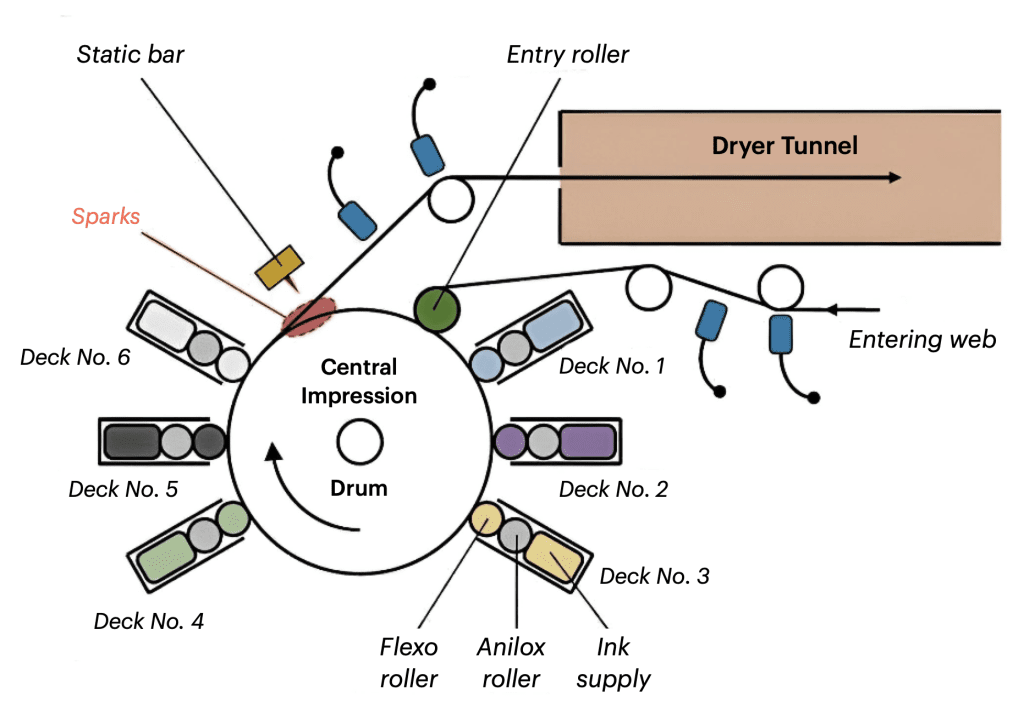

What is central impression drum?

Central impression drum is sometimes referred to as a drum press, common impression press, or CI press.

The press itself consists of a single steel impression cylinder positioned in the main press frame within which the decks are arranged around a large, full-sized impression cylinder.

© Anyflexo

© AnyflexoIt could be made of double-walled steel, cast iron, or a combination of both. A heating device or a cooling device will regulate the drum’s temperature in either case.

Advantages of CI presses

CI presses are commonly produced longer, roll-to-roll runs at higher speeds. The main advantage of this set-up is its higher output capacity – faster speeds plus a wider web width equals more impressions per output and a tighter register tolerance.

Flexography markets have improved throughout the years. The product expected from a CI press has been enhanced to high levels of excellence, which has forced press manufacturers to hold tighter tolerances regarding CI drums.

As a result of its ability to hold an excellent register, the central impression cylinder press has become the industry’s mainstay.

Due to the complexities of graphic designs and the steady demand for quality process printing, the CI’s positive register capability is ideal for all kinds of substrates.

Today, the most common press is still the six-color central impression press, but it is being replaced by an eight-color CI press. Even ten-color CI presses are being now built.

Disadvantages of CI presses

CI technology has some disadvantages. The limitations include set maximum print decks and limited coating, laminating, and drying options, as well as other finishing operations.

In the case of tubular film printing, the central impression press has not been used for printing both sides of a web in one pass through the press.