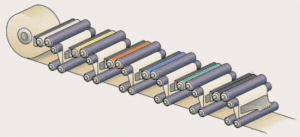

Flexo printing has long been synonymous with versatility and adaptability, suiting a range of applications from packaging to labels. At its core, the in-line flexo press is pivotal to this reverence, streamlining the printing process with an assembly line approach that enhances both productivity and precision.

Why In-line Flexo Press?

One of the most compelling advantages of in-line flexo presses is their unwavering efficiency. These machines are capable of performing multiple tasks – from printing to die-cutting, to laminating and scoring – in a single pass. This not only speeds up production times significantly but also ensures uniformity across the production run with consistent high-quality prints. For businesses, this translates to faster turnaround times and heightened customer satisfaction.

© AGFA

© AGFAMechanics and Operation

An in-line flexo press boasts an array of rollers, plates, anilox cylinders, and drying units that work in unison to deliver the final product. Although the process sounds complex, each component is there for easy operation. The central impression cylinder anchors the substrate, providing a stable base for intricate designs, while the rapid drying process ensures that the prints are touch-dry and ready for immediate finishing or packaging.

Routine challenges such as ink mottling, improper registration, and die-cutting issues can hamper productivity but can often restore with mitigation with proper maintenance and calibration. Newer presses have self-adjusting systems to correct these issues mid-run, thus reducing waste and downtime.

Considerations When Opting In-Line Flexo Press

The average cost of an in-line press ranges from $500,000 to $2 million, depending on the number of colours, width and options. The initial cost of a press shouldn’t be the only consideration.

The ideal press purchase should be tailored to each company’s needs. Choosing an in-line flexo press is a strategic decision on the basis of the specific needs of a business. Factors like the intended print run size, substrate material, and the intricacy of the images all play a crucial role in selecting the right press.

Even if the price is a little high, it’s worth considering the return on investment. Furthermore, certain presses offer modular designs, allowing customisation and upgrades to meet evolving business demands without replacing the entire system.

Technological Integration and Eco-Friendliness

The latest in-line flexo presses are a testament to technological innovation, integrating digital controls for enhanced precision and minimal manual intervention. Such advancements are also paving the way for greener printing solutions. Presses now boast features that minimise waste and promote the use of recyclable materials and water-based inks, reflecting the industry’s commitment to environmental sustainability.

Scenarios where In-line Flexo Press is Disadvantaged

While the text above showcases the advantages of in-line flexo presses in enhancing print efficiency, it’s important to note scenarios where an in-line press might not be the optimal choice in flexo printing:

- Limited Space

In-line presses typically require more space due to their assembly line approach and the inclusion of multiple components like drying units, anilox cylinders, and additional rollers. In smaller printing facilities with space constraints, a compact or modular press setup might be more suitable.

- Specialised Printing Needs

For extremely specialised or customised printing requirements that demand unique processes or additional embellishments beyond what an in-line press can offer in a single pass, a different configuration, like an offline finishing unit or specialised machinery, may be more appropriate.

- Low-Volume Jobs

In-line flexo presses are optimised for high-volume production runs where the efficiency gains justify the investment. For businesses that primarily handle low-volume or variable printing jobs, the cost-effectiveness of an in-line press setup might not align with their needs.

- High Variety of Substrates

If a printing operation frequently switches between a wide variety of substrates with specific requirements (such as thickness, texture, or material), the limitations of an in-line press in accommodating these diverse substrates efficiently might make a modular or offline setup more versatile.

By considering these factors, businesses can make informed decisions about whether an in-line flexo press aligns with their operational requirements or if alternative printing solutions might better suit their needs.

Conclusion

To conclude, in-line flexo presses represent a nexus of productivity and innovation in the printing industry. As they evolve, they bring smarter, more sustainable printing solutions to the fore, promising a future where quality, efficiency, and ecological responsibility go hand in hand.

In an industry driven by speed and accuracy, in-line flexo presses offer the best of both worlds – a boon for printers looking to stay competitive and for clients demanding precision and promptness. The onus is now on printers to harness these advancements, ensuring they remain at the cutting edge of print technology.