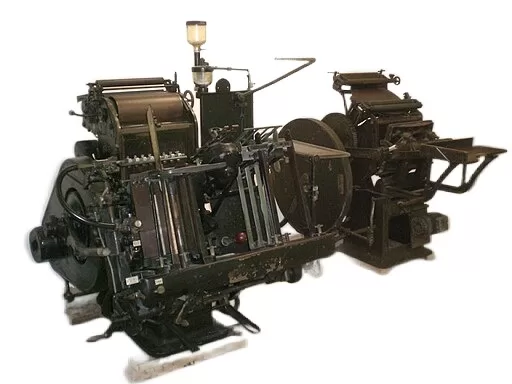

Flexo printing continues to be a cornerstone in the packaging and label printing industry. Within this sector, the stack-type flexo printing press stands out as a resilient and flexible player. This powerhouse of printing is lauded for its robust design, with each print station stacked vertically, making it a recognisable staple in many print workshops. The importance of stack-type flexo presses is undisputed; they are particularly favoured for their ability to handle diverse substrates and deliver quality prints at affordable costs.

Advantages of Stack-Type Flexo Press

The stack-type press offers a plethora of benefits, beginning with its versatile substrate compatibility – it can print on everything from fine paper to heavy cardboard. Additionally, each colour station operates independently, allowing simultaneous front and backside printing. Their open design facilitates easy access for rapid setup and cleaning, significantly reducing downtime between jobs. Moreover, the fixed architecture leads to a more stable printing process, resulting in high-quality outcomes for jobs where colour matching and print fidelity are paramount.

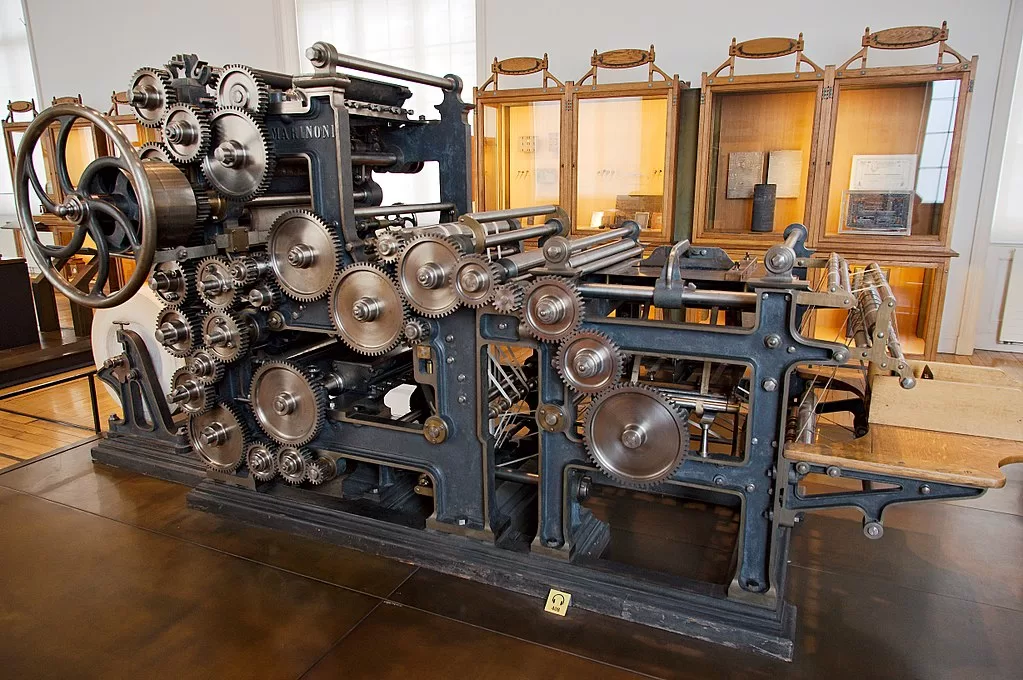

Mechanics and Operation of Stack-Type Flexo Press

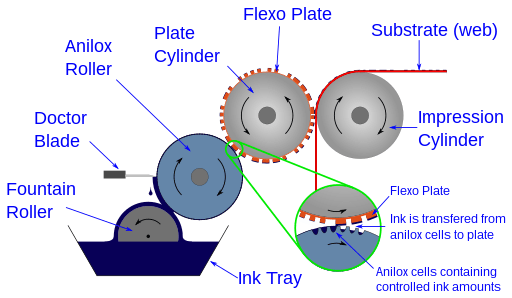

Anatomy of these presses is complex yet in methodical structure. They comprise key components such as anilox rollers, plate cylinders, impressing drums and drying units, each playing a crucial role in the print process. In terms of operation, stack presses maintain exceptional registration accuracy, thanks to the vertical arrangement of printing units. This layout permits a printing sequence that can be tailored to the job’s specific ink coverage and drying requirements.

However, their benefits extend beyond the components; the stack press’s speed is tailored for high-volume runs. Their unique build offers the reliability needed for bulk orders while maintaining a consistent print standard. Like any complex machinery, a stack-type flexo press requires regular care to operate at peak performance. Routine maintenance and precise calibrations are vital for sustaining the exceptional print quality and prolonging the lifespan of the press. This involves cleaning the rollers, ensuring proper alignment of the plates and fine-tuning the pressure between rollers.

Considerations When Choosing a Stack-Type Flexo Press

When considering a stack-type press for your business, it is essential to perform a thorough cost analysis and evaluate the potential return on investment. These presses are generally suitable for companies with high-volume, less complex jobs. The financial consideration should account not only for the initial purchase price but also for the ongoing operational cost, maintenance, and the manpower required to run such equipment.

Each business has unique needs, and machine specifications should align with these requirements. The nature of the orders, the types of substrates used, and the desired print quality are all factors that dictate the most suitable press configuration.

Despite their versatility, stack presses are not the perfect solution for every scenario. They are typically not favourable for extremely short-run jobs due to their setup time. Furthermore, for work requiring complex multi-process embellishments or ultra-high precision, other models such as in-line or central impression presses may be more suitable.

Conclusion

In the dynamic world of flexographic printing, stack-type presses have cemented their role as a reliable and efficient option. The pressing question for print shop owners is not if but how a stack press can best serve their operations. Its balance of cost-effectiveness, versatility, and quality makes it a valuable asset, particularly for those with consistent high-volume requirements.

Embracing a stack-type flexo press may very well be a stacking up of quality, performance, and profitability for the discerning printer looking to leave a bold imprint in the print market.