Varnishing in flexo printing refers to the application of a clear coating over printed materials to protect and enhance the final product. The purpose of varnishing is to provide a protective shield against environmental elements such as moisture, UV radiation and physical abrasion.

Unlike conventional varnishes used on furniture or works of art, varnishes used in flexo printing must complement the printing process and the substrates used to ensure that the final printed product is both durable and visually appealing.

Importance and benefits of coating

Protection from Environmental Elements

One of the main benefits of coating is the protection it provides against environmental factors. It acts as a barrier to moisture, which can be particularly important for printed materials that need to maintain their integrity in wet or humid conditions. In addition, coating protects against UV radiation, preventing printed colours from fading over time when exposed to sunlight.

Retaining Vibrant Colours

Coating plays a vital role in maintaining the vibrancy of printed colours. Coating enhances colour depth and gloss, making printed images stand out. This is particularly important for marketing materials where visual appeal can have a significant impact on effectiveness.

Prevention of Ink Turbulence

Ink turbulence, such as smudging or smearing, is a common problem that can occur during the handling and transportation of printed materials. A coating helps to prevent these problems and ensures that the print looks crisp and clean. Varnishing can also add a level of sophistication to the print, enhancing its overall appearance.

Maintaining Quality Over Time

Over time, printed materials can deteriorate due to wear and tear. Varnishing seals the print, helping to maintain its quality and extend its life. This is particularly valuable for items that are handled frequently, such as packaging, labels and brochures.

Key Considerations for Effective Varnishing

Safety and effectiveness must go hand in hand. Paints should be non-toxic and safe for users and end consumers. At the same time, they must effectively protect and enhance the printed materials. Achieving this balance is the key to successful coating.

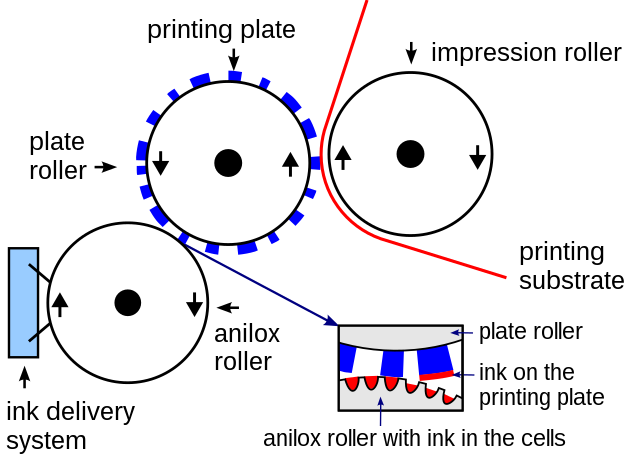

Proper Application and Gloss Control

Achieving the desired finish requires proper application techniques. The thickness of the coating and the method of application (e.g. roller or screen) must be carefully chosen to match the characteristics of the substrate. It is also essential to match the gloss level, whether gloss, matte or satin, to the aesthetic and functional requirements.

Ensuring Purity and Consistency

The purity and consistency of the coating affects its performance. Impurities can lead to defects such as blistering or uneven coating. Selecting high quality coatings and ensuring their consistency from batch to batch is therefore critical to achieving optimum results.

Avoiding Harmful Substances

Environmental and health concerns are becoming increasingly important in the printing industry. It is essential to use coatings that are free of harmful substances such as volatile organic compounds (VOCs). This not only promotes a safer working environment, but also ensures compliance with environmental legislation.

Post Application Care: Cleaning, Polishing and Maintenance

After coating, proper cleaning, polishing and maintenance of printing equipment is essential to prevent clogging and ensure consistent quality in future print runs. Regular maintenance will help extend the life of both the equipment and the printed material, ensuring that the protective benefits of the coating are fully realised.

Conclusion

In summary, varnishing in flexo printing is an essential step that significantly enhances the durability and visual appeal of printed materials. It protects against environmental damage, maintains vibrant colours and ensures long-lasting print quality.

Mastering varnishing techniques not only improves the final product, but also opens up new possibilities for creative and high quality printing. For those wishing to explore varnishing further, numerous resources and suppliers offer a range of varnishing products to suit different needs.