Flexographic plates play a crucial role in achieving top-notch prints for advertisements, packaging, and labels. To begin using a flexographic printer, the initial step involves preparing your artwork. One can achieve this by digitising the image or importing it into software capable of rendering the image as a file of proper flexo printing plate formats.

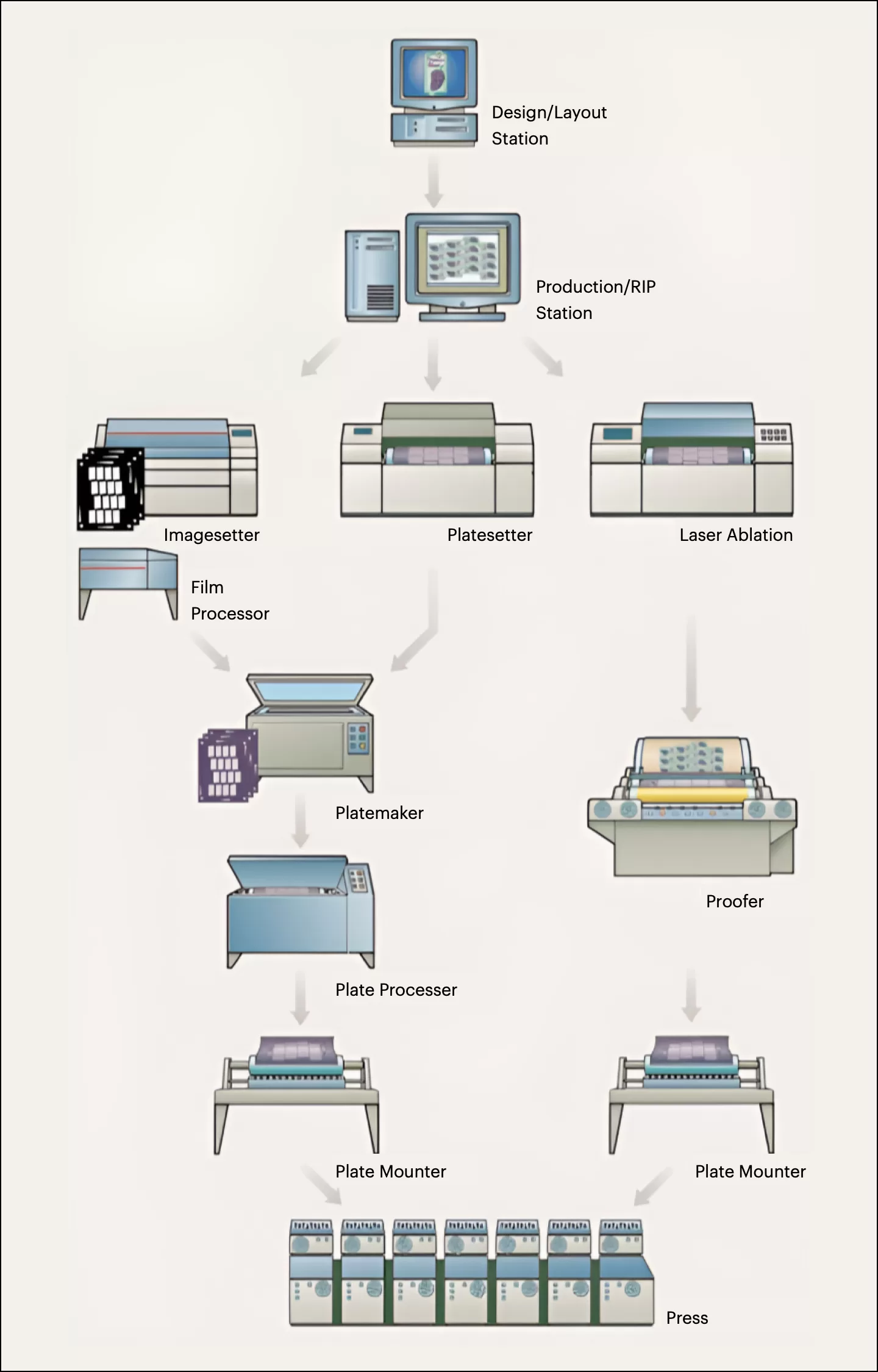

Subsequently, the next step entails obtaining the appropriate plates. These plates can be created using a flexographic printing plate maker or other conventional methods.

Once your artwork is prepared, it becomes necessary to load it onto the flexographic printing plate maker. This process involves heating up the machine and pressing the print head against the image.

Ultimately, the result is a print that possesses some degree of flexibility and can be easily manipulated. For the production of high-quality prints, a flexographic printing plate maker needs to meet specific criteria.

Which Flexo Printing Plate Formats Are Compatible with Plate Makers?

File formats are a critical consideration when it comes to flexo plates. To meet the requirements of printing firms and job specifications, one must be well-versed in the various formats needed.

Commonly, printers require PDF or PAF files for flexographic printing, along with potential needs for formats like CMYK or EPS, depending on the equipment utilised.

To ensure that your artwork is correctly formatted and handled, it is imperative to ascertain the specific file format your printer requires.

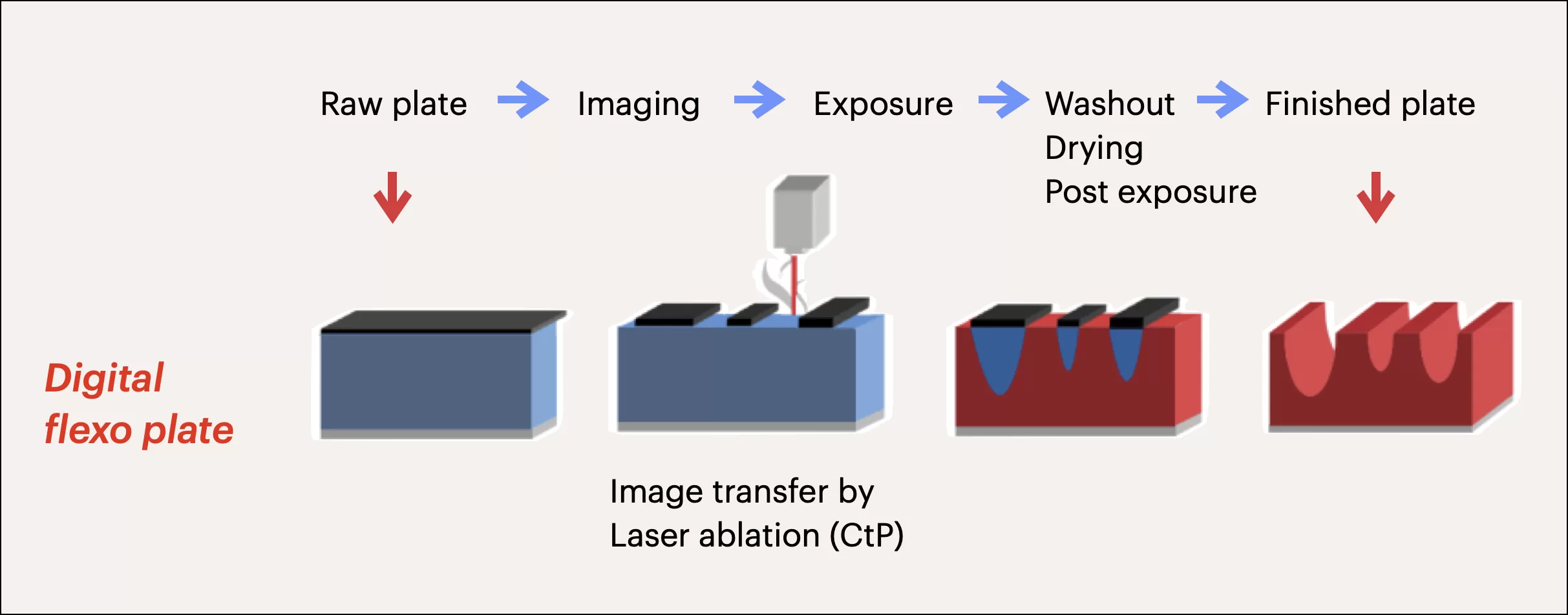

Transforming Images from the Initial Draft to the Final Plate

Moving from initial image drafts to the final plate involves careful consideration. Understanding plate types and requirements is key, as choices range from double-sided to single-sided printing plates. Ascertaining the specific needs for each print job is essential for producing high-quality results.

Defining these requirements might pose a challenge, but a comprehensive guide delves into multiple factors concerning image quality and file types.

To confirm whether your prints meet the required standards, it is advisable to reach out to either your plate maker or the printer’s manufacturer. They are best positioned to determine the requisite quality levels for specific printing tasks.

Key Formats of Draft Files

*.tiff (Tag Image File Format)

A widely used image file format in the printing and photo editing realms. Renowned for being lossless, it ensures no compression of the image file and facilitates the printing of highly detailed pictures.

*.pdf (Portable Document Format)

PDF is a versatile file format developed by Adobe for easy and reliable document presentation and exchange, irrespective of the viewing software, hardware, or operating systems in use. It is a prevalent file format for seamlessly sharing artwork from design systems to development systems, efficiently preserving all details.

*.ai (Adobe Illustrator)

A file format created by Adobe Illustrator, offering high scalability and compatibility with various Adobe programs. For detailed artwork requirements, Ai files are an unparalleled choice.

*.psd (PhotoShop Document)

PSD files are beneficial for image editing efforts, which enables extensive editing of image layers, with options available for conversion into other formats.

*.indd (INDesign Document)

If you utilise Adobe InDesign, the optimal choice is to craft artwork in Adobe InDesign and then transmit *.indd files to the plate exposing department to facilitate the preparation of flexographic plates.

*.jpeg (Joint Photographic Experts Group)

JPEG, a common picture compression format, utilises significant compression for compact files but may lead to distorted images when enlarged.

Prominent Features of Flexo Printing Plate Makers

Distinctive features set Flexographic printing plate makers apart. These features include the capability to adjust plate settings for various paper types, as well as the speed and precision exhibited during the printing process.

A standout feature of this printer is its capability to effortlessly generate custom plates of diverse sizes and shapes. This feature proves advantageous for businesses requiring bulk production of customised items such as signage or catalogues.

Furthermore, the bundled software with the Flexographic printing plate maker is user-friendly and easy to navigate, making it an appealing option for individuals lacking extensive computer programming experience.

Drawbacks of Flexo Printing Plate Makers

Despite the myriad advantages and benefits associated with Flexographic Printing Plate Makers, certain drawbacks warrant consideration.

Firstly, the computer software employed for plate creation can be relatively expensive.

Secondly, print quality may be inconsistent if updated software is not utilised or if different settings are not experimented with.

Thirdly, plate printing necessitates specialised materials and equipment that could be challenging to procure or costly to acquire.

Lastly, since Flexographic Printing Plate Makers generate graphically precise images that are intricate and accurate, errors can easily occur, resulting in subpar prints or even damage to the plate itself.

Frequently Asked Questions

- What Role Does LPI Play in a Flexographic Plate?

Linear pressure impressions are a crucial factor influencing the print quality of flexographic plates. Measured in pounds per square inch (LPI), it determines the print pressure required for a specific job. A higher LPI figure indicates a greater pressure requisite for producing satisfactory prints.

- How Can I Reverse Print in PDF?

If you intend to print a PDF document without the pages being reversed to display the front page clearly, follow these steps:

- Open the PDF document in the printing software on your computer.

- Locate the “Print” option in the program’s toolbar.

- Choose “PDF Output Options.”

- Within the “PDF Output Options” window, select the checkbox beside “Page Order.”

- Opt for “Reverse Print Pages” from the radio button options.

- Click “OK” to exit the window.