It’s no secret that large-scale printing operations have long been popular. But would it surprise you to learn that tire companies have long supplied essential components of the printing processes?

To create their version of today’s image carriers, the first flexo printing operations used molded rubber plates. Before the popularity of flexo printing skyrocketed (about four decades ago), print houses relied on tire manufacturers’ rubber compounds to create these molded rubber plates.

As flexographic printing gained popularity, new manufacturers began developing specialized compounds designed specifically for printing. These same companies eventually developed extrudable compounds, which allowed the entire cylinder or sleeve to be covered directly.

Flexo operations today can create their finished products using elastomer sleeves, photopolymer plates, or both. While some print houses and manufacturers dismiss elastomer sleeves as “yesterday’s technology,” the research and technology behind them are far more advanced and comprehensive than photopolymer, resulting in higher-quality prints.

Differentiating Elastomers and Photopolymers: A Detailed Analysis

Before we get into the capabilities and advantages of elastomer-blend sleeves versus photopolymer plates, it’s important to understand what each is. An elastomer is a polymer that is either natural or synthetic and has elastic properties. This indicates that it is (relatively) soft and flexible.

A photopolymer is a resin material whose properties change when exposed to light. Typically, a process called photopolymer coating is used to harden a material by applying it to a metal plate and exposing it to light. When light is applied to the “imaged areas” of a photopolymer, the resin is hardened.

Following the curing of the imaged areas, a specialized chemical treatment removes the coating from the non-imaged areas, leaving only the imaged areas to ink receptive. The first major distinction between elastomer-blend sleeves and photopolymer plates is durability. Elastomer sleeves are typically two to three times as durable as other image carrier materials (including photopolymer).

Sleeves, as opposed to photopolymer plates, can be manufactured using corrosion-resistant elastomer blends that can withstand aggressive inks (such as those that contain a high quantity of acetate or that use unique solvents). While using photopolymer in the construction of your image carrier has advantages (quick manufacturing time, very light vignettes), the advantages of integrating elastomer-blend image carriers are far superior and include:

- Long runs

- Bright color

- Specialty or adhesive inks

- High accuracy

- Abrasive substrates

- Wide format web designs in large format

- Varying repeats

- Embossing

- Tight registration

- High temperature

- High solvents

- Conductivity

- Foil stamping

- Lamination

- Quicker registration

- Reduce press changeover time by eliminating plate mounting time

- Increased press speed by reducing plate bounce and eliminating plate lift

Why Elastomers are the Preferred Choice for Most Companies

When it comes to flexo printing operations, most companies are committed to producing long-lasting, yet environmentally friendly products. In general, elastomers outlast photopolymers in terms of:

- Abrasion resistance

- Heat resistance

- And the ability to withstand solvent inks

Elastomers wear better and have a longer run-life than photopolymers due to their strength and durability. The longer production life eliminates the need for additional plates for long runs and repetitive jobs.

Because there is no washout waste and they can be cleaned after engraving with simple soap and water, elastomer-covered image carriers are considered more environmentally friendly. Photopolymer plates and sleeves, on the other hand, necessitate a lengthy processing sequence that includes:

- UV back expose,

- Mask ablation,

- UV image exposes,

- Washing stage,

- Drying stage,

- UV final exposure

These processes take a long time and introduce new variables at each stage. Direct laser engraves elastomer-covered image carriers, eliminating the variable of UV light exposure with photopolymer plates. Elastomers can be ordered in a wider range of types and durometers for application-specific jobs, allowing them to be fine-tuned or chosen for the customer’s specific application.

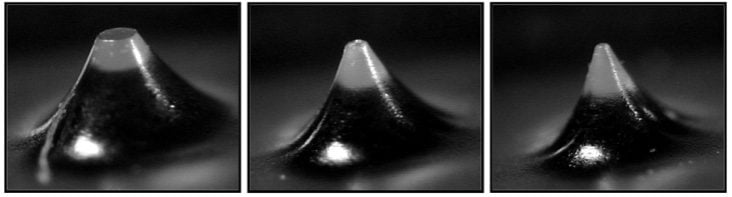

When compared to photopolymers, elastomer-covered image carriers have a “textured” surface, allowing for more surface area for the ink to collect and thus applying a slightly thicker ink film. Sleeves and cylinders covered in elastomer have always provided a true “flat-top dot”*. All of a company’s compounds are proprietary and have been tested to determine the following:

- Various solvent resistance

- Wear resistance

- Surface Tension

- Line Strength

- Ozone Resistance

- Resilience

- Heat Resistance

In general, elastomers outlast photopolymers and can be revulcanized (reused) as long as an unusual issue (such as cracks, delamination, or warping) does not occur.

Elastomer vs Photopolymer | How to Choose the Best Elastomer-Blend

Different compounds are required for different applications. Printing with UV or inks containing aggressive solvents, for example, will necessitate a solvent-resistant compound, whereas printing on a coarse or non-woven substrate may necessitate a tougher compound (such as Nitrile).

In adhesive and varnish applications, a compound with release properties, such as silicone, may be required. Heat-resistant compounds may also be required for heated cylinders.

When it comes to purchasing an image carrier, it is obvious that several factors must be considered. Working with an advanced manufacturer that offers specialized blends for specialized jobs is critical for the success and longevity of your print job. Most companies tend to work closely with their customers to determine the best compound for their specific applications.