What is flexographic printing and why is it so predestined for pulp and packaging?

Flexographic printing – the term itself already hints at it: Flexo printing is a (highly flexible) printing process based on the use of flexible printing plates. These flexible printing plates are mostly made of rubber or elastic photopolymer, which can be easily clamped onto large printing cylinders (printing rollers) and can thus be used in web printing or rotary printing. For this reason, flexographic printing is also referred to as the modern web-fed rotary process in letterpress printing.

What makes flexographic printing so successful?

Flexographic printing is so efficient and successful because, as a highly flexible printing process, it opens up many different possibilities, and this applies in particular to the many materials in the consumer goods, food and packaging industries that can be printed using flexographic printing. The range extends from sturdy cardboard to thin film, from yogurt cup lids to PET water bottles and milk cartons (Tetra Pak). As a result, flexographic printing has achieved a global market share of around 40% as a packaging printing process (source: Prof. Dr. Dreher, DEFTA Technology Center).

How does the flexographic printing principle work?

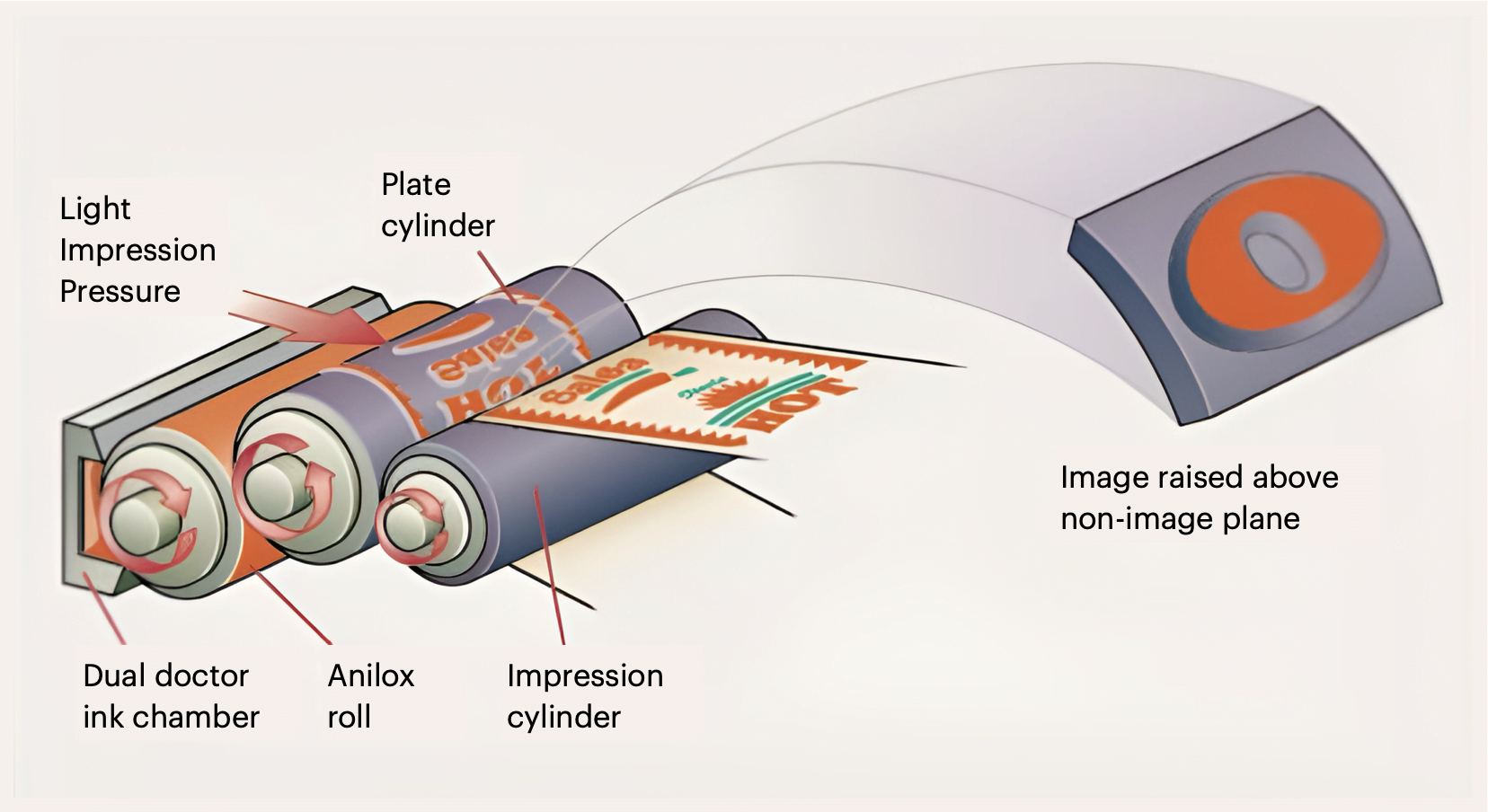

By definition, flexographic printing is a direct letterpress process. By “direct” is meant that the text or image motifs to be printed are transferred directly from the printing form to the substrate in flexographic printing. This means that the print motif must first be worked out mirror-inverted on a printing form. This is done, for example, by exposing light-sensitive carrier layers so that a relief-like motif is created on the printing plate. Only the remaining unexposed dots and areas of the motif remain as a raised, elevated surface/printing area and are used for ink pickup and transfer to the substrate or printing material.

What materials can flexo printing print?

Flexographic printing is a multigenerial, almost universally applicable printing process in terms of the range of materials that can be printed on. In everyday practice, flexographic printing is used whenever flexible materials need to be printed on rolls using rotary printing. These mainly include packaging materials made of paper and commercially available plastics. Flexographic printing is also frequently used for multi-component materials, elastic plastic films, banderoles and adhesive tapes. Flexographic printing is just as suitable for printing on somewhat thicker materials such as cardboard and paperboard or corrugated board.

Important substrates in flexographic printing

- Paper, cardboard, paperboard/corrugated board

- Insulation paper, crepe paper, glassine, pile paper

- Cellulose papers for bags, non-woven, wallpaper

- Labels, adhesive tapes, adhesive film

- Plastics (PE, PET, PVC, PS, PP etc.)

- Cellophane film, plastic film, aluminum foil

Overall, the range of applications for flexographic printing extends from packaging materials to forms preprints, carbonless copy sets and telephone directories to the production of thermal transfer papers for thermal transfer in the textile industry. Flexographic printing is very flexible.