In flexography printing, die cutting plays an important role. With die cutting, the print job is faster and requires less hands-on effort, which can be difficult with miter saws and other cutters. Because die cutting eliminates the need for precision cuts, it is an efficient and accurate printing method. Furthermore, die-cut paper can be handled and printed on more easily due to its slimmer thickness. Lets look at the advantages and disadvantages of rotary die cut machine in detail.

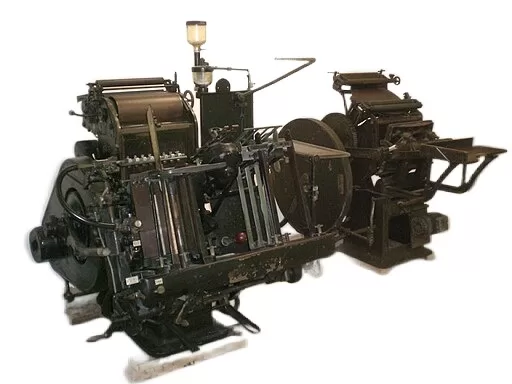

What is Rotary die cut?

Printing with rotary die cut involves cutting a die into a variety of shapes, such as circles, squares, and other patterns.

Compared to traditional printing methods, this allows the printer to produce intricate and detailed prints.

There are two types of rotary dies.

- Solid die

- Magnetic die

Advantages:

There are a variety of designs that can be printed using the rotary die cut, which is a simple, efficient, and affordable printing method.

The fact that rotary die cut printing produces more accurate cutting may make it a better choice for flexography printing.

As a result of die cuts, less offset is created, and the finish is more efficient.

Furthermore, die cuts can be customized to produce unique designs that are hard to replicate without special equipment.

Intricate designs and custom shapes can be created with rotary die cuts.

Rotary die cuts are ideal for those who want to create unique pieces since they are hard to replicate using other methods.

There are a variety of rotary die cutters available for small businesses and amateur printers.

Their affordability and ease of use make them an excellent choice for those who want the best results.

As rotary dies produce a precision product, they are a popular way to cut products.

Additionally, rotary die cuts offer many advantages over standard cutting techniques when it comes to response time and accuracy.

Disadvantages:

Although magnetic rotary die is less expensive than a solid rotary die, but the rotary die cut method has its own cost and is not feasible for small volumes.

It may be necessary to make specific settings in order to produce accurate prints with this product.

In particular, precision is a challenge when using the die cut feature.

Due to its die-cut feature, rotary die cuts may be less versatile than other printing options.

FAQs:

What is the difference between Rotary die cut and flexography?

Rotary die cut machines are used to cut intricate designs, while flexography is a printing process where images are reproduced using flexographic plates.

Conclusion:

Rotary die cut in Flexography is a process where high-quality images are cut out of flexible materials, such as vinyl and paper.

This method can be used to create intricate designs and patterns that would be difficult or impossible with other types of graphics production methods.

You can buy Anvil Covers and Cutting Blankets at Anyflexo Marketplace