In today’s competitive market, smart packaging and effective branding have become essential tools for product success. Companies are increasingly turning to innovative designs to make their products stand out, and foil embossing has become a popular method for enhancing packaging aesthetics. From food and drink to luxury goods, foil embossing adds a touch of sophistication and uniqueness. Despite its advantages, the embossing process can encounter numerous challenges that require careful attention to ensure a flawless finish.

Common Challenges and Their Solutions

Insufficient Ink Drying

One common issue is insufficient ink drying before the foil stamping process. If the ink on the printed sheet hasn’t dried completely, the foil may smear when touched, and ink may transfer to the polyester film carrier or adjacent sheets on the feed table.

Solution: To avoid this problem, operators should test and verify that the ink is fully dried before proceeding with foil stamping. Implementing a structured drying time routine and using drying accelerants can also help secure properly dried ink, ensuring a clean, smear-free embossing result.

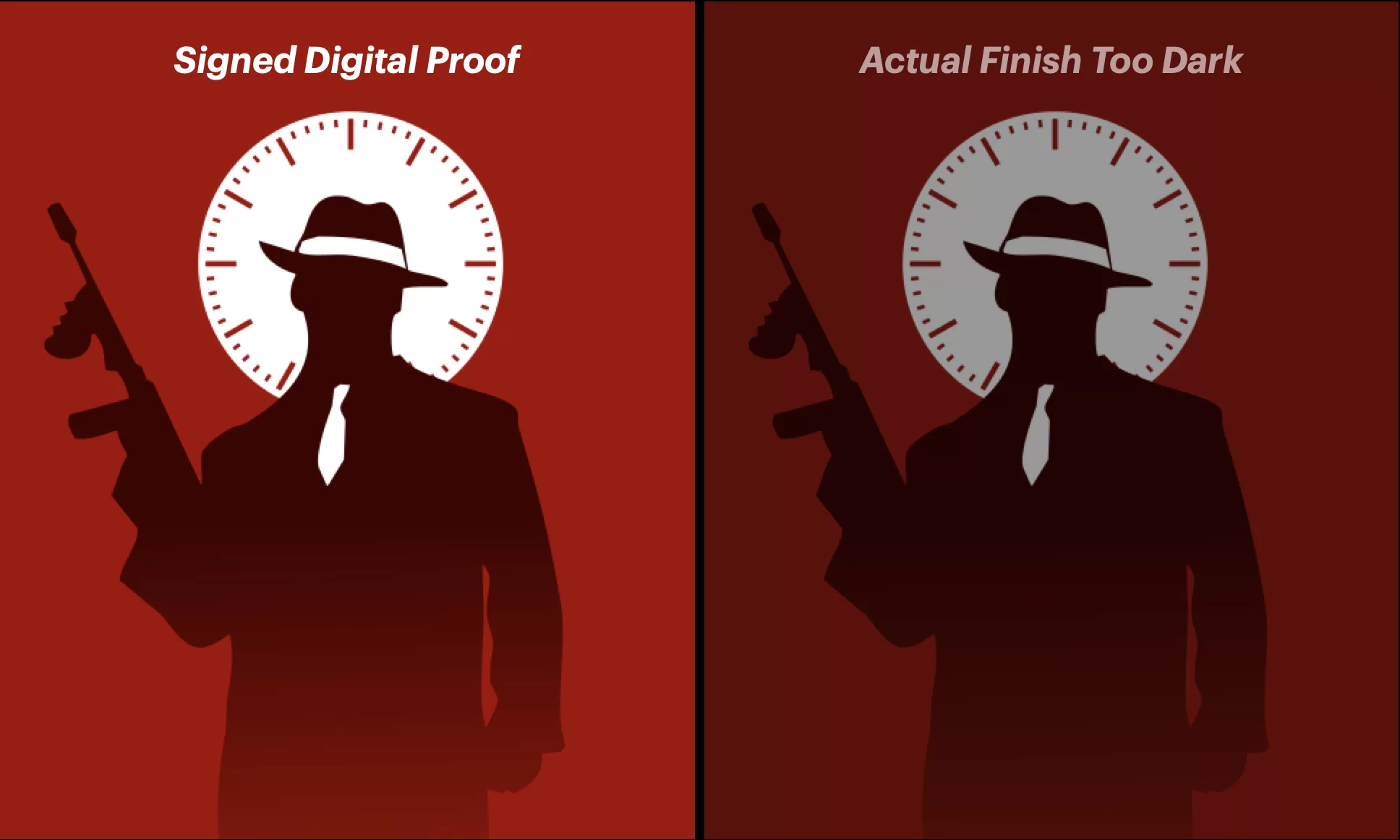

Design Flaw with Embossing Cylinder

The effectiveness of blind foil embossing hinges on the quality of the embossing cylinder. Poor design can lead to unclear or faint embossed details, especially for intricate logos or patterns.

Solution: Collaboration with an experienced image carrier service is vital. Conducting test embossing runs with preliminary cylinders allows identification and correction of design flaws. This practice catches imperfections early, saving significant time and resources before final cylinder production.

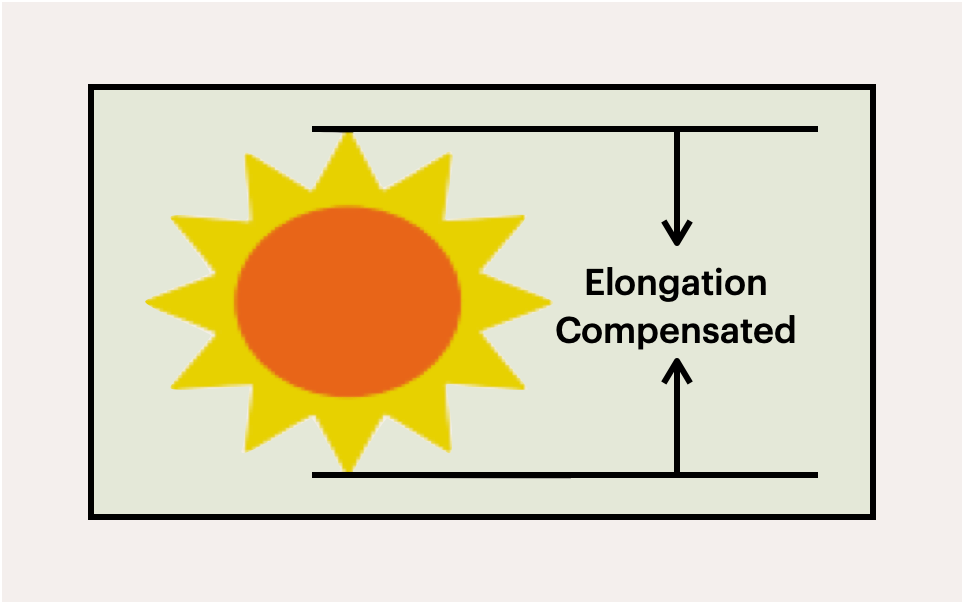

Inconsistent Pressure

Without consistent pressure, embossed elements can end up too shallow or overly deep, creating an uneven finish. This often happens when bearer bars are not included in the embossing plates or cylinders.

Solution: Incorporating bearer bars into the design stabilises the pressure across the embossing run. When working with your image carrier service, ensure bearer bars are implemented to minimise bounce and maintain uniform pressure, especially during high-speed operations.

Embossing Press Malfunction or Operator Error

Mishandling of embossing sleeves and improper press settings can lead to numerous defects, including alignment issues and unsatisfactory embossing results. Even minor bumps during transport or handling can disrupt the alignment and pressure settings.

Solution: Proper handling and meticulous press maintenance are crucial. Like a new car, treat embossing cylinders with utmost care, avoiding drops and impacts. Before starting a job, double-check press settings to ensure correct pressure and a clear substrate pathway, free from debris or foreign materials.

Expert Solutions for Flawless Embossing

Achieving a flawless foil embossing finish often requires expert assistance. Partnering with a reputable image carrier manufacturer can make a significant difference. These manufacturers provide comprehensive services, from testing designs and providing proofs to producing final cylinders. Their experience and precision ensure that the highest quality product is delivered, significantly reducing the risk of defects and rework.

Engaging with experienced professionals for your embossing needs guarantees consistency and superior results, bolstering your brand’s visual appeal and market presence. Regularly testing designs and maintaining open communication with your service provider will help catch potential issues early, ensuring smooth and successful embossing operations.

Conclusion

Addressing the common challenges of foil embossing is essential to achieving a high-quality, standout product. By understanding and solving issues related to ink drying, cylinder design, pressure consistency, and press operation, manufacturers can ensure a flawless embossed finish. Collaborating with skilled image carrier services further streamlines the process, offering long-term advantages and enhancing your product’s market appeal. Invest in the right solutions to overcome embossing obstacles and witness the transformative power of impeccable packaging.