The article was prepared and submitted to us by Troika Systems Ltd.

In the previous part, we discussed about the advantages of having an anilox roller inspection device and programme. This article is part 3 of the series on how to inspect anilox rollers.

Act before it Happens

Sonia Acros from Cheshire Anilox Technology mentions that “a preventive maintenance program is fundamental to ensuring maximum performance from anilox rolls. This means not only ensuring rolls are thoroughly cleaned after each use but also tracking their essential data points.“

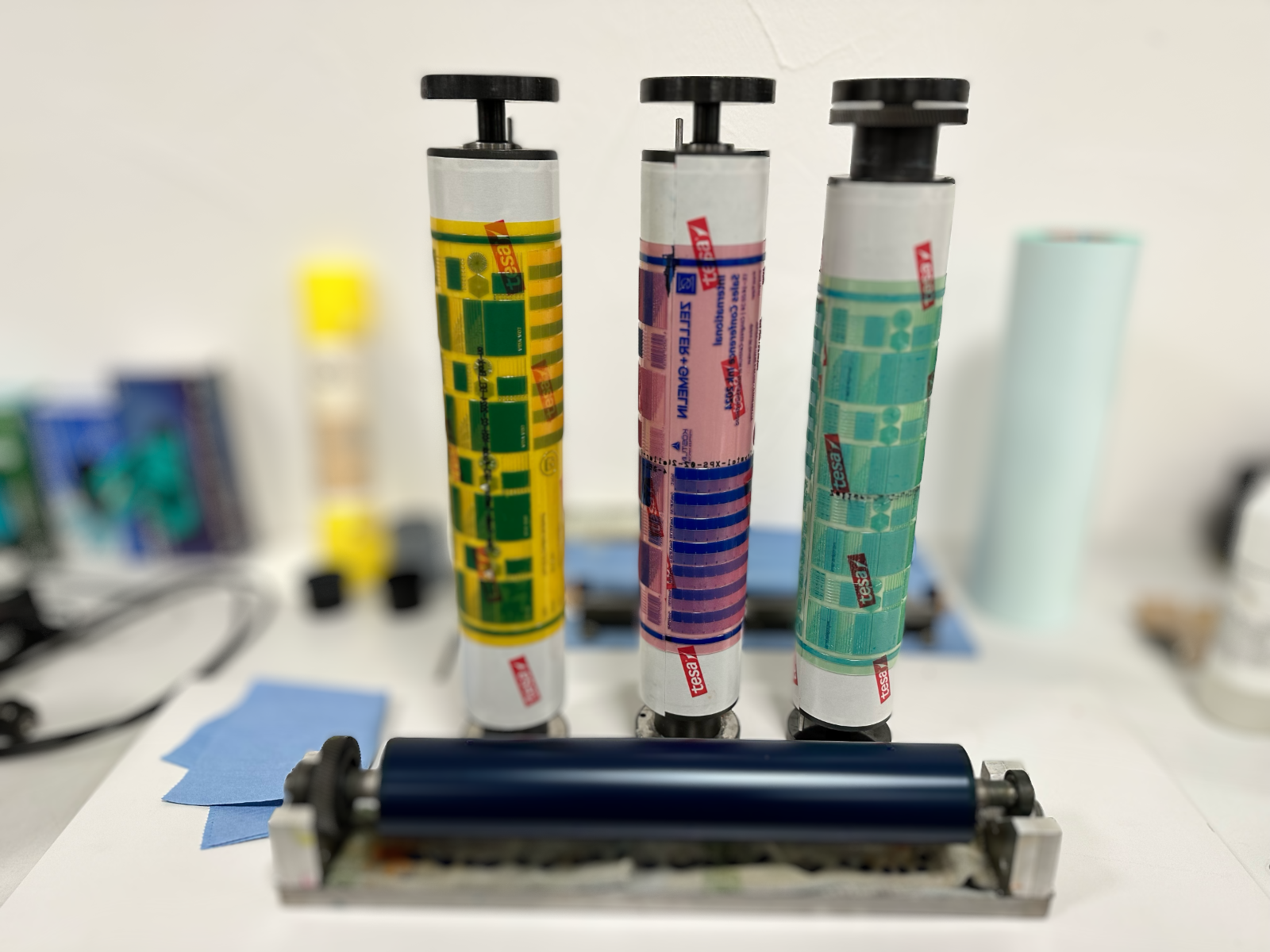

Doe their anilox rolls meet the criteria logged the last time that job was successfully produced? This is the thing converters need to be aware of prior to starting a new job. This process includes measuring the volume of the anilox roll. Equipment includes Capatch strips, ink drawdown tests, high-power microscopes, or interferometric cameras, etc.

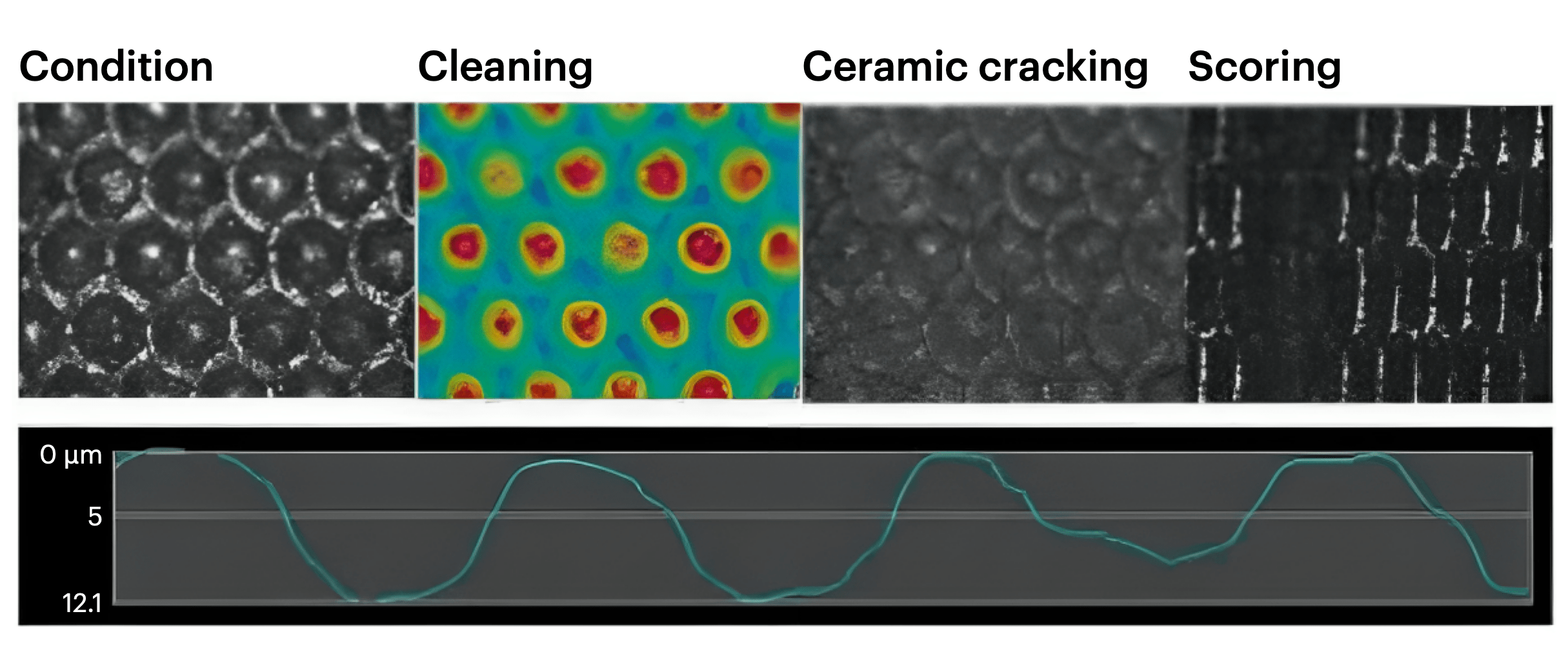

It is crucial that when an anilox roller goes back to storage, any chips or scoring lines are in documentation. One should measure the volume and capture the data. This helps the pre-press department understand that the roll is fully ready to run the next job.

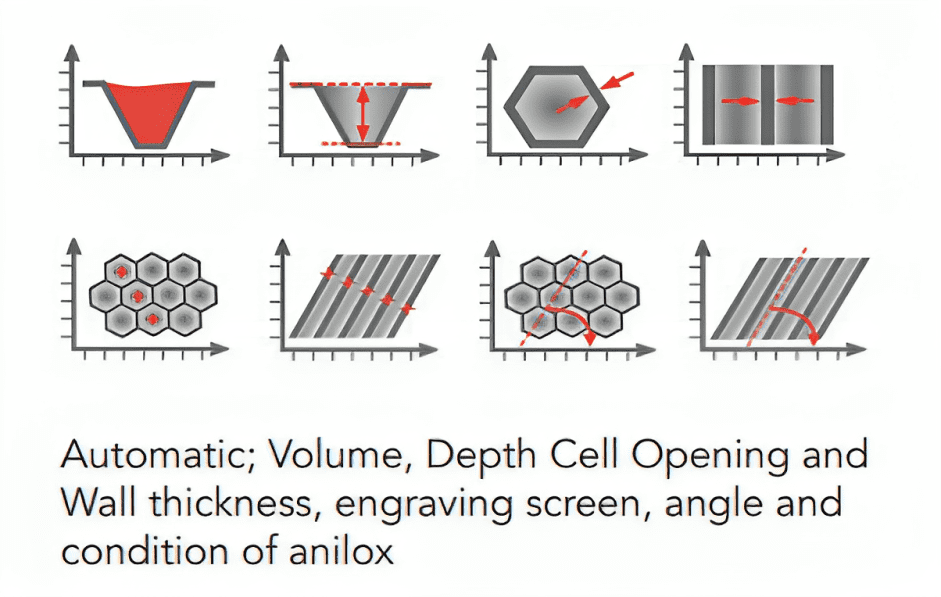

Ms. Acros continued, “Our engineers can conduct an anilox audit in a relatively short time with minimal press disruption. Using a high-powered digital microscope, they inspect the rollers for screening parameters, cleanliness, wear, damage, and any other aspects that affects their performance. However, since suppliers are not in a printer’s facility every day, printers should invest in measurement tools. They should gain knowledge to diagnose and address print issues themselves with the help of tools.”

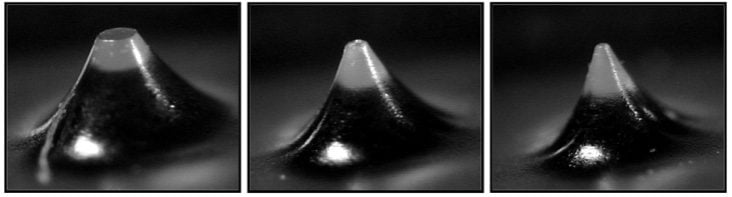

You need a well-lit area to inspect the engraved surface visually. The anilox roll is supported by precision bearing blocks during visual evaluation. After that, the next logical step is to inspect the engraved surface closely with the help of a magnifying device. You need to inspect the engraved surface closely enough to determine if it is plugged, worn, or damaged.

Factors to Heed

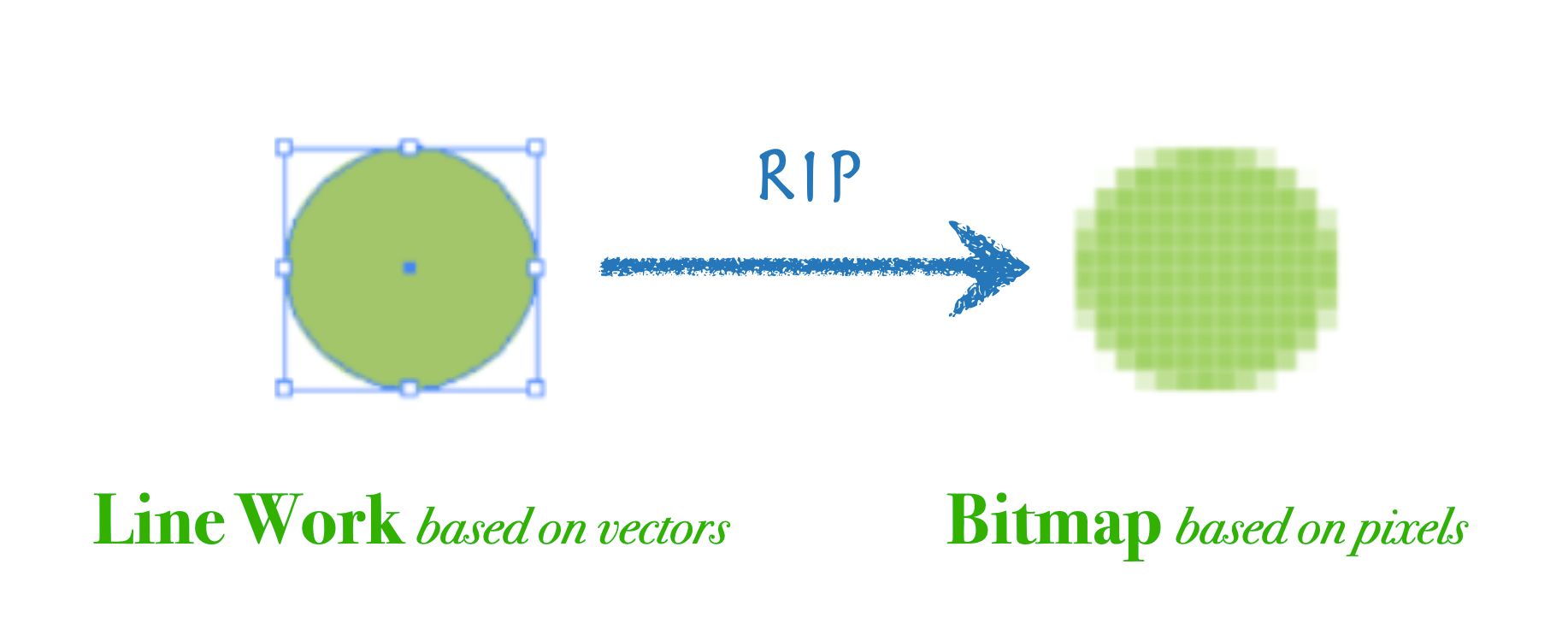

The primary controlling factor in flexographic printing is cell volume. To ensure print consistency, the printer’s process needs to be optimised through scientific testing. Also, the anilox rolls need to be standardised for each print application.

When optimised for various printing elements, including solid coverage, line work, screens, process work, and combinations, the anilox roller’s performance is standardised to reproduce line colours, solid ink density targets, and acceptable dot gain values.

Part of the inspection process should involve comparing the solid ink density and/or line color transferred by the new roll to established standards. This comparison of roll performance can be used throughout the life of the anilox roller by utilizing running targets on live jobs. Again, after each test is performed, this data should be logged properly by the pre-press department to avoid using substandard anilox rollers.

Ms. Acros concludes by saying, “Implementing a maintenance and inspection process will save the converter lots of money and time in anilox roll purchases, long setup times, water press issues, ink wastage, wasted stock, and lost business.”

This serves as part 3 of a three-part article series on how to inspect anilox rollers. Check parts 1 and 2 for more inspiration.