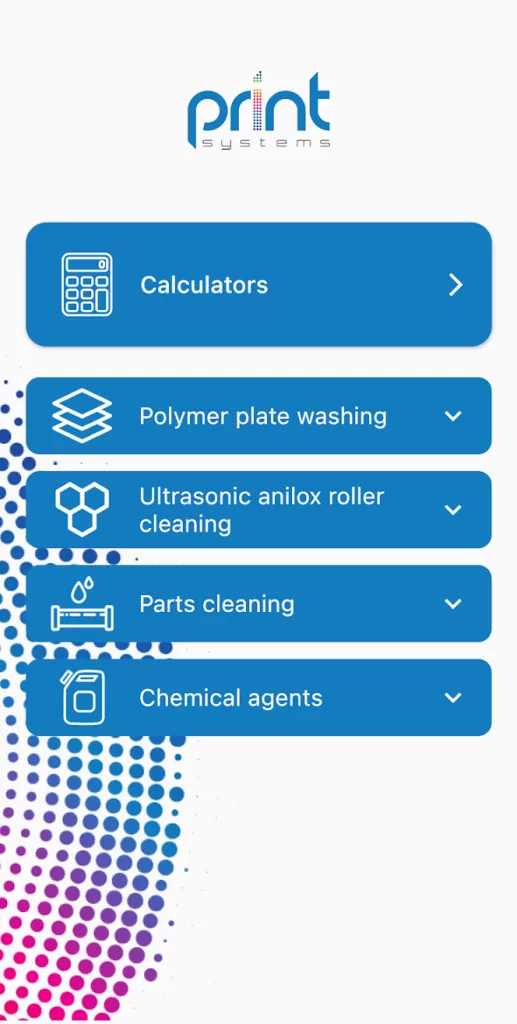

FlexoPrint is a special, useful and free mobile application. Excellent for prepress personnel responsible for photopolymer plate processing, print quality and consistency.

FlexoPrint mobile application includes professional flexo prepress calculators and configurators to facilitate routine work:

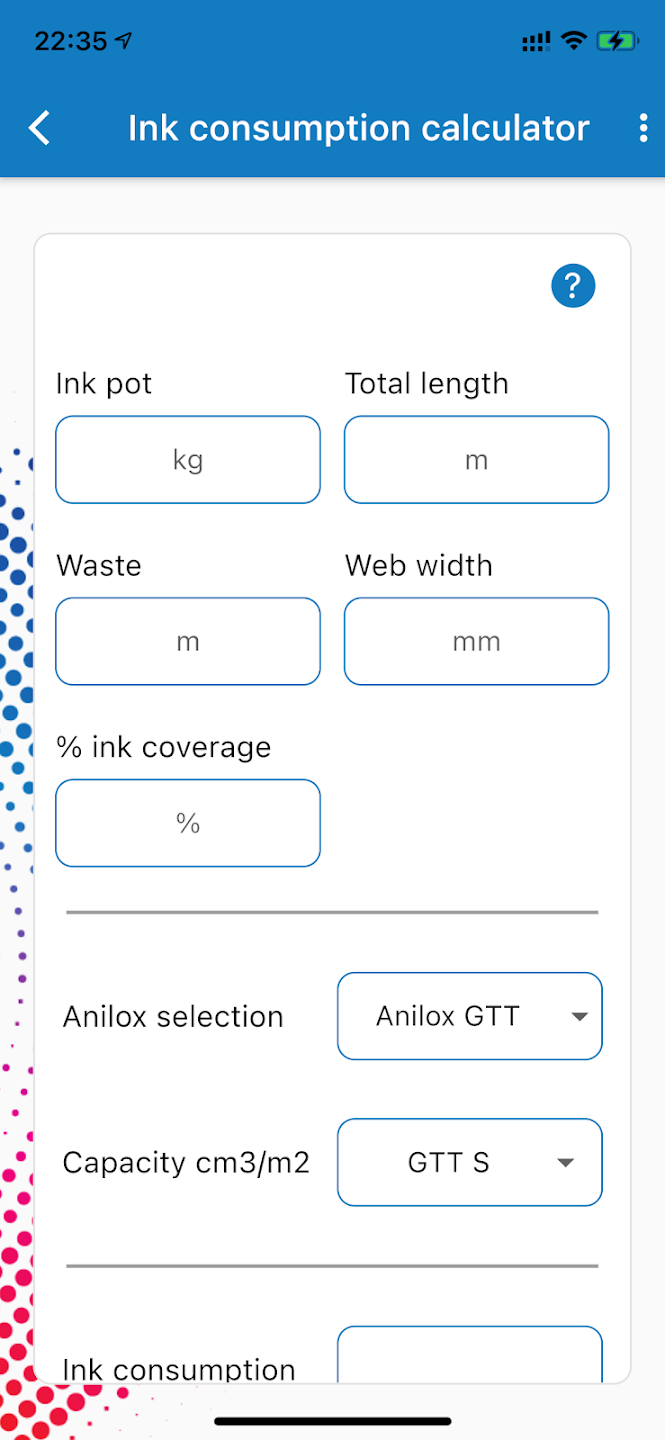

- Ink Consumption Calculator

- Roll Length Calculator

- Distortion Calculator

- Job Screen & Dot Diameter

- BCM-CM3-BCM Converter

FlexoPrint software supports both metric and imperial (inch) units.

You can find FlexoPrint mobile application in Google Play store for Android devices and App Store for iPhones.

© FlexoPrint

© FlexoPrintThe Ink Consumption Calculator

© FlexoPrint

© FlexoPrintThis calculator uses the parameters you enter, including the percentage of ink transfer, to determine the amount of ink you need. It does not take into account metering efficiency or the anilox situation.

All a small web needs is the above criteria. You don’t need to worry about things like repeat length, gear size, or pitch. Just fill in the blanks; don’t go to any more trouble than necessary!

For flood coating, fill in the Label Width section with the width of the tint roll. Label Length: Enter “12” here. The Quantity of Labels section prompts you to enter the roll length in feet. Type “100” in the Percent Ink Coverage field.

- Substrate Width

- Substrate Length

- Quantity of substrate, including any waste and overruns

- The minimum amount of ink required to operate a print station, including both the amount used and the minimum amount required to ensure smooth system performance

- Amount of anilox required for a given colour

- Percentage of ink transferred, taking into account both the amount of ink actually transferred from the image carrier to the substrate and the amount of ink that remains on the anilox roll after transfer to the image carrier

Figures are to be determined by experience and modified as necessary.

Based on the label area covered by the ink colour, or more specifically, the colour image area/label area, ink coverage percentage.

These figures, when added together, give the total amount of ink used in gallons for a job, as well as the amount of ink, also in gallons, that you will need to mix.

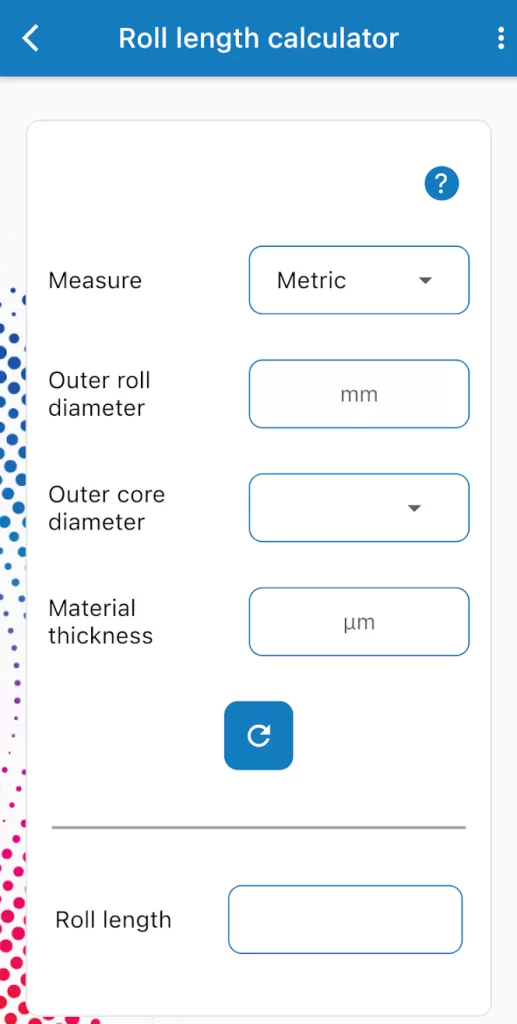

Roll Length Calculator

Given the outside diameter of the material, the thickness of the material, and the diameter of the hole in the centre or tube on which the material is wound, the rolled length of the material is calculated.

Variations due to stretching or softness of the material should be ignored. A rolled carpet or a rolled sheet of paper from a paper mill are examples of rolled materials.

The units of length that are available: inch, metre, centimetre, millimetre, mil, and micron. A mil is one thousandth of an inch. One micron is equal to one thousandth of a millimetre. The initial units of the table can be changed to any of the options provided.

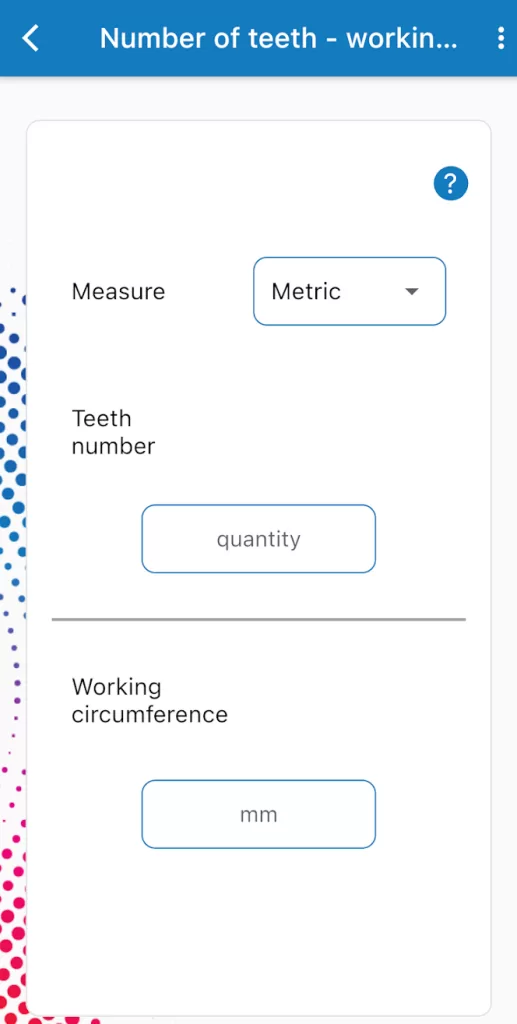

The print length calculation is based on the number of teeth of the print cylinder.

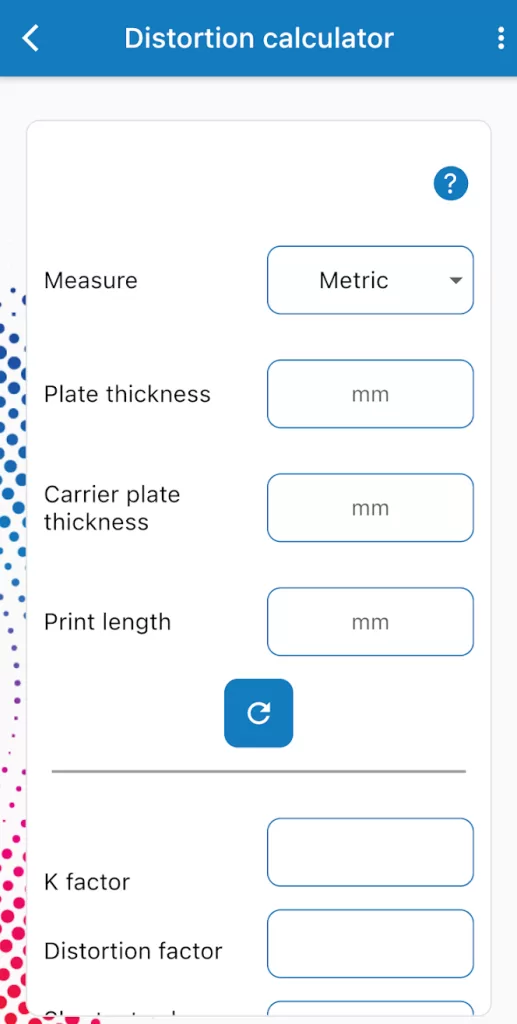

Distortion Calculator

Enter the thickness of the plate, the carrier plate (metal, foil, aluminium, etc.) and then the print length.

The K-factor is calculated. The calculated values give you information about distortion, such as the percentage of distortion.

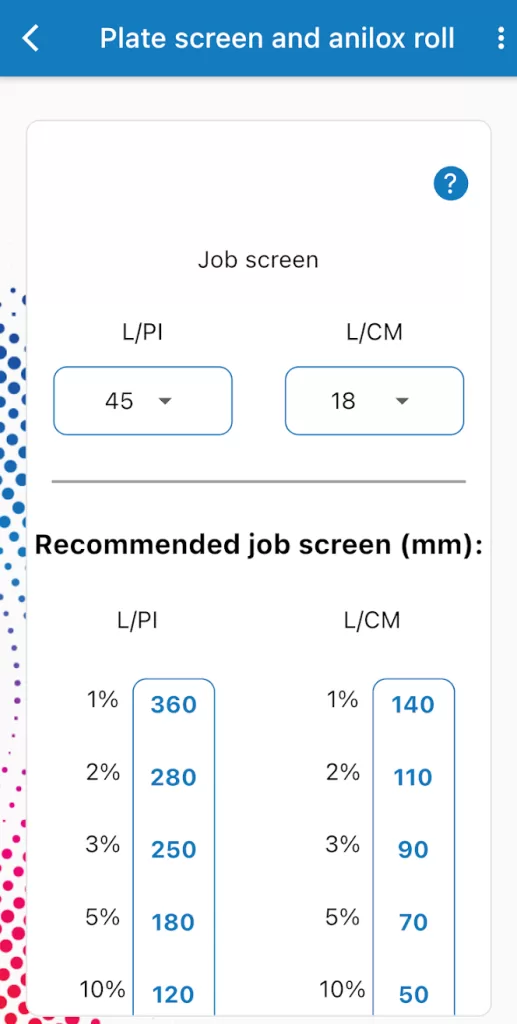

Job Screen & Dot Diameter

Plate Screen & Anilox Roll Screen

The calculator suggests the minimum anilox roll screen that should be sufficient to print each % dot value on the plate.

The calculator does not take into account many other factors that affect print quality.

Plate Screen & Dot Diameter

The calculator mathematically calculates the diameter in mm of the dots that should be produced on the negative film, CTP mask or plate for the given resolution and screen.

BCM ↹ CM3 Conversion

In any window, enter the units you want to convert.

The calculator converts BCM to CM3 and vice versa.