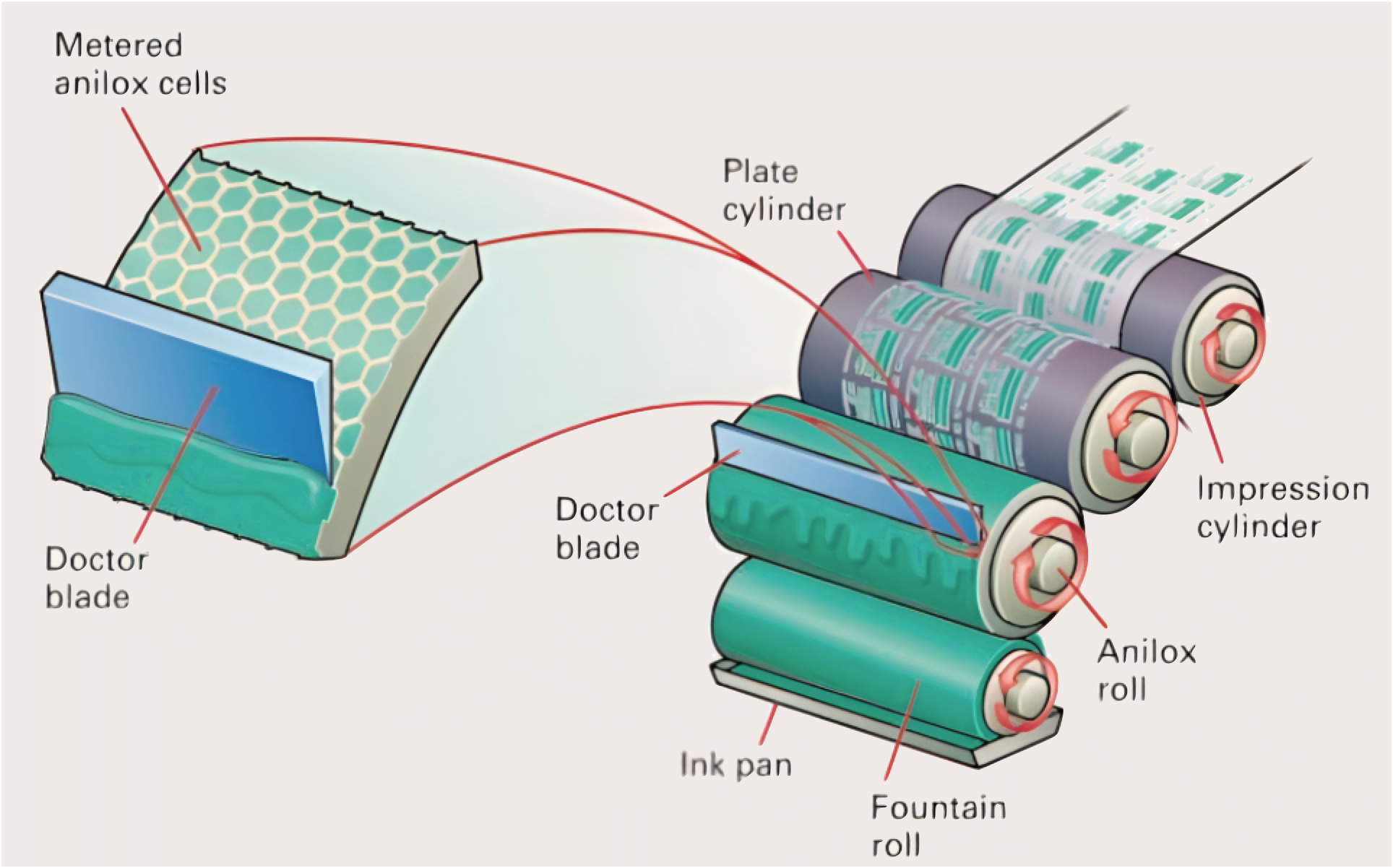

During Flexographic Printing, anilox volume refers to the carrying capacity of an anilox cell or the amount of ink held in each cell. It is one of many factors that influence the amount of ink transferred to the print material and must thus be precisely controlled and measured.

Anilox Volume 101: The Fundamentals

Understanding the significance of cell volume considerations in your flexo printing process begins with a thorough understanding of how the anilox works. The anilox measures and controls the volume of ink delivered to the image carrier.

The amount of ink transferred to the image carrier is determined by the size and number of engraved cells on the anilox, as well as the ink used. This cell volume determines both the amount of ink received by the image carrier and the density of the resulting ink.

Impact on Quality Printing

Remember that you are printing with a wet and fluid ink film, and it is advantageous to print with the thinnest ink film possible. As a result, you must ensure that your anilox volume, or cell carrying capacity, meets the specific printing requirements of your operation.

Thinner wet ink films are easier to control, reduce dot gain, and improve graphic capability. If you try to print in large quantities, you will have a difficult time achieving the best flexographic process in your facility.

Why is it important to have thinner ink films? Because there is less ink to transfer from the printing plate dot, dot gain decreases with thinner ink films. Thinner ink films effect:

- Dot Gain/Tonal Range

- Contrast/Fidelity

- Trap and Press Speed

- Ink Mileage

Thinner ink films yield:

- Predictable Dot Gain

- Clean Printing

- Smaller Dots

- Open Reverses

- Clean Type

- Sharp Edges

Anilox Volume Measurements

The carrying capacity of a cell is measured in billions of cubic microns (BCMs). Human hair is 70 microns thick in diameter, so microns are very small units of measurement.

The volume of a cell is measured in billion cubic microns per square inch, or BCM/in2. Microscopic measurement and liquid volume measurement are two common anilox cell measurement methods.

| Application | Anilox Volume Range |

| Heavy Line & Solids | 9.0 – 4.0 BCM |

| Line & Type | 8.0 – 1.0 BCM |

| Vignettes of Matched Color | 3.6 – 2.0 BCM |

| Vignettes of Process Color | 2.8 – 0.9 BCM |

| Process | 2.8 – 0.9 BCM |

Ink Considerations

According to the FTA, “it is critical to recognize that anilox volume is the single most important factor in determining ink film thickness.” For the best results in your specific type of operations, it is often beneficial to print with the thinnest ink film possible, and this must correlate with your anilox volume. High anilox volumes produce high solid ink density and more color, whereas low anilox volumes produce sharper graphics by transferring less ink to the image carrier.

It will be difficult to achieve optimal flexographic printing when printing with high anilox volumes. Wet ink thin films, on the other hand, make it simple to control the printing process. They allow you to achieve smaller dots, sharper edges, and, ultimately, cleaner printing by reducing dot gain.

Line Screen Considerations

The anilox volume and line screen interaction are two of the most important factors to consider when printing. To meet the needs of their specific printing job, a printer must be able to obtain the right combination of these two factors for their anilox roll.

A banded anilox is one tool that print operators can use to test and determine the proper set-up for providing adequate color strength while printing the thinnest ink film possible. Printing operators can now use higher line screen anilox rolls to produce higher line screen graphics thanks to modern manufacturing of high-strength inks and small carrying capacity cells (such as using an anilox volume of 1.0 BCMs for a 1,000 anilox line screen).

Overall, in addition to learning about anilox volume, it’s a good idea to understand line screens and anilox rolls.

Note: When determining line count on an anilox, a good rule of thumb is to make sure the line count is at least 6 times that of the line screen in your image carrier design. However, this is not a “one size fits all” rule, and you should always consult with your anilox provider to determine what is best for your print.

When Should You Replace Your Anilox?

Anilox cell volume changes over time due to factors such as dirt or anilox roll wear. It’s critical to measure the volume of your anilox regularly to check for wear and tear and ink plugging, which can degrade performance.

Poor print quality and other print defects could be caused by an anilox that simply needs to be cleaned or resurfaced. A thorough cleaning can restore colour and cell volume if the cells are dirty or blocked. However, if their wear is permanent, they must be resurfaced or replaced to avoid poor printing quality.