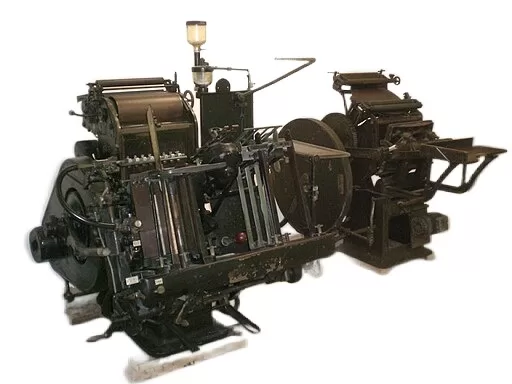

You’re probably aware of how flexo printing has evolved in response to economic and demand pressures. As industries produced more, they necessitated more packaging and stylistic options. As a result, flexo industry thinkers have gone back to the drawing board time and again to improve productivity and quality:

- More press uptime

- Higher speeds

- Continuous print

- Fewer printing defects

- Less time troubleshooting

- Less waste

- Brighter colors

- More diverse capabilities

Direct Laser Engraving Improves Flexo Printing Quality

Despite some lag time in North American flexographic market adoption, DLE has emerged in response to the prevalence of in-the-round (ITR) elastomer sleeves. ITR sleeves have evolved into the solution for a continuous, seamless print. Here are some of the advantages:

1. Increased Production Speed

When compared to conventional photopolymer plates, digital photopolymer plates, and simple laser-engraved plates, making an ITR elastomer sleeve press-ready requires far fewer steps. Because of their thickness and durability, elastomer sleeves can print continuously for 2-4 times longer than photopolymer plates. Furthermore, no additional labor or mounting materials are required. “Load-N-Lok” and you’re done.

2. Fewer Registration Issues

One of the most common flexographic printing flaws encountered in the industry is misregistration. Quite often, the issue is one of misalignment. However, it could also be caused by press mechanics or plate lift.

Plate lift does not occur with laser-engraved sleeves manufactured in the round. There will also be fewer issues with cylinder bounce and uniformity.

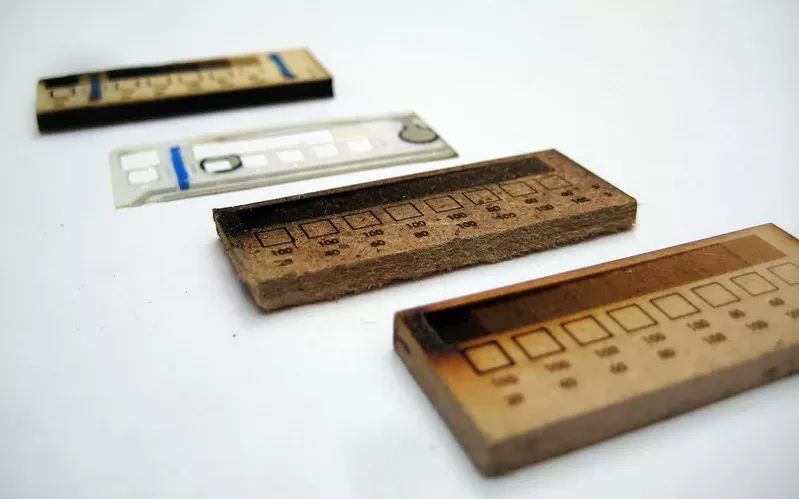

3. High Definition and Clarity

Laser engraving technology is capable of producing some of the most intricate and detailed images. Here are some examples of high-definition capabilities:

- Depths up to 0.125″

- Embossing 2D & 3D

- A basic non-serif font can have text point sizes as low as 0.75

- Gradient, vignette, and 4-color process screens with up to 175 lines

- Minimum line weight of 0.001″

- Multiple engraving profiles

4. Reduced Waste and Related Costs

DLE elastomer sleeves do not waste substrate because they do not have registration issues or are susceptible to wear and tear. This can also help to streamline your printing process and reduce labor costs. Your employees should be able to complete projects faster and move on to other tasks.

Quality and Efficiency Are Achieved With Direct Laser Engraving

Quality and efficiency are critical to the success of your flexo printing operation. You can now achieve high-end print results in a fraction of the time with direct laser-engraving technology and ITR elastomer. Your flexo sleeve investment could last a long time if you follow a good cleaning and maintenance routine.

Read next about Flexo Print Sleeves, Cylinders and Plates care and Maintenance