Introduction

When it comes to flexographic printing, the characteristics of the ink are paramount for achieving high-quality prints and maximising the speed of the press. Among the various types of inks used, solvent-based inks dominate the field of flexographic printing. Within this context, two critical factors that significantly influence the quality of solvent-based flexo inks are viscosity and pH value. In this article, we will delve into the importance of maintaining optimal viscosity and pH levels to ensure the smooth operation and productivity of flexographic printing processes.

The Crucial Role of Viscosity and pH Value of Flexo Inks

Viscosity refers to the measurement of a fluid’s resistance to flow. In the case of ink, viscosity is of utmost importance as it determines the flow of ink during the printing process. Maintaining the appropriate ink flow rate impacts the runtime of the printing process and the overall print quality on the substrate. pH, on the other hand, is a measurement of the hydrogen ion concentration in a fluid, indicating whether it is acidic or basic.

Viscosity and pH are closely related and have an inverse relationship. An increase in the pH value of solvent-based ink leads to a decrease in viscosity. Conversely, a decrease in pH value results in an increase in ink viscosity. Thus, it is crucial to maintain these two factors within the optimal range to ensure the smooth operation of flexographic printing processes.

Optimising Ink Performance in Flexo Printing

How Viscosity of Inks Impact on Flexo Printing

Viscosity has significant implications for printing productivity in flexographic printing. It greatly influences the behaviour of the ink, particularly in terms of achieving uniform ink volume on the substrate and ensuring precise colour distribution. Consistency in viscosity plays a vital role in achieving desired print quality.

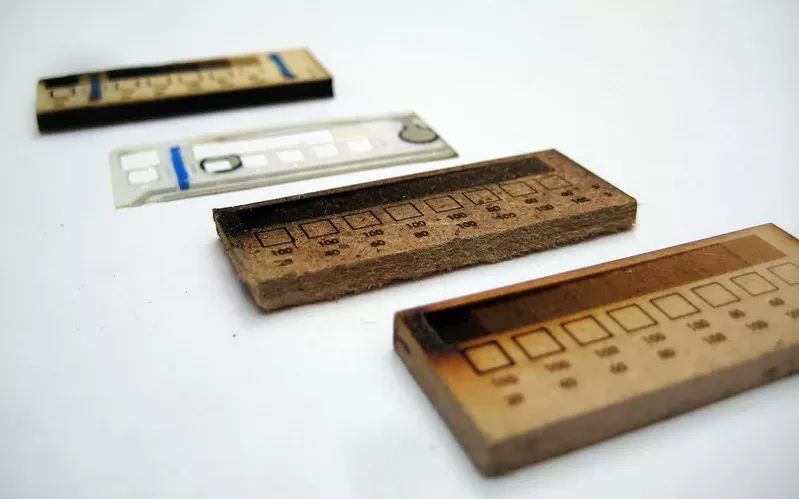

One key aspect affected by viscosity is ink consumption and printing cost. In water-based inks, ink solvents can be quite expensive. Even a slight variation of one second in viscosity, as measured by the #2 Zahn cup, can lead to a 50% increase in ink lay-down. Maintaining consistent viscosity levels is crucial for efficient colour management, minimising ink waste, and controlling printing costs.

High viscosity can result in extended downtime, as ink transfers slowly from the anilox rolls to the printing plate. This, in turn, can lead to ink clogging and cause printing jams or interruptions. On the other hand, low viscosity negatively affects print quality, causing colours to appear lighter and increasing drying time.

To ensure optimal printing productivity, viscosity should be carefully controlled. If viscosity is too low, adding more solvent to the ink is advisable. In contrast, if viscosity is too high, measures should be taken to reduce the viscosity. Ideally, the viscosity of the ink should remain consistent and not deviate beyond ±5%. Automated viscometers integrated into the printing machines can provide real-time viscosity readings and enable effective control. Additionally, maintaining viscosity within the desired range can result in significant ink solvent savings, up to 60%.

How pH Value of Inks Impact on Flexo Printing

Monitoring the pH value of ink is paramount, as it directly correlates with viscosity. As previously mentioned, pH and viscosity have an indirect relationship. Increasing the pH value of the ink decreases viscosity, leading to longer drying times and potential print quality issues.

Conversely, lower pH values increase ink viscosity, resulting in faster drying times and potential ink clogging during the printing process. Ink clogs can lead to printing jams, downtime, and reduced productivity. Thus, managing and balancing pH levels alongside viscosity is crucial for achieving optimal printing productivity.

By meticulously monitoring and adjusting pH values as required, one can effectively regulate ink behaviour without significantly impacting viscosity. Adding water to the ink lowers the pH value, while adding an appropriate solvent can raise the pH value as needed.

Ideal Viscosity and pH Value of Flexo Inks for Flexo Printing

Ink plays a pivotal role in the flexographic printing process, and both viscosity and pH values directly influence its performance. To enhance productivity in flexographic printing processes, the viscosity of ink as measured by the #2 Zahn cup should ideally fall within the range of 19-24 seconds. Similarly, the pH value should be maintained between 8.2 and 9.4. By closely monitoring and managing these two factors within their respective optimal ranges, smooth printing processes can be achieved, minimising ink wastage and excessive downtime.

Conclusion

Viscosity and pH are critical factors that significantly impact the performance of ink in flexographic printing processes. By diligently managing these factors, print quality and press efficiency can be enhanced. Deviations from optimal viscosity or pH levels can lead to poor print quality, increased downtime, and greater printing costs. Maintaining viscosity within the 19-24 seconds range and pH values between 8.2 and 9.4.