What Constitutes an Anilox Roller in Flexo?

An anilox roller, a critical component in flexographic printing, consists of a steel or aluminium core enveloped by industrial ceramic, often Chromium oxide powder. And since its surface is intricately etched with myriad dimples called anilox cells, it facilitates precise ink transfer to the substrate.

Functionality of Anilox Rollers

In the printing process, anilox rolls work in tandem with inking units to deliver ink onto paper. The ink is transferred from the anilox roll to the doctor blade plate, ultimately reaching the printing plates, which are specialised surfaces designed to receive and retain ink. Specifically, common plate materials include polyester film, photopolymers, and metals.

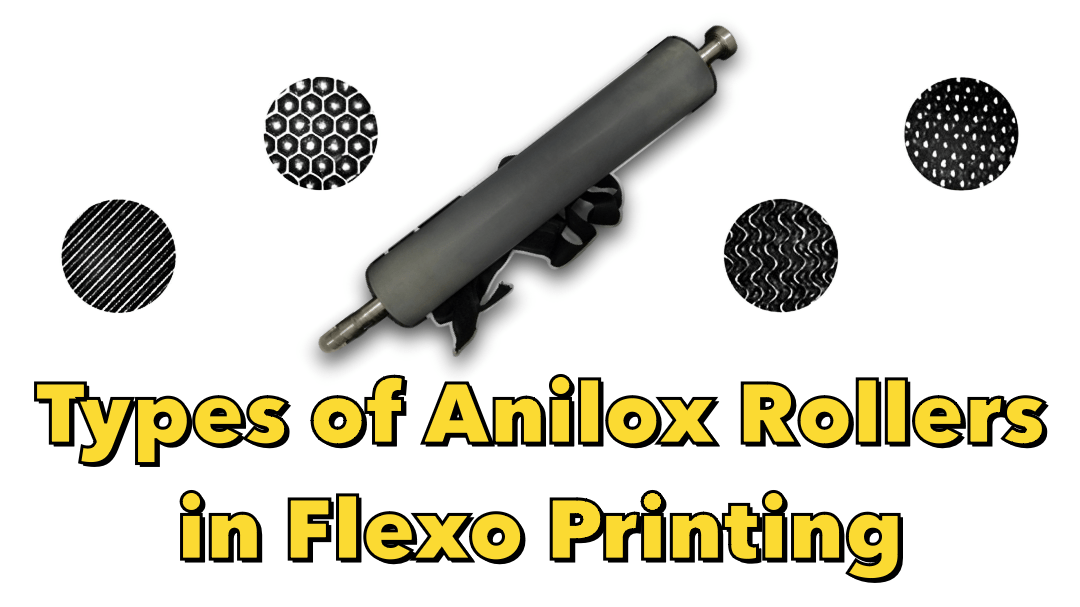

Exploring Anilox Roller Varieties

Print operators select an anilox roller based on the intricacy of the intended images. Differential line screens on anilox rolls influence ink flow: higher line screens dispense more ink onto the paper web but are prone to quicker clogging due to their fine nature. Operators regulate ink flow by adjusting pressure on the anilox roll. In general, anilox rollers are distinguished by the following three primary parameters:

Line screen (LPI, lines per inch)

Defines the density of lines on the anilox roll. In metric units, however, LPC (lines per centimetre) is used, where 1 LPC approx. equals to 2.54 LPI.

Cell angle

Determines the angle of the anilox cells on the roll, noted with the shape of cells and the angle between the line connecting the centres of the adjacent cells and the horizontal direction, such as 60° hex.

Cell volume (BCM, billion cubic microns per square inch)

Specifies the cell volume within the anilox roll. In metric units, however, cm³/m² is used, where 1 cm³/m² approx. equals to 1.55 BCM.

When ordering or handling an anilox roll, both users and suppliers pay heed to these parameters. The printing specifications for each job must align with the anilox roller’s characteristics, ensuring optimal printing outcomes.

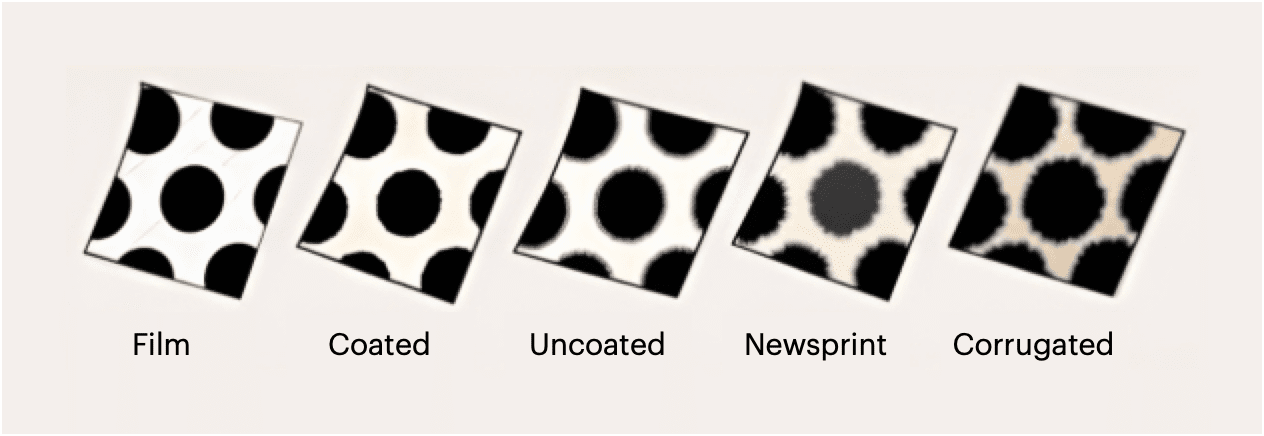

Choosing Anilox Rollers Wisely

Prior to selecting an anilox roller, a construction sheet detailing essential information for each print job is imperative. This includes parameters specific to the printing press. Anilox rollers are commonly identified by line screen distribution (LPI) and cell volume (BCM), ensuring compatibility within the printing process.

For instance, if one printing unit uses 600 LPI/1.8 BCM anilox rollers for the red plate, subsequent units may employ different specifications. In such cases, selecting anilox rollers with the closest match in parameters becomes crucial for consistent printing quality. Therefore, with two options 500 LPI/3 BCM and 700 LPI/1.5 BCM available, the latter option is preferable.

Contrary to popular belief, prioritising shallower cell anilox rollers may not always yield the best results. The focus should lean towards higher LPI to ensure superior ink transfer and drying processes, leading to impeccable print density.