length in flexo printing](https://flexopedia.net/wp-content/uploads/2023/06/066_Repeat_Length-jpg-e1704202472468.webp)